Injection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

There are hundreds of variables to contend with in developing a 24/7 injection molding process, and it can be difficult to decide on which to focus. Some are more important than others, but no matter where you rank a given variable, the fact is the process will not run unless each is controlled to whatever the resin and part need.

My pick this month is melt uniformity, and it should be in your top 10 list of variables. By uniformity I mean not just melt temperature, but melt consistency, meaning no swirls, streaks, or partially unmelted pellets. If you want consistent dimensions and performance 24/7, you must have melt uniformity.

Our focus here is on the difficulty in achieving melt uniformity between amorphous and semi-crystalline resins. These resins melt differently, and a processor needs to understand how each of these polymers melts to obtain melt uniformity.

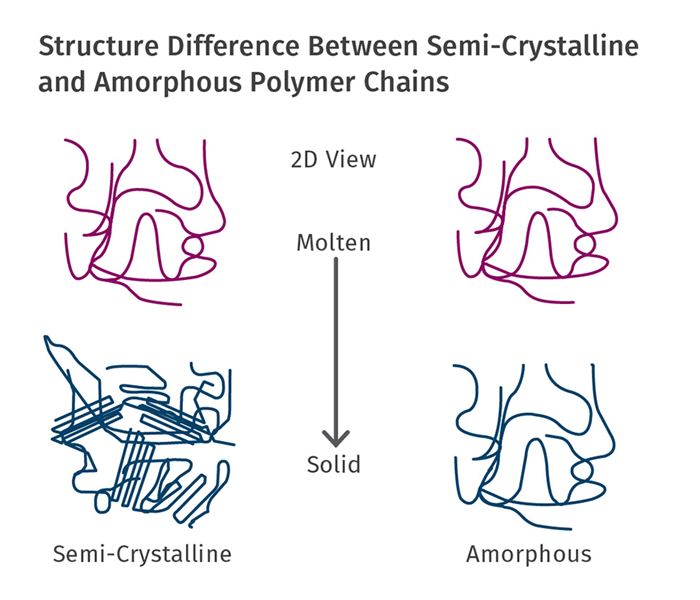

Normally, the differences relate to the different arrangement of the polymer chains in a part. With amorphous polymers, the chains are random—meaning they have no specific order or alignment, something like tangled pieces of string. Semi-crystalline polymers have a structure or ordered pattern of chain alignment.

If you want consistent dimensions and performance 24/7, you must have melt uniformity.

The prefix “semi” is used to note that not all the polymer chains in a semi-crystalline part are crystallized. There are areas of crystallinity and areas of random (amorphous) chain orientation within a given part. Colors, additives, and cooling rate influence the degree of crystallinity, which changes part size and properties.

Regardless of whether the polymer you are processing is semi-crystalline or amorphous, melt uniformity is required to obtain consistent part dimensions and performance. Understanding how each melts allows the processor better control in processing.

Whether semi-crystalline or amorphous, each relies on the same sources of energy for melting: the barrel, screw, and heater bands. Most of the energy, about 80%, comes from friction of the pellets against the barrel wall and compression in the transition zone of the screw. The remainder comes from the heater bands around the barrel. The energy-transfer mechanism is the same for both amorphous and semi-crystalline resins. However, this is where the similarity in melting these plastics ends.

Like ice, semicrystalline resins do not soften until they reach their melting temperature.

An important factor that differentiates them is the amount of energy required to melt each. A kilogram of a semi-crystalline resin, such as nylon 6, requires significantly more energy than 1 kg of an amorphous resin such as ABS. In fact, nylon takes about twice as much energy to melt as an ABS (about 716 BTU/kg vs. 342), yet their processing temperatures are similar. Twice the energy requirement for the nylon means your processing ducks had better be in a row.

So now we know what we must do to melt nylon vs. ABS from an energy standpoint. But there is another issue to make your processing life harder. Semi-crystalline resins stay hard until they reach their melting temperature. It’s like melting ice. Ice does not change in hardness significantly as it warms up from -10 C (14 F) to -0.5 C (31 F). Fall on ice at either temperature and I doubt you will feel any difference in hardness. Like ice, semi-crystalline resins do not soften until they reach their melting temperature. They stay hard until they meet two criteria:

First, you put in enough energy to bring them to their melting point; and second, you have to put in another dose of energy to overcome the heat of fusion (melting)—that is, break up their ordered chain pattern. It is like an energy barrier to melting. How does the screw and barrel handle this difficult situation? The semi-crystalline pellets flow from the hopper into the feed throat and fall between the deep flights of the feed section of the screw. The feed section augers the pellets forward and compacts them, forcing air and some volatiles out the hopper (it is a vent). The feed section may warm the pellets, but it does not and should not do any melting.

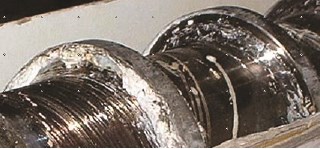

The material then reaches the transition or melting zone, where the root diameter of the screw tapers thicker to provide compression of the pellets against the barrel wall. This compression, along with friction of the pellet against the barrel wall, drives energy into the pellets to raise their temperature. The problem is that not all granules get to the barrel-wall/flight interface—some get the energy needed to melt and some do not. Solid-bed breakup occurs, which leads to some partially unmelted pellets getting through the transition and metering zones. These partially unmelted pellets can wind up in the part and wear the screw.

Amorphous resins melt like frozen butter.

For the sake of discussion, let’s say you are also running liquid color and using a general-purpose screw design. Liquid color often uses an oil carrier, which lowers the friction of the pellet against the barrel, which in turn reduces the energy transfer for melting. Is this really something you want to happen? Turn off the liquid color; does the screw rotation time decrease? A general-purpose screw with a 20: 1 L/D ratio has only five flights in the transition zone. This is a significant problem with shot sizes larger than about 40% of the shot capacity. It’s often recommended that barrier screws be used instead, but they often cause degradation, producing excessive black specks. You’re better off with a screw designed to provide melt uniformity.

Amorphous resins melt differently. They require substantially less energy and are easier to melt. They melt like frozen butter. An amorphous pellet at room temperature is hard, but as it warms up it begins to soften. With more energy, amorphous materials continue to soften until they are suitable for molding. They do not stay hard until they reach the melting point, and they do not have to overcome the heat of fusion. A partially unmelted pellet may be like taffy or a marshmallow. If it gets wedged between a screw flight and the barrel wall, it will squash without severe damage or wear to the screw or barrel. Amorphous resins thus are more forgiving during the melting process. A general-purpose screw may provide acceptable processing, but again, that’s not my recommendation.

In a nutshell, semi-crystalline pellets are more difficult to melt uniformly than amorphous pellets. A general-purpose screw might process amorphous pellets, but with shot sizes at the small end (below 20% of barrel capacity), and at the high end (above 40%), most molders will have problems with semi-crystalline pellets. I don’t recommend barrier designs. Instead, specify a screw design that provides melt uniformity with a minimum L/D ratio of 20:1, though 24:1 is preferred.

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com; scientificmolding.com.

Related Content

Five Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreBozzelli’s Guide To Specifying a Dryer

Here's a list of 17 things to do when looking for new drying equipment.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.jpg;width=70;height=70;mode=crop)