The profile extrusion process has many variables that processors try to control, and one of the most overlooked is how heat is applied to the profile die via heat transfer from the heater band. Often, a profile cannot be extruded to the same tolerance as the previous run. In response, work is done to the die to compensate for heat not being appropriately applied, or not applied in the same manner as when the tool was hung on the extruder.

Here’s a more efficient approach to that problem. There are five principles of heat transfer processors need to know before proceeding to tooling work.

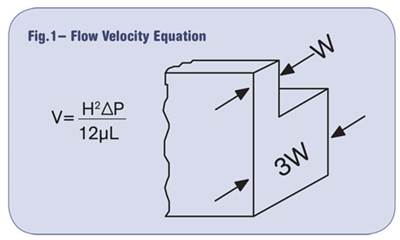

1. Contact: Heater bands tend to curl up away from the tooling after repeated use. Regardless of the heater system or style the processor uses to keep the heater in contact with the tool, an air pocket will develop at some point along the heater band (see Fig. 1). This air pocket will cause the tool to be nonuniform in temperature. The colder tool surface will slow the velocity of the plastic as it goes through this portion of the tool, causing the profile to run out of tolerance compared to the previous run. A gap as narrow as 0.015 in. is enough to cause a temperature variation in that area of the tool.

FIG 1 At some point an air pocket (shown in red) will develop along the heater band after repeated use. This air pocket will cause the tool to be nonuniform in temperature. (All illustrations: T. Groth)

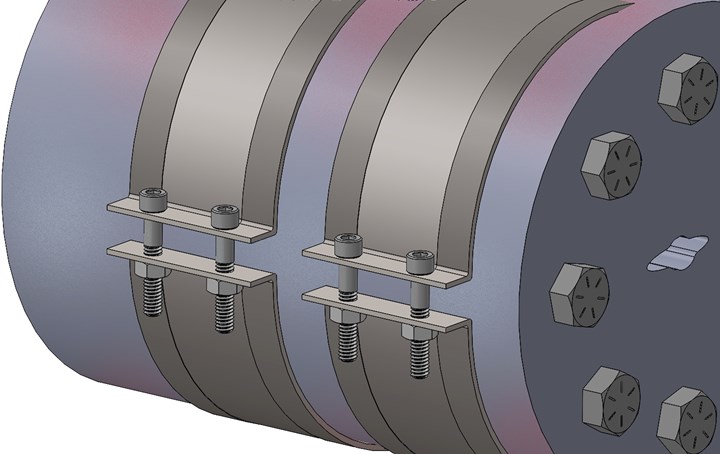

2. Openings: When more than one heater band is used on the tool, the openings need to be rotated 180° to each other. If the openings are parallel, a cold section will develop on the tool, again causing the material to run at an inconsistent velocity. In Fig. 2 the openings are in parallel, and the side of the tool with those openings will be colder than the other side. When multiple bands are required, mount every other band with the opening on the opposite side of the tool.

FIG 2 When more than one heater band is used on the tool, the openings need to be rotated 180° to each other. If the openings are located in parallel as shown above, a cold section will develop on the tool, causing the material to run at an inconsistent velocity.

3. Heater Band Style: There are many styles of heater bands. The scope of this article is not to ascertain what style is best but rather to make processors aware that not all styles apply heat equally to the tool. All bands have an opening in which no heat is applied. The heating distance from the opening on the band varies with band style and manufacturer. The band style with a clamp requiring no tools to tighten tends to have a larger area where no heat is applied (Fig. 3). Be aware of the dead space on the band being used.

FIG 3 Band-style heaters have an opening in the back where no heat is applied.

4. Wattage: Most processors tend to overshoot the wattage required in an effort to speed up the changeover process. Plan for 0.035 kw × in.2 as a standard. Too high a wattage will overshoot the heat required. Temperature controllers must be auto-tuned to the band wattage. If multiple sizes of bands are used on any one extruder tool, standardize by making a ring to cover the tooling and use one standard size and wattage of band.

Heater bands tend to curl up away from the tooling after repeated use.

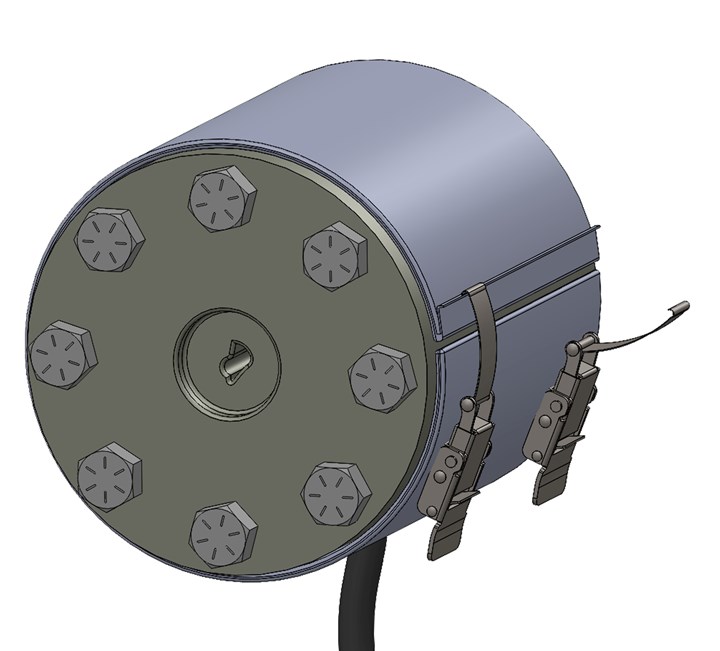

5. Location: The band’s location on the tooling must be duplicated each time the band is taken off. Ideally, the band opening and position on the die will always be the same to repeat the melt temperature across the extrudate. Use some form of locating system on the die as a stop to how far on the tool the band should go on. Also incorporate some form of location for the opening of the band. When the band’s location is changed, the temperature changes, causing a shift in material flow. The velocity of the material will flow toward the path of least resistance, the hottest portion of the tool.

If the position of a heater band and its opening changes, the temperature in that portion of the die changes, causing a shift in material flow. (Photo: Matthew Naitove)

Before starting up the extruder, map the die heat.

Before starting up the extruder, map the die heat. Using a pyrometer, check the temperature on the final die plate in the four directions: North, East, South, and West. Any variation beyond 2° F will require a recheck of the five heater band principles cited above. Don’t do tooling work until the heat transfer is verified by means of temperature measurement.

ABOUT THE AUTHOR: Tim Groth has more than 37 years of hands-on extrusion experience, specializing in design for extrudability, tooling design, troubleshooting, material selection, plant setup, training of engineers and setup technicians, and practicing Lean Manufacturing principles. He is currently dir. of engineering for consulting company Extrusion Solutions North LLC, Hastings, Minn. Contact: 651-357-0814; timtgroth@gmail.com.

Related Content

Novel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.

Read MoreUpdated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read More'Hybrid' Die Design Eliminates Weld Lines, Cuts Stagnation

NPE2024: Newest extrusion tool retains benefits of previous design and adds features to boost quality.

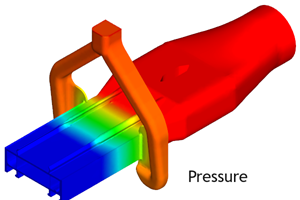

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreRead Next

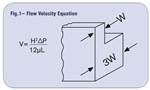

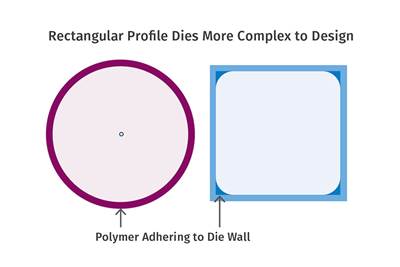

Extrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read MoreTo Troubleshoot Profile Extrusion, First Get to Know All the Variables

It requires patience, logical thinking, and a methodical approach to assess each unique problem and solve the problem in a timely fashion.

Read MoreTooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design—proper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

Read More