How to Select and Process High-Density Thermoplastic Materials

Choosing and working with high-density materials requires special knowledge in the areas of applications, mold design, and processing. Here are best practices that should increase your understanding.

Two factors are accelerating the use of high-density thermoplastic material formulations in diverse applications such as radiation shielding, projectiles, appliance components, and packaging. First, environmental, health, and safety concerns are driving demand for lead replacement. Second, there is a need to increase part density without the use of metals, which restrict design freedom and are typically more costly and complicated to process than polymer compounds. High-density thermoplastic (TP) compounds offer valuable benefits, including sustainable, non-toxic formulations, an excellent balance of properties, and the ability to be melt processed using common methods.

However, choosing and working with these materials requires specialized knowledge. For example, selection of the polymer matrix and the type of high-density filler additive has a major effect on the properties of the material and how well it meets application requirements over the life cycle of the part. Also, many nuances must be considered when processing high-density formulations, including tool design, molding method, and adjustments to factors such as barrel temperature, processing speeds, and even materials and parts handling.

This article provides practical guidance and suggested practices to increase your understanding of high-density polymer formulations, and where and how to use them. It will help you choose the right material for your application, and optimize mold design and processing.

Weighing in on High-Density formulations

High-density TP formulations that replace lead and other metals have a high specific gravity between 2 and 11, in contrast to unfilled plastics such as polystyrene (PS), which have a specific gravity of about 1.0. Even 40% long-glass reinforced nylon 66 has a specific gravity of only 1.74. High-density formulations offer a major boost in part mass, but avoid many of the drawbacks of metal, including design restrictions, higher costs, and more-complex processing and secondary operations such as machining.

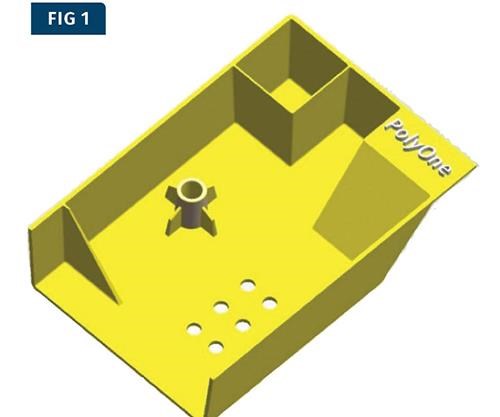

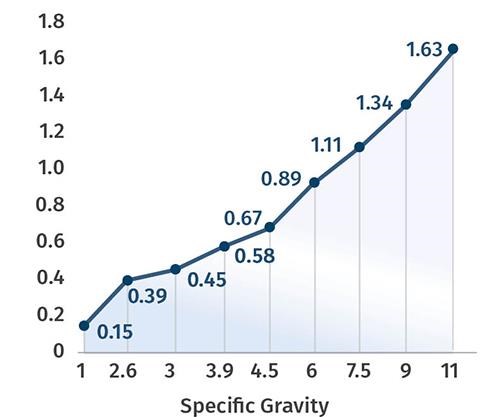

By replacing a traditional plastic with a high-density material, you can keep the same part geometry while adding weight and heft for balance, momentum, or a perception of higher quality. Figure 1 shows how a high-density formulation can increase part weight. This 4 x 6 in. box has various geometries, such as float pads on the bottom. When made with a traditional plastic like PS, it weighs about 0.15 lb. Using the same part design with the same volume, but changing the density of the material will increase part weight (see Fig. 2). By choosing a material with a specific gravity of 2.6, part weight will increase to 0.4 lb. A specific gravity of 6 will boost part weight to 0.67 lb. If we go all the way to a specific gravity of 11, that same part is now approaching 2 lb. This represents a 987% increase in part weight from the original PS to a high-density formulation with a specific gravity of 11.

High-density TP materials can also be formulated to be non-toxic compared with lead metal, contributing to safety and sustainability initiatives, and provide a balance of tensile strength, flexural modulus, and heat-deflection temperature (HDT). They are melt processable using common molding and extrusion methods.

Get the Lead Out

Lead is a concern for environmental, safety, and health reasons. It is tightly regulated under numerous laws and directives, including the European Union’s Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives, and California statutes covering plumbing and water safety.

California also restricts the use of lead bullets and lead shot to protect wildlife that eat carrion. In human health, especially for babies and young children, lead exposure can cause irreversible neurological damage that leads to developmental difficulties. There are also risks to workers using products made with lead, as well as disposal concerns. A few years ago, OSHA lowered the allowable level of airborne particulates in machine shops that use lead.

Given all these concerns, high-density polymer formulations are replacing lead in applications such as radiation shielding for nuclear medicine and X-ray equipment and in non-toxic ammunition.

There are many scenarios for using high-density formulations to replace metals other than lead. The goal is often to add weight for performance reasons, such as better balance for sporting goods, or to indicate higher quality. For example, appliance manufacturers are replacing lightweight zinc die-cast knobs with high-density TP materials to appeal to consumers’ perception that heavier weight means greater value.

Choosing the Right Material

As with any plastic, the first step in material selection is determining the application’s requirements. These range from physical, mechanical, and electrical performance to environmental exposures (temperature, UV light, chemicals) and aesthetics. Applicable regulatory requirements and industry standards also must be met.

Fortunately, there are multiple high-density material options available, thanks to the ability to combine different resin matrixes with different types of high-density additives such as minerals and metal powders. For example, a high-density compound can be based on a soft TPE, if needed. Figure 3 shows a TPE with a Shore A hardness of 35 to 40, specific gravity of 8 and low tensile strength of 150 psi.

On the other end of the spectrum is polyether ether ketone (PEEK), offering high tensile strength, modulus, and HDT. A PEEK-based material with a specific gravity of 6 delivers a tensile strength of almost 15,000 psi.

Figure 4 displays specific-gravity ranges for different types of applications. For instance, radiation-shielding applications may require materials with a specific gravity in the 6 to 11 range, while some low-energy shielding needs materials with specific gravities of only 2 to 5.

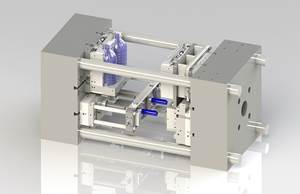

Designing the Mold

High-density compounds have specific properties that impact mold design. Although you can follow conventional design practices and use a cold-runner or hot-runner system, and choose two- or three-plate molds, some adjustments may be required. One is the type of steel used in the mold. For lower-specific-gravity materials and lower-volume operations, a P20 steel is a good standard. As you advance in specific gravity and volume, a more abrasion-resistant material, such as an S7, H13, or 420 steel, is needed. Certain high-density additives can affect softer tools.

High-density additives also increase thermal conductivity of the matrix; so a short flow length should be used to promote complete mold filling and prevent the flow front from freezing up too early and causing a high-pressure situation. Avoid Small runners; a slightly larger diameter is recommended. In cold-runner designs, a full-round system can provide a homogeneous melt path for the material. Trapezoidal configurations can be used to avoid sharp edges, but angled tunnel gates can create problems. High-density materials tend to be more brittle due to their high loading of dense additives, and if flexing is too great on demolding, they will crack and break.

If using a hot-runner system, ensure it offers mechanically and thermally balanced melt flow. Internally or externally heated elements are both fine, but because of the high temperature, H13 steel is recommended. Also, higher viscosity and abrasion from high loadings of the high-density additives can be somewhat harsh on heating elements, so ensure they are robust. Finally, avoid valve gates because high-density materials do not provide as clean a shut-off as traditional plastics.

Other guidance on gate design includes keeping the flow front open as long as possible to minimize shear. Tab gates, large fan gates, large tunnel, and diaphragm gates are acceptable, as long as they provide 60-80% wall thickness. A thicker wall will allow the flow front to remain open longer. If gates are too small (submarine or pin gates), there is a good chance of freeze-up before the part is fully filled.

High-density polymers do not require exotic cooling systems. You can use U channels, baffles, and bubblers. Because of the higher thermal conductivity of the material, in many instances the amount of cooling time can be reduced.

Finally, highly filled materials call for uniform pressure across the part when it is pushed off the core or out of the cavity. This will help avoid cracking due to an imbalance in the ejector system. Also, minimize falling distance of ejected parts onto a bin or conveyor. High-density additives can reduce the properties of the plastic (tensile strength, impact resistance) and robotic or manual handling may be needed to reduce risk of damage.

Processing High-density Materials

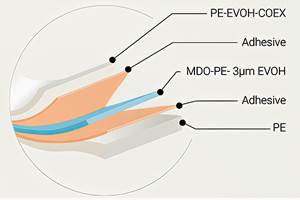

Injection molding is the most common method for processing high-density TP formulations, but profile extrusion, sheet extrusion, and thermoforming can also be used. However, these materials are not well suited to extrusion blow molding (poor melt strength) or rotational molding (non-uniform wall thickness).

Here are some key processing tips:

• Use a higher barrel temperature to reduce viscosity and injection pressure.

• Minimize the material in the barrel and hot-runner system by cleanly flushing it out of the hot runner in every shot.

• Use moderate to fast injection speeds to minimize skin-layer build-up and avoid inconsistent fill.

• In extrusion, use moderate screw rpm and a coarse screen pack to reduce pressure in the die.

• Control mold temperature to provide uniform heating. Water and/or oil heating is usually adequate for these materials.

Another consideration is materials handling. The heavier weight of these materials means a vacuum loader will not be able to handle those with a specific gravity above 5 or 6. An auger system or even hand loading may be necessary.

ABOUT THE AUTHORS

Jean-Paul Scheepens has international experience in operations management, mergers and acquisitions, continuous process improvement, supply-chain planning, and marketing. As senior product manager at PolyOne in Avon Lake, Ohio, he is responsible for the growth and profitability of the Specialty Engineered Materials portfolio. Contact: (440) 930-3057; jean-paul.scheepens@polyone.com; polyone.com.

Paul Hans has more than 26 years of experience in the polymer industry and holds a Ph.D. in Polymer Science. He is a senior product scientist at PolyOne and develops highly engineered specialty polymer materials to improve performance and productivity. Contact: (440) 930-3216, paul.hans@polyone.com.

Related Content

Recycling Terminology Can Be a Minefield, So We Should Tread Lightly

Loose propagation of terms like “recyclable” and “compostable” has already brought down government regulations on labeling. The plastics and packaging industries should take that to heart with other recycle-related language. Like “monomaterial” for example.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More