High-Tech Thermoformer Takes Aim at Injection Molding

Kintz Plastics is not your typical thermoformer.

Kintz Plastics is not your typical thermoformer. This high-tech industrial manufacturer, nestled in rural upstate New York, is an injection molder’s worst nightmare. Kintz is one of a growing group of thermoformers that specializes in high-precision products for the medical, computer, and transportation industries. Molders are looking over their shoulders at companies like Kintz, which use pressure forming and CNC trimming/routing to produce the complex geometries and tight tolerances that were once the exclusive domain of injection molding. “We do the difficult stuff, things that run-of-the-mill thermoformers have problems with,” says president Wynn Kintz. And they are doing it with lower cost machinery and tooling than injection molders.

This heavy-gauge thermoformer leads the attack on injection molding from a relatively remote location in Howes Cave, N.Y. Since its creation in 1976, the company has been forced to be self-sufficient, thus making it a one-stop shop for leading OEM customers. In the last three years, Kintz’s multi-million-dollar investment has included a new 30,000-sq-ft technical center with design and engineering capabilities. Other services include moldmaking, painting, screen printing, ultrasonic inserting, and bonding.

CNC assistance

A multi-component enclosure for a biomedical part called a “vein viewer” is the latest example of how Kintz is competing with injection molding at lower tooling cost. The low-volume product (500 to 1000/yr) consists of six pressure-formed FR-ABS panels that encase the unit. Kintz not only offered a more economical method than molding but also shorter time to market–just six weeks.

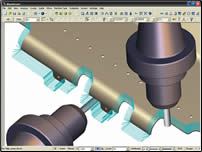

A key element of Kintz’s high-tech reputation is its extensive stable of 11 three-axis CNC trimmers and 12 five-axis CNC units. Kintz programs tool paths for the trimmers with the aid of Mastercam software from CNC Software, Tolland, Conn. The software simplifies and improves the quality of CNC programming, making it faster and easier to produce formed parts with tight tolerances and strict aesthetic requirements.

‘Jumbo’ forming

Large parts are another growing market where Kintz has made considerable investment in equipment and application development to expand its business. A new four-station rotary thermoformer can form parts up to 9 ft wide x 13 ft long x 5 ft deep. This “jumbo” machine, which Kintz says is the largest thermoformer in the eastern U.S., has a 2200-sq-ft footprint and can produce one-piece bathtubs, panels for mass transit and off-road vehicles, and components for kiosks and point-of-purchase displays. One of the most-impressive applications so far is a 5 x 8 ft storm-drain vessel made of 0.5-in.-thick HDPE to replace cement.

Another high-growth area for Kintz is twin-sheet forming as a low-cost alternative to blow molding for rigid, hollow parts. “Twin-sheet has been a well-kept secret but designers and engineers are becoming more aware of the process as more projects are done,” says Kintz. A recent application used twin-sheet FR-ABS for door covers that enclose a medical testing apparatus. This was a less costly and lighter alternative to the previous fiberglass version.

With a workforce of 100, after adding 20 employees in the past two years, Kintz is entering a new growth phase. A focused effort on transportation will make use of new low-smoke materials for automotive, aerospace, and rail applications. In the first quarter of 2007, Kintz will launch an innovative system using vacuum and pressure forming to make carbon-fiber reinforced composites for aerospace.

Related Content

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreIngenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.

Read MoreWinners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More