Industry Trends Mean New Applications for Established Continuous Mixing System

NPE2024: Farrel Pomini is highlighting the adaptability of its continuous mixer to recycling, bioresin contexts.

Farrel Pomini is presenting its Continuous Mixer as a flexible solution for diverse applications, including mechanical recycling, processing bioderived materials, in support of pyrolysis operations and recycling of tires.

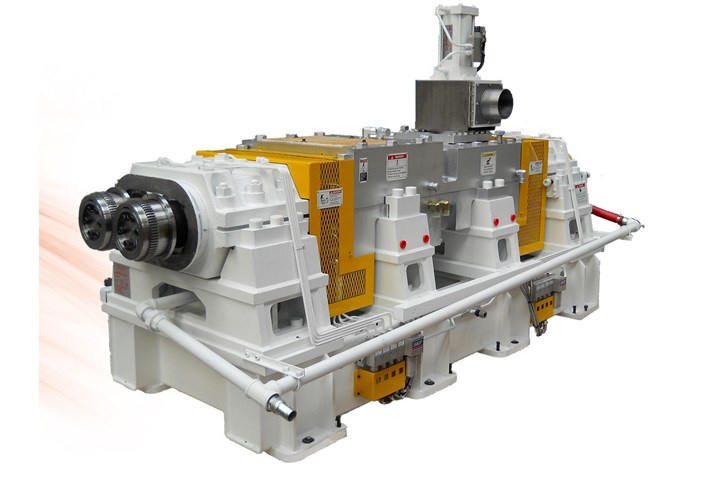

The Farrel Pomini Continuous Mixer. Source: Farrel Pomini

The Continuous Mixer itself was originally launched decades ago, but the company has found new utility as industry trends have changed in recent years.

“Although the market is growing, it’s becoming more difficult for compounders,” says Paul Lloyd, Farrel Pomini president. “For us and for our customers, sustainability usually means an element of new products that are not as straightforward to process as the previous, oil-based products.”

Farrel’s Compact Processor combines the continuous mixer and extruder on a unified frame. Lloyd credits the energy efficiency of the system to this configuration. In mechanical recycling of thermoplastics, each successive cycle adds heat and shear history with the potential to degrade the properties of the polymer. An efficient machine that operates at lower energy reduces the temperature buildup in the material as it is being processed, thereby minimizing the deleterious effects of heat history.

The operating window is also important in processing biopolymers, which are often more temperature sensitive than petroleum-based virgin resin. The Farrel mixer has been used to process PHA, PLA and PBS (polybutylene succinate, a biodegradable polyester). On Thursday, May 9, at 1 p.m., a presentation will cover the development of biobased and compostable compounds by a collaboration between Farrel Pomini, FPInnovations, West Fraser and Good Natured Products.

The system can also play a role in pyrolysis. In a chemical recycling process developed by Lummus Technology, the mixer is used to melt and homogenous plastic feedstocks as a first step. “They don’t care as much about the heat that is being generated, because they are going to a higher temperature anyway to complete the reaction, but they are using our machine for its efficient material intake and homogenization capability,” Lloyd says.

Yet another application for the Continuous Mixer is as part of a pyrolysis process for the recycling of end-of-life tires. One of the materials recovered is carbon black, which Farrel Pomini has shown can then be used to make masterbatches for plastic film or injection-molded products, displacing the need for virgin carbon black as an additive.

Farrel Pomini’s booth at NPE2024 has visual presentations and videos at stations dedicated to various applications such as recycling, traditional compounding and biopolymers, as well as technical specialists to answer questions that arise in each area. “Energy efficiency, flexibility and robustness will be the continuous themes throughout the displays you’ll see, but then they’ll be targeted toward the technology that would be particularly relevent to your field,” Lloyd says.

Related Content

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.