Follow These Tips to Select the Right Pelletizer

Start by assessing the status quo, as well as defining future needs. Develop a five-year projection of materials and required capacities. Short-term solutions very often prove to be more expensive and less satisfactory after a period of time. Most of all, know your options.

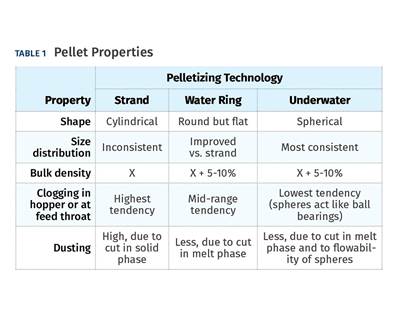

Pellets may be “only” an intermediate product, but their size, shape, and consistency matter in subsequent processing operations.

This becomes even more important when considering the ever-increasing demands placed on compounders. No matter what equipment they currently have, it never seems suited for the next challenge. An increasing number of products may require additional capacity. A new polymer or additive may be too tough, soft, or corrosive for the existing equipment. Or perhaps the job requires a different pellet shape. In such cases, compounders need in-depth engineering know-how on processing, and close cooperation with their pelletizing equipment supplier.

The first step in meeting such challenges begins with equipment selection. The most common classification of pelletizing processes involves two categories, differentiated by the state of the plastic material at the time it’s cut:

•Melt pelletizing (hot cut): Melt coming from a die that is almost immediately cut into pellets that are conveyed and cooled by liquid or gas;

•Strand pelletizing (cold cut): Melt coming from a die head is converted into strands that are cut into pellets after cooling and solidification.

Variations of these basic processes may be tailored to the specific input material and product properties in sophisticated compound production. In both cases, intermediate process steps and different degrees of automation can be incorporated at any stage of the process.

To find the best solution for your production requirements, start with assessing the status quo, as well as defining future needs.

To find the best solution for your production requirements, start with assessing the status quo, as well as defining future needs. Develop a five-year projection of materials and required capacities. Short-term solutions very often prove to be more expensive and less satisfactory after a period of time. Though almost every pelletizing line at a compounder will have to process a variety of products, any given system can be optimized only for a small range of the entire product portfolio.

Consequently, all the other products will have to be processed under compromise conditions.

The lot size, in combination with the nominal system capacity, will have a very strong impact on the pelletizing process and machinery selection. Since compounding production lots tend to be rather small, the flexibility of the equipment is often a big issue. Factors include easy access for cleaning and service and the ability to simply and quickly move from one product to the next. Start-up and shutdown of the pelletizing system should involve minimum waste of material.

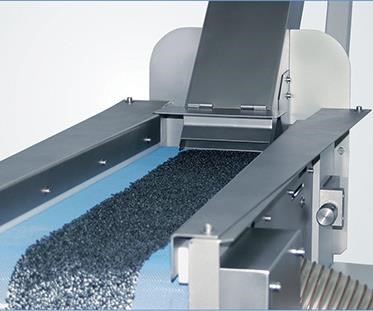

A line utilizing a simple water bath for strand cooling often is the first option for compounding plants. However, the individual layout can vary significantly, due to the demands of throughput, flexibility, and degree of system integration. In strand pelletizing, polymer strands exit the die head and are transported through a water bath and cooled. After the strands leave the water bath, the residual water is wiped from the surface by means of a suction air knife. The dried and solidified strands are transported to the pelletizer, being pulled into the cutting chamber by the feed section at a constant line speed. In the pelletizer, strands are cut between a rotor and a bed knife into roughly cylindrical pellets. These can be subjected to post-treatment like classifying, additional cooling, and drying, plus conveying.

If the requirement is for continuous compounding, where fewer product changes are involved and capacities are relatively high, automation may be advantageous for reducing costs while increasing quality. Such an automatic strand pelletizing line may utilize a self-stranding variation of this type of pelletizer. This is characterized by a cooling water slide and perforated conveyor belt that replace the cooling trough and evaporation line and provide automatic transportation into the pelletizer.

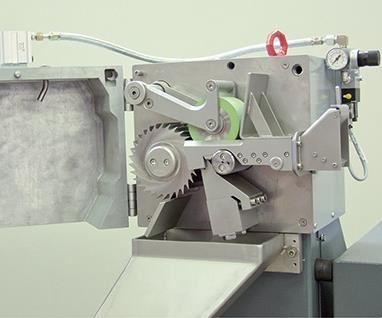

Some polymer compounds are quite fragile and break easily. Other compounds, or some of their ingredients, may be very sensitive to moisture. For such materials, the belt-conveyor strand pelletizer is the best answer. A perforated conveyor belt takes the strands from the die and conveys them smoothly to the cutter. Various options of cooling—water spray, misters, compressed-air Venturi dies, air fan, or combinations thereof—allow for a good deal of flexibility.

When to go Underwater

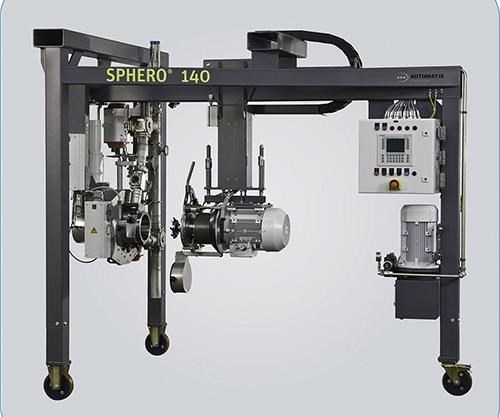

When the preferred pellet shape is more spherical than cylindrical, the best alternative is an underwater hot-face cutter. With a capacity range from from about 20 lb/hr to several tons/hr, this system is applicable to all materials with thermoplastic behavior. In operation, the polymer melt is divided into a ring of strands that flow through an annular die into a cutting chamber flooded with process water. A rotating cutting head in the water stream cuts the polymer strands into pellets, which are immediately conveyed out of the cutting chamber. The pellets are transported as a slurry to the centrifugal dryer, where they are separated from water by the impact of rotating paddles. The dry pellets are discharged and delivered for subsequent processing. The water is filtered, tempered, and recirculated back to the process.

The main components of the system—cutting head with cutting chamber, die plate, and start-up valve, all on a common supporting frame—are one major assembly. All the other system components, such as process-water circuit with bypass, cutting chamber discharge, sight glass, centrifugal dryer, belt filter, water pump, heat exchanger, and transport system can be selected from a comprehensive range of accessories and combined into a job-specific system.

In every underwater pelletizing system, a fragile temperature equilibrium exists within the cutting chamber and die plate. The die plate is both continuously cooled by the process water and heated by die-head heaters and the hot melt flow. Reducing the energy loss from the die plate to the process water results in a much more stable processing condition and increased product quality. In order to reduce this heat loss, the processor may choose a thermally insulating die plate and/or switch to a fluid-heated die.

Many compounds are quite abrasive, resulting in significant wear and tear on contact parts such as the spinning blades and filter screens in the centrifugal dryer. Other compounds may be sensitive to mechanical impact and generate excessive dust. For both of these special materials, a new type of pellet dryer deposits the wet pellets on a perforated conveyor belt that travels across an air knife, effectively suctioning off the water. Wear of machine parts as well as damage to the pellets can be greatly reduced compared with an impact dryer. Given the short residence time on the belt, some kind of post-dewatering drying (such as with a fluidized bed) or additional cooling is usually required. Benefits of this new non-impact pellet-drying solution are:

•Lower production costs due to long lifetime of all parts coming into contact with pellets.

•Gentle pellet handling, which ensures high product quality and less dust generation.

•Reduced energy consumption because no additional energy supply is necessary.

Other Pelletizing Processes

Some other pelletizing processes are rather unusual in the compounding field. The easiest and cheapest way of reducing plastics to an appropriate size for further processing might be a simple grinding operation. However, the resulting particle shape and size are extremely inconsistent. Some important product properties will also suffer negative influence: The bulk density will drastically decrease and the free-flow properties of the bulk would be very poor. That’s why such material will only be acceptable for inferior applications and must be marketed at rather low cost.

Dicing had been a common size-reduction process since the early 20th Century. The importance of this process has steadily decreased for almost 30 years and currently makes a negligible contribution to the current pellet markets.

Underwater strand pelletizing is a sophisticated automatic process. But this method of production is used primarily in some virgin polymer production, such as for polyesters, nylons, and styrenic polymers, and has no common application in today’s compounding.

Air-cooled die-face pelletizing is a process applicable only for non-sticky products, especially PVC. But this material is more commonly compounded in batch mixers with heating and cooling and discharged as dry-blends. Only negligible amounts of PVC compounds are transformed into pellets.

Water-ring pelletizing is also an automatic operation. But it is also suitable only for less sticky materials and finds its main application in polyolefin recycling and in some minor applications in compounding.

Influence on Product Properties

Choosing the right pelletizing process involves consideration of more than pellet shape and throughput volume. For example, pellet temperature and residual moisture are inversely proportional; that is, the higher the product temperature, the lower the residual moisture. Some compounds, such as many types of TPE, are sticky, especially at elevated temperatures. This effect can be measured by counting the agglomerates—twins and multiples—in a bulk of pellets.

Choosing the right pelletizing process involves consideration of more than pellet shape and throughput volume.

In an underwater pelletizing system such agglomerates of sticky pellets can be generated in two ways. First, immediately after the cut, the surface temperature of the pellet is only about 50° F above the process water temperature, while the core of the pellet is still molten, and the average pellet temperature is only 35° to 40° F below the melt temperature. If two pellets come into contact, they deform slightly, creating a contact surface between the pellets that may be free of process water. In that contact zone, the solidified skin will remelt immediately due to heat transported from the molten core, and the pellets will fuse to each other.

Second, after discharge of the pellets from the dryer, the pellets’ surface temperature increases due to heat transport from the core to the surface. If soft TPE pellets are stored in a container, the pellets can deform, warm contact surfaces between individual pellets become larger, and adhesion increases, leading again to agglomerates. This phenomenon is probably intensified with smaller pellet size—e.g., micro-pellets—since the ratio of surface area to volume increases with smaller diameter.

Pellet agglomeration can be reduced by adding some wax-like substance to the process water or by powdering the pellet surfaces immediately after the pellet dryer.

Performing a number of pelletizing test runs at consistent throughput rate will give you an idea of the maximum practical pellet temperature for that material type and pellet size. Anything above that temperature will increase the amount of agglomerates, and anything below that temperature will increase residual moisture.

In a few cases, the pelletizing operation may be expendable. This is true only in applications where virgin polymers can be converted directly to finished products—direct extrusion of PET sheet from a polymer reactor, for example. If compounding of additives and other ingredients adds real value, however, direct conversion is not possible. If pelletizing is necessary, it is always best to know your options.

ABOUT THE AUTHOR

Horst Mueller joined Automatik Plastics Machinery GmbH, a leading German manufacturer of plastics pelletizing equipment, in 1997. Mueller is involved in engineering, development, standardization, intellectual property administration, documentation, and marketing.

Related Content

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreHow to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreRead Next

Solve Seven Common Pelletizing Problems

Here's a quick how-to on keeping your pelletizing line churning out quality product.

Read MoreStrand Pelletizing: Follow These Steps to Determine Your Water Bath Length

Use heat-transfer equations as a shortcut to get you in the ballpark of how long your pelletizing water bath should be.

Read MoreFollow These Guidelines to Select the Right Pelletizing System

Which pelletizing system is right for your application? Is the one you’re using today necessarily the right choice for tomorrow? Here’s is an analysis that can help you decide among the three major options.

Read More