Innovations in Molding, Machine Texturing, Micro-Fluidics and More at Canon Virginia Booth

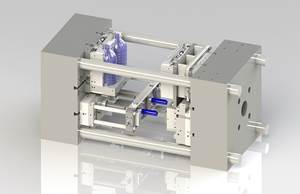

Multi-Mold System shuttles molds in and out to run two separate tools in one press simultaneously.

Canon Virginia Inc., located in Booth W223, has brought the wow factor to NPE2018 this week, showcasing not only its custom mold-manufacturing capabilities and signature vision systems, but introducing a new, sleek multi-mold system, new machine texturing technology and a new focus on medical contract manufacturing.

Takashi Arai, vice president, Advanced Manufacturing Technology Group at Canon, emphasizes the company’s continual pursuit of innovation to provide customers with new and better ways to achieve efficiency in cycle time, mold changeovers and overall productivity.

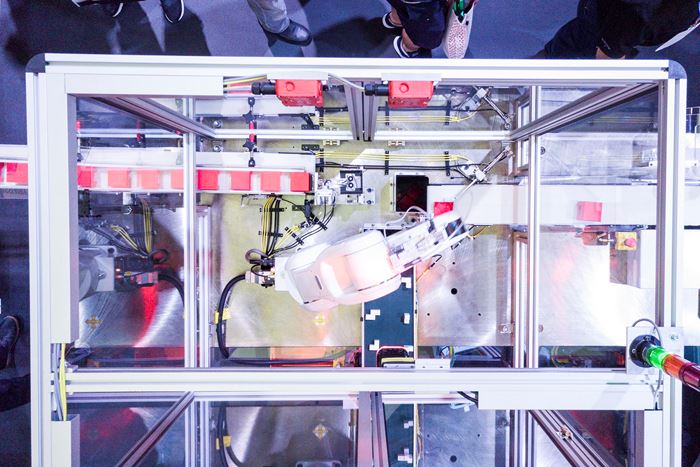

An example is the new Multi-Mold System, which runs two separate molds in one press simultaneously. NPE attendees can see the system in action as it will be running in a customized Sumitomo (SHI) Demag press in Canon’s booth. This is how it works: Plastic material is injected into the first mold. The system then moves the first mold outside the machine chamber for cooling and moves the second mold in place for processing. Then the first mold returns in the machine and ejects its parts, while the second mold moves outside of the machine for part cooling. In addition, the retrieval robot can handle two types of parts with different shapes in cooperation with the system.

This “mold shuttling” process repeats for the next cycle and so on. According to Arai, this system helps transform idle cooling time into productive time by shuttling a second mold into production. The user can program changing conditions like pressure, temperature, injection speed and clamp force as specified for each mold and the system controls the parameters automatically as the mold shuttles back and forth. The proprietary process accomplishes dual, multi-product molding by the same machine without error or loss of time, achieving reductions in cost, time and waste.

Canon entered the medical contract manufacturing arena last year and is giving medical customers a taste of its custom manufacturing capabilities, including precision moldmaking for the medical industry. Attendees can see, up close, as another Sumitomo press demonstrates injection molding of a microfluidic product.

As if that were not enough, Canon is also spotlighting proprietary technology with the introduction of machine texturing for molds that can replace traditional chemical processes. Arai says that with some proprietary vision technology, Canon machine texturing can reduce lead times compared to chemical processes, plus improve mold life and reduce downtime and costs. “This next-generation technology creates product textures that the human eye perceives not as flat surfaces, but as patterns with tactical differentiations based on human sensory response. It creates very precise patterns with delicate features unlike chemical processes that can have wide deviations in texturing,” he says.

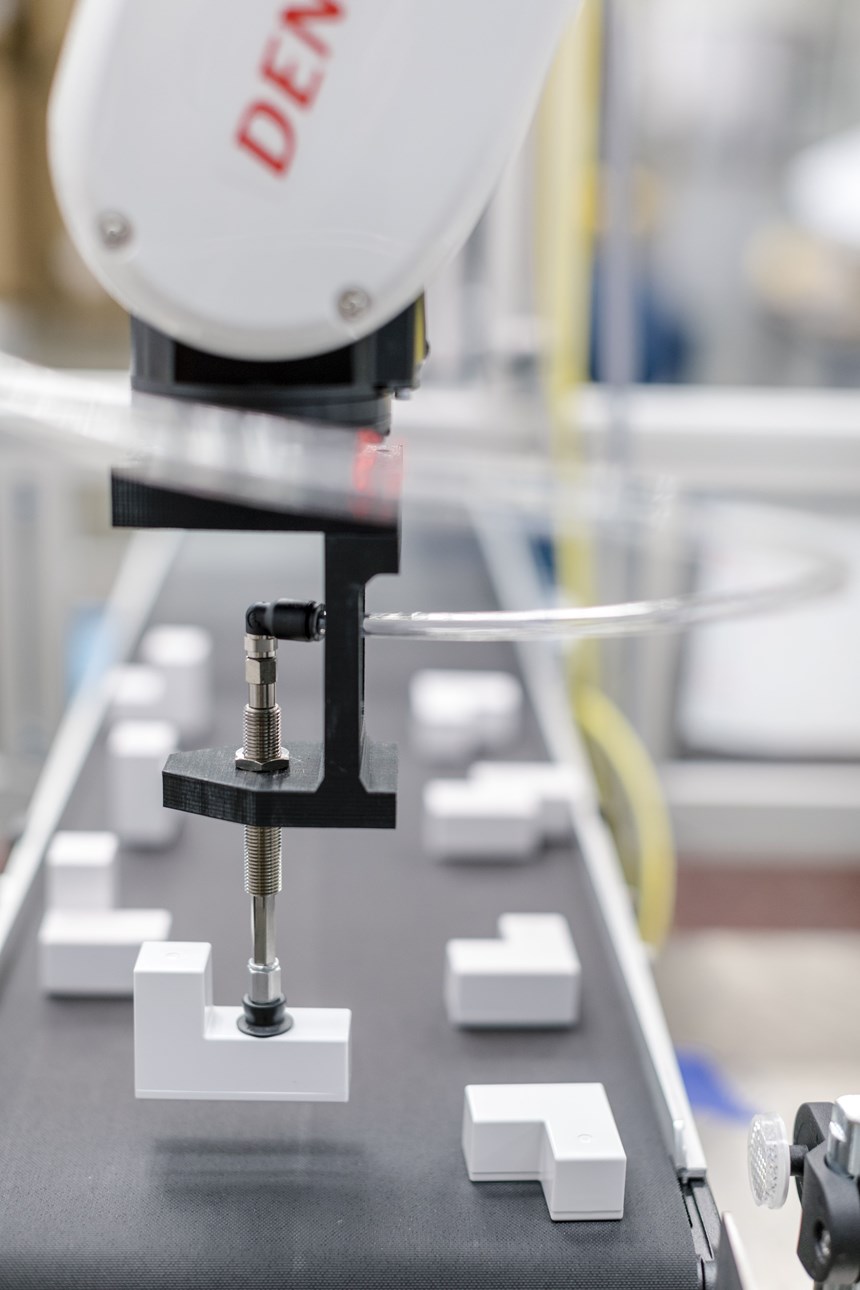

Finally, Canon has a lot of machine-vision systems on display, including 3D vision. Watch as the “eye” utilizes cutting-edge optics, image recognition and data processing to achieve three-dimensional recognition of production parts that are randomly piled in a bin and then snaps multiple images to quickly create a 3D image of the part.

Molds are running parts to demonstrate Canon’s mold-manufacturing capabilities, with parts automatically assembled into a box using robotic arms and handed out to attendees to take home.

Related Content

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreAt NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreAI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More