Injection Press Converts to Injection-Blow

A simple way for injection molders to get into blow molding of small containers for food, beverage, cosmetic, and pharmaceutical applications has been introduced through a collaboration of Engel Austria, the injection machine supplier (U.S. office in York, Pa.,) and Italian injection moldmaker Cantoni S.r.l.

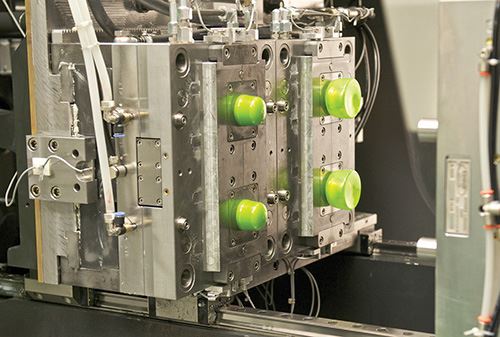

A simple way for injection molders to get into blow molding of small containers for food, beverage, cosmetic, and pharmaceutical applications has been introduced through a collaboration of Engel Austria, the injection machine supplier (U.S. office in York, Pa.,) and Italian injection moldmaker Cantoni S.r.l.. The “inject2blow” system uses an Engel tiebarless machine—either a victory hydraulic or e-victory hybrid model—together with a Cantoni sliding-plate mold and an Engel viper linear robot to demold the parts.

The sliding mold injects two preforms in the center section and then slides alternately to the left or right to blow the parts, while fresh preforms are being injected. Bi-orientation (stretching) option is available. A two-cavity demonstration system can produce wide-mouth jars in a 2+2 cavity mold with a cycle time under 14 sec. The system uses much less floorspace than a conventional rotary injection-blow system. Also, since the system is operated by the Engel CC 200 machine controller, injection molding operators reportedly don’t have to learn a new process. They will simply be guided through the integrated injection and blow molding steps by the familiar Engel controller.

Related Content

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

Flexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

-

Measuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.