How Parkway Makes Stock Jars Into a Custom Business

This family firm distinguishes itself in a commodity market by offering numerous ways to customize its stock products.

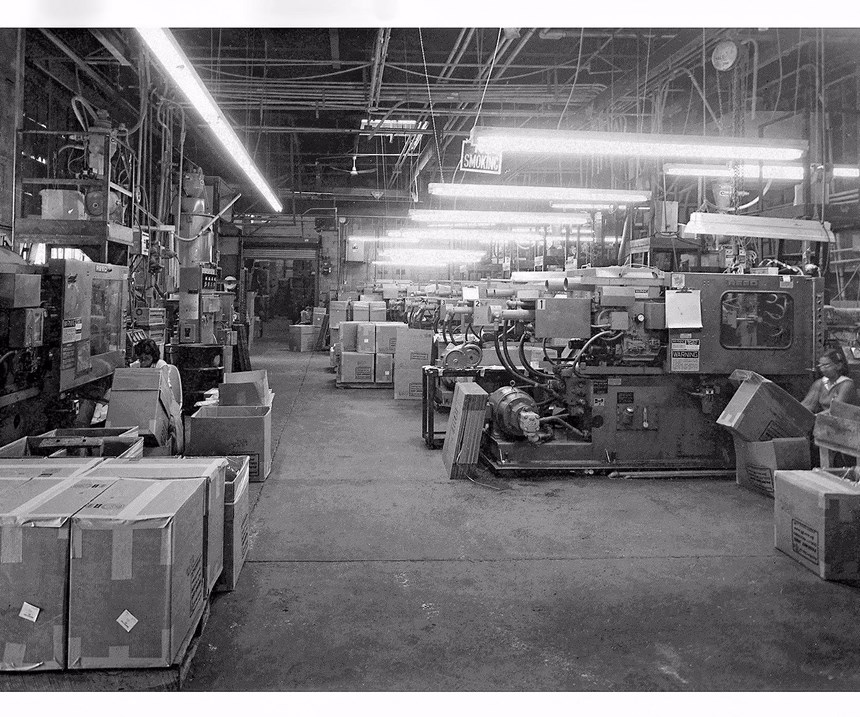

Parkway Plastics prides itself on having been the first to introduce stock plastic jars back in

the early 1950s. Stock jars and caps remain the mainstay of its business—around 80%,

according to Ned Rowan, v.p. of sales & operations. But it depends on your definition of

“stock.” When you consider all the ways in which customers can add distinctive touches to

so-called stock containers, at least 40% of the firm’s business is to some degree customized.

And that’s a big part of what makes Parkway different from its competitors.

“We’re very flexible. We make it easy to customize our stock products—for example,

through decorating, labeling, or molded-in logos. And we’re known for our custom colors,”

explains Kirstin Rowan Kelly, secretary treasurer. She’s also Ned’s sister, and the two of

them constitute the third generation to own and manage this family firm. That element

of “family”—which embraces everyone down to machine operators—is another distinguishing

trait of this 65-year-old processor.

CREATING A NEW PLASTICS MARKET

It wasn’t always about jars. Company founder Edward W. Rowan, Sr. graduated from Yale in 1935 with an engineering degree. Over the next two decades, he gained experience in diverse fields: designing cardboard boxes; custom injection molding during World War II—such as the first plastic sextant for the Navy; molding fishing lures and plastic toys; and designing and building plastic injection molds. In 1954, he incorporated Parkway Plastics in Piscataway, N.J., to meet the new demand for lightweight, unbreakable plastic storage jars. “We made the first plastic stock jars in the market,” says his granddaughter, Kelly.

“We were the first to

bring stock plastic

jars to the market.”

Rowan’s son, Edward W. Rowan, Jr., became president of the firm in 1969. He and his children, Ned and Kirstin, run the business today. It has grown to more than $10 million annual sales, operating in a plant that has expanded to 40,000 ft2 and employs anywhere from 45 to 65, hiring additional temporary labor during times of peak demand. Parkway’s current manufacturing area can hold between 16 and 18 injection presses, generally between 200 and 300 tons clamp capacity. The facility and surrounding property have room for further expansion, if needed.

Parkway updates its machines regularly, and the oldest was purchased in 2006. Today’s lineup includes mostly all-electric presses—Milacron Powerline, Milacron Fanuc Roboshot, and Niigata models—as well as brand-new Milacron Magna T hybrid electric/hydraulic machines.

All of Parkway’s machines, except for those dedicated to cap molding, are outfitted with Wittmann Battenfeld robots and outfeed conveyors in precisely laid-out cells dedicated to repeatable and interchangeable production of Parkway’s product line. At the end of the outfeed conveyors, parts arrive for manual inspection and packing into shipping containers.

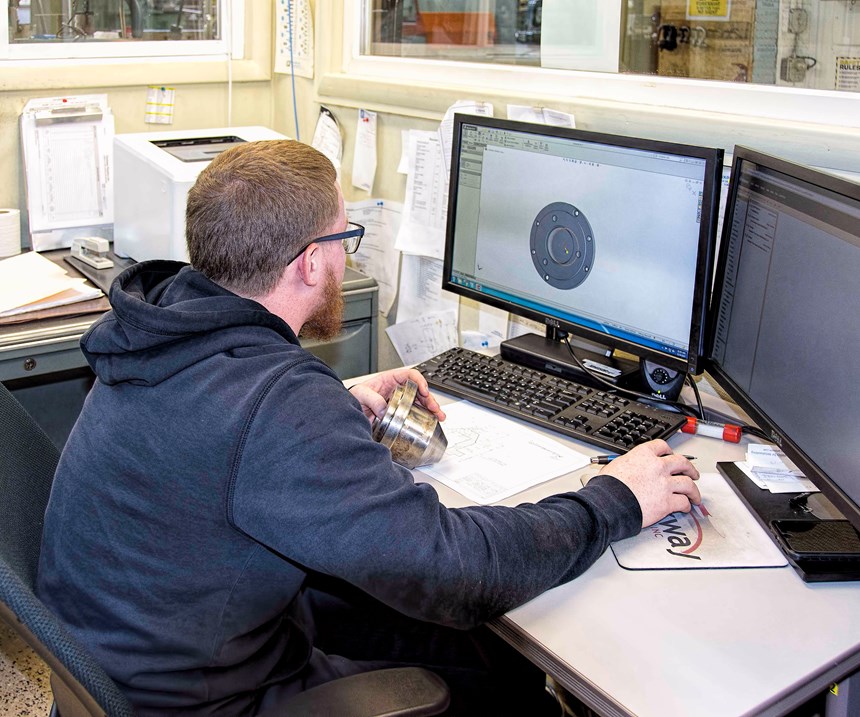

Parkway offers secondary operations such as labeling, shrink sleeves, hot stamping, and screen or offset printing. It also has SolidWorks CAD stations for product, mold, and component design. There’s a sizeable toolroom for mold maintenance, repairs, and production of new cores, cavities, plates, and other mold components. When needed, Parkway also uses outside tool shops to avoid bottlenecks.

“We use a lot of insert molds with interchangeable cores and cavities,” explains Ned Rowan. Mold bases are dedicated to product families of up to 10 different variations. This is not only economical, but speeds job changeovers, of which Parkway performs two or three a day. “A new product typically starts with just a core and cavity. We won’t buy a mold base for it until it becomes a volume item,” Ned explains.

The toolroom is also important to Parkway’s new offer to custom-tailor products with molded logos or other decoration. The firm announced this “in-mold customization” capability in mid-2016.

All the firm’s molds are of 420 stainless steel. Some molds dating back to the 1970s are still running, but Parkway develops new variants frequently—changing a thick wall to thin, a straight bottom to a rounded one, or an overhanging cap to one that’s flush with the jar wall. Parkway’s catalog includes roughly 500 SKUs for jars and caps, which can be customized to yield many more options. In the past 18 months, the company has launched more than 20 additional SKUs, and Parkway is exploring how to ramp up the pace of new-product development even further. That’s one reason that Ned Rowan is thinking about supplementing the toolroom’s lathes and milling machines with a CNC machining center.

Parkway’s molds have up to 24 cavities for caps and two to 16 cavities for jars, which range from 1/8 oz to 40 oz. The firm uses mainly hot runners, which, like the mold bases, are dedicated to mold families for similar products and to a single material to minimize the need for purging. Among them are three valve-gate systems, which Ned Rowan favors because they make a cleaner gate with less vestige.

His job of managing operations is facilitated by two monitoring systems. One is for plantwide production monitoring, used mainly to check whether machines are maintaining cycle times. Data is uploaded to the plant’s central computer, which managers can access remotely. There’s also a system of 32 cameras strategically placed throughout the plant for remote monitoring of security, production, and shipping. Personnel can even access the camera feeds on their smartphones. Ned says, “You can easily see if a machine is up or is down, a mold has been set up, whether an item has shipped, and how much production has been run.”

“We really enjoy working

with customers in

the beginning of a

product’s life cycle, at

the development and

engineering stages.

That’s where we offer

the most value.”

MANY WAYS TO CUSTOMIZE

The plant has three silos, one for each of its three main materials—natural or clarified PP and crystal PS. However, Parkway also processes some HDPE, SAN, and PET. Some customers, particularly in the pharmaceutical industry, require special grades, and several use post-consumer recycled (PCR) HDPE—up to 100% PCR in some products.

Parkway also offers up to 175 custom colors, based on masterbatches, which are custom matched by an outside firm. And it offers EcoPure additive from Bio-Tec Environmental, Cedar Crest, N.J. (goecopure.com), which reportedly enhances biodegradability of a wide range of plastics.

Ned Rowan says Parkway is one of several major producers of similar lines of stock plastic jars. “Parkway, however, has its own proprietary options that give it points of differentiation, including our deeper offering across all styles of injection molded jars,” he notes. “Parkway has always had a strong footprint in the cosmetics market, but also has many customers in other industries such as pharmaceuticals, surgical products, paints, epoxies, labware, consumer products, confectionery, spices, crafts, and industrial supplies.”

Says Edward W. Rowan, Jr., “Since my father founded Parkway, it’s been so rewarding being able to manufacture goods that have touched so many facets of daily life, in many unseen and surprising ways—whether we’ve packaged heart valves, spaceship epoxy, or children’s paint.”

Offering a high degree of customer service and customization is another distinguishing trait. “As our competition has grown larger through multiple acquisitions, customer service tends to suffer,” says Ned Rowan.

“For example, some of our customers require extra QC checks,” adds Kelly, and Parkway has experience prepping its manufacturing cells into “portable” clean rooms when needed. While these are not certified clean rooms, they enable Parkway to meet the quality objectives of pharmaceutical customers.

“We really enjoy working with customers in the beginning of their product’s life cycle, during their development and engineering stages,” notes Kelly. “That’s where we offer the most value. We can help with product design and even with refining label design.”

Ned Rowan adds that Parkway aims for small- to medium-volume orders—in the millions or tens of millions of parts, but not hundreds of millions, “which would occupy too much of our capacity and floorspace.” Parkway works with an outside vendor to produce 3D-printed models for customers of products in development.

Kelly says another competitive advantage for Parkway is its e-commerce platform, a convenience not offered by most of its competitors. The platform includes an online chat box that can be monitored at all hours and has helped customers better understand and utilize the website’s features.

A ‘FAMILY’ FEEL

While Parkway seeks to distinguish itself through external customer relations, its internal employee relations are considered equally important to its success. Parkway is a family firm in more than one sense. One gets a hint from the company website, which introduces the company “team” in a highly unusual fashion, with names and photos of everyone from the chief officers down to “Parkway’s Finest”—the foremen and toolroom, shipping, and maintenance staff, and even the first-, second-, and third-shift operators.

“Everyone is important here, because

everyone becomes part of a family.”

“Everyone is important here,” asserts Kelly. “I personally meet everyone in the hiring process, regardless of whether we are hiring a manager, a lower-level team member, or temporary labor. We schedule interviews with the staff, have them meet with a foreman. We want to find out if they’re a good fit here, if they’re a team player. Because everyone here becomes part of a family.”

At least a dozen of Parkway’s employees have worked there more than a decades, and one third-shift operator recently celebrated 40 years on the job. “We have a 401K program, profit-sharing bonuses, and medical-dental-vision coverage for permanent employees, no matter how new on the job.” says Kelly. These account for only about half the staff, the rest are classified as “temporary” workers supplied through agencies. “But we only use agencies that offer health benefits,” Kelly notes. “And we offer paid holidays even for the temporary labor—which is pretty unusual. In addition, we sponsor monthly lunches for all employees of all shifts. We have holiday pot-luck meals where employees bring in dishes and we decorate the lunchroom.

“We operate in three languages—English, Spanish, and Gujarati (a language of western India). Even our 20-point QC inspection sheets are in all three languages. We cross-train everyone to do different kinds of tasks. Seasoned people train new ones. It not only makes them care more because they’re not doing the same thing every day, but they see how what they do affects others doing different jobs.”

For example, workers are trained in packing boxes, doing QC checks (part weight, color, clarity, gate quality, and label placement), assisting in cap lining, assisting the foreman. Molding shop foremen may even be called on occasion to work in the toolroom. “We want people who like to learn new things,” says Kelly. “We train people to realize that this is not just an empty jar, because somebody’s—maybe even your mother’s—medicine or face cream will go into it. We want trainees to feel connected to the end-user.”

Related Content

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More