INJECTION MOLDING: Properly Placing & Cooling Insulator Plates

Thermal-energy management from the mold to the platens is critical for making consistent parts.

As injection molding continues to evolve, more applications require polymers that meet high temperature and performance requirements. Often these materials require processing temperatures above 315 C (600 F) and mold temperatures more than 100 C (212 F). These polymers have numerous special requirements in processing, such as high melt viscosities that require 25,000 to 40,000 psi to fill parts, special drying requirements, and strict cooling regimens.

Here, I’ll focus on the problem of keeping the mold at the correct processing temperature without too much heat transfer to the platens of the molding machine. While this may seem like a minor issue in the scope of forming a plastic part, it does have significant impact on part tolerances, consistency, quality, and performance.

In processing these high-melt- and mold-temperature polymers, it is common to see that some problem develops after an hour or more of running production. Most processors understand that with a mold running at 175 C (~350 F) there is an issue of heat transfer to the platens. The greater the difference in temperature between two pieces of steel, the faster the rate of heat transfer.

To mitigate this, molders often place an insulator board or plate between the mold clamping plate and the platen. The insulator plate does help but it still has a thermal conductivity (K factor) of 2.1 Btu/hr/ft2/oF at 220 C (425 F). Heat transfer still occurs, but it takes more time. Platens often get so hot you cannot touch them or work on the mold. If we understand that the platens do indeed get hot and that they rarely have cooling lines, we can begin to see how and why problems develop.

Here’s a short list of the problems due to platen warming: As platens heat up, they expand. If the coefficient of thermal expansion for steel is ~1.1 x 10-5 in./in./oC or ~6.6 x 10-6 in./in./oF, and we have a platen that is 3 ft wide with a 75 F to 275 F temperature change, we have roughly a 0.0475-in. (1.2-mm) expansion. This can spread the tiebars farther apart, like a “Y”, which is likely to present resistance as the mold closes. This shows up as a mold-protection alarm on the machine.

Have you ever seen a clean parting line but the mold will not close after an hour or two of production on one of your hot molds? As the platens warm up they change in size and if they do not expand evenly, you can get wear on the parting line, the platen itself, and the mold—and don’t forget the tiebars.

You also have to think about how long it takes to achieve thermal equilibrium for a stable mold and process. Lots of time and money are lost as the process changes, and what was at one point a good process now produces bad parts.

The point is that heat transfer to the platens is an issue. Is there a better solution than just using insulator plates?

John Klees, a well-respected mold designer, suggests putting insulator plates between the mold and the clamping plate. Then gun drill the clamping plates for cooling and run 65°C (150°F) water through them to protect the platen, mold, and machine (see accompanying illustration).

Here are some benefits of this approach:

• Elimination of excessive heat transfer to the platens.

• Faster time to thermal equilibrium for mold, platens, and tiebars.

• Less wear and tear on the machine and mold.

• Platens will be warm but they can be worked on without burning your hands.

• Far less wait time before you can remove and handle the hot mold.

• Fewer wasted startup shots before you make consistent parts.

• A more stable process.

• Less waste of an expensive resin.

In short, for consistent processing and parts, thermal-energy management from the mold to the platens is critical. In my book, any mold running above 80°C (180°F) needs insulator plates between the mold and the clamping plates and the clamping plates should be water cooled. Also, ditch the hot-oil mold-temperature controllers and use the safer high-pressure water versions. The costs are well worth the benefits.

ABOUT THE AUTHOR: BOZZELLI

John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. E-mail john@scientificmolding.com or visit scientificmolding.com.

Related Content

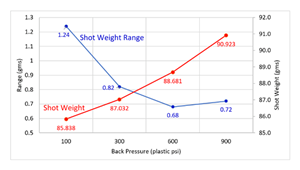

How Backpressure Optimization Affects Melt Preparation

Backpressure is often the least understood of the settings in an injection molding process, even though it can play a significant role in the final quality of the part. Let’s start with understanding what backpressure is and then learn how to optimize it for a given mold.

Read MoreRevisiting the '5 M's' of Molding

All injection molding ultimately comes down to the “Man, Mold, Machine, Material and Method.” But those key aspects can be viewed differently if you’re auditing mold changes before startup or troubleshooting changes for an already validated process.

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreHome In on These Six Variables to Monitor Molding

There are hundreds of variables in molding, but focusing on these six will help you make consistent parts.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

.jpg;width=70;height=70;mode=crop)