K 2007 Injection Molding: Lots of New Machine Choices For Exotic to Everyday Molding

If you were looking for a new machine to mold micro- or mega-sized parts, multiple materials, long fibers, high-speed/high-cavitation packaging, exotic multi-material combinations with compounding on the machine, or just a cost-effective press for general-purpose use—K 2007 had it all.

If you were looking for a new machine to mold micro- or mega-sized parts, multiple materials, long fibers, high-speed/high-cavitation packaging, exotic multi-material combinations with compounding on the machine, or just a cost-effective press for general-purpose use—K 2007 had it all. Eight suppliers of all-electric machines—two of them new entrants—showed off their

latest models or designs. Five makers of hybrid-electrics rolled out new models, and nearly a dozen manufacturers introduced hydraulic machines of every type. Even hydraulic presses have been tweaked for energy savings and lower cost.

ALL-ELECTRICS

In our September K Show preview (see Learn More), we reported on new electric and hybrid presses from Arburg, DPG, Engel, Ferromatik Milacron, KraussMaffei, Netstal, and Negri Bossi. Lots more was unveiled at the show.

Zhafir Plastics Machinery, a German subsidiary of China’s Haitian International Holdings, rolled out its first machines, the Venus all-electric line, designed for thin-wall technical parts in high-end automotive, medical, and telecommunications applications. Haitian International Holdings represents the injection molding business of Ningbo Haitian Group Co., said to be the world’s biggest supplier of injection presses (18,000 sold in 2006). U.S. molders may be acquainted with Haitian Plastics Machinery, which supplies six lines of general-purpose machines.

Ningbo Zhafir, which will be run as a stand-alone unit, will concentrate on electric machines. The new Venus series is said to be an optimization of Haitian’s HTD electric series and uses a number of European components. The double-toggle press is driven by five AC servo motors with belts and ballscrews. The control system from Sigmatek of Germany reportedly provides 0.25-millisec response time. The software also allows users to program for injection-compression molding. The machines come in a range from 44 to 451 tons and are assembled in Germany, although most of the machines will be shipped to Asia. Each press size offers a choice of four injection units with three screws apiece. Zhafir claims 70% energy savings vs. comparable hydraulic machines. Zhafir also is developing a tiebarless all-electric machine called Mercury with two-stage injection and models from 44 to 550 tons.

Meanwhile, Arburg added an Allrounder 520 A model to its all-electric toggle line targeting small and micro-component molding. It comes with clamp forces of 143 or 165 tons, and has enlarged space between tiebars to handle bigger molds. It also uses Arburg’s new small size 70 injection unit with screw diam. of 18, 22, and 25 mm, providing shot sizes up to 40 g. The Allrounder A line now spans 55 to 220 tons.

Battenfeld broadened its EM line of electric machines with a new 330-tonner, which extends the line beyond 198 tons. Battenfeld demonstrated an EM 110/300 at the show, molding LSR baby-bottle nipples in six cavities on a 25-sec cycle.

Billion SAS of France (represented here by Oaktree Consulting), unveiled its first all-electric machines, the Select series from 75 to 150 tons. Each unit has at least six AC servo motors (nine with two injectors for multi-material molding, which is Billion’s specialty). This five-point toggle machine uses ballscrews for ejection and nozzle touch and planetary roller screws for injection and clamping, where higher force and precision are required. At the show, Billion demonstrated two-shot molding with its 110-ton Select Multi H150/260-100T, which made a garage-door opener from glass-filled PBT and TPE in 35 sec.

Demag Plastics Group (DPG) announced previously that it had revamped and expanded its all-electric IntElect series with its new NC5 control and high-torque water-cooled direct drive motors for all main movements. A 385-ton and 462-ton model will be added to the line, which currently ranges from 55 to 230 tons. Lower cost IntElect models made in China will debut this year, starting with a 110-tonner, and later adding models from 27 to 220 tons.

As reported in September, Engel introduced its e-max line, the first all-electric machines that are price-competitive with comparable hydraulic machines.

Fanuc of Japan, represented here by Milacron, exhibited its new Roboshot S-2000iB all-electric series with a new FDA-approved lubricant that substitutes for grease. It has become a prerequisite for use in medical and technical applications. Fanuc demonstrated an automated workcell with a 55-ton machine molding LCP connectors that were demolded by a Fanuc robot and inspected with its iR Vision system for good/bad part separation.

Meanwhile, Sandretto of Italy (distributed here by HPM) plans to roll out an all-electric series at the end of 2008.

Tiny electric presses for micro-molding also made news. MCP Tooling Technologies launched its new 12/90 all-electric model, which has a clamp force of 9.9 tons and shot sizes from 1.6 g down to a few milligrams. It is designed as a clean-room machine and uses a reciprocating screw instead of a plunger.

MCP also introduced its all-electric 12/90 VSA model for insert molding or overmolding. The tiebarless system uses a sliding or rotary table and is suitable for medical molding.

Desma Tec, a subsidiary of Klockner Desma Schumaschinen, a German maker of urethane and rubber machines, rolled out the FormicaPlast micro-injection molder that can make small parts from thermoplastics or metal powders. Developed by the Kunststoffzentrum (KUZ) scientific institute in Leipzig, this servo-electric toggle system features a two-stage screw/plunger system for highly responsive molding and injection speeds up to 500 mm/sec. The 1.1-ton unit molds parts weighing less than 0.28 mg. The Desma-Tec line is sold here by Creative Mold.

NEW HYBRID ENTRIES

Chen Hsong rolled out its Jetmaster Ai electric/hydraulic hybrid series designed for fast cycles and energy savings. The line uses either Bosch Rexroth or Moog servo valves to control the accumulator-assisted hydraulic system, which is said to reduce energy use by 40% compared with a fixed-pump system. They also have a new controller that reportedly enables extremely high-precision movements. Machine response time is from 25 to 60 millisec, depending on type of system selected. Injection rates range from 300 mm/sec for high-speed models to 500 mm/sec for ultra-high-speed operation. The Ai line also uses a patented circular platen design that uniformly distributes stresses for minimal platen deflection. Three models range from 108 to 196 tons. Users can add the new iChen shop-floor networking system, which is now wireless instead of LAN based.

Haitian Plastics Machinery introduced its new hybrid electric machine, dubbed the Mars series. It encompasses 16 models from 66 to 660 tons that replace the former J5 line. They have new controls from Keba of Austria and an AC servo-driven gear-pump system that reportedly achieves 20% to 70% energy savings vs. conventional hydraulic machines.

As noted in our September show preview, Netstal brought out its Evos hybrid toggle concept that will replace its 10-year-old SynErgy hybrid toggle line in the 220- to 500-ton range. The Evos is hydraulic except for its servo-electric screw drive, but all axes of movement are under digital closed-loop control, including the secondary movements. A new clamp design keeps platen deflection the same as in the Synergy models but the moving mass is reduced 35%. This leads to a slightly faster dry-cycle time. Addition of two digitally controlled Moog valves improves response time to 16 millisec from almost 50 millisec on the Synergy.

A 385-tonner produced thin-wall, MuCell-foamed PP containers with in-mold labeling in a 4+4 mold on a 5-sec cycle (110-g shot weight), while a 550-ton unit made closure spouts from LDPE in a 144-cavity mold in 3.75 sec (144-g shot).

As reported in September, DPG has speeded up the clamp on its hybrid El-Exis S series for 10% to 20% faster dry cycle and updated its controller to the new NC5 design with enhanced mold protection.

Sandretto added a 495-ton model to its Nove HPF line of fast cycling hybrid presses for packaging. The largest model had been 396 tons. The line has electric screw drive, with all other motions driven hydraulically. In addition, Sandretto is building a plant in Shanghai and is developing a new Nove HP line that will combine European and Chinese machine concepts.

Husky demonstrated its Hypac hybrid with direct-drive electric injection unit (introduced at NPE 2006) in a lightning-fast in-mold labeling system. A 300-ton unit molded four rectangular PP containers (250-g capacity) with Husky’s Ultra Packaging hot-runner valve gate and Muller IML mold and labeling system in 2.9 sec.

LOTS OF NEW HYDRAULICS

Arburg has extended the size range of its Golden Edition series with three new models. The new 506-ton Allrounder 920 S Golden Edition has 920 x 920 mm tiebar spacing and shot capacity up to 2.8 lb. Arburg also added two vertical rotary-table models to the Golden Edition—the 88-ton Allrounder 1200 T 800 and 110-ton Allrounder 1200 T 1000.

Arburg also merged its smaller Allrounder U line into its larger Allrounder S series and added a new size to create a more comprehensive hydraulic product line. The Allrounder S line now has 10 models from about 15 to 550 tons, including the brand-new 220-ton Allrounder 570 S. Selogica Direct touchscreen controls are available at no extra charge. The fully accumulator-driven presses come with optional electric screw drive.

After shrinking its machinery portfolio last year from 18 to three main product lines (with a fourth to be built as needed), DPG has rolled out a brand-new hydraulic line for general-purpose use. This “Pink” series is based on its Systec hydraulic line but is lower priced due to the fewer available options. It replaces the company’s former Extra series. Sizes range from 38.5 to 462 tons. Models larger than 500 tons will be developed this year.

Pink machines come with DPG’s new NC5 control, an improved oil-management system, and a choice of three screw sizes for each model. Linear guidance of the moving platen and an ultrasonic stroke-measuring system for all movement axes provide precise operation. Servovalve technology reportedly ensures parallel movement of the ejector. The line also has DPG’s activeQ mold-protection software.

DPG also will expand its Systec line with new toggle-clamp sizes from about 450 tons to 800 tons and 1000 to 2000 tons.

Engel added a new 550-ton model to its dual-toggle Speed line for high-speed packaging. It also introduced the IL 3560 inline injection unit, which can be equipped with a barrier screw for high throughput with low material stress.

Presma has developed a new press expressly for coinjection molding. The new GTS200 Bic has two identical injection units, which can inject through the same nozzle simultaneously. It also has a rotary table. At the show, the unit produced a door handle with a foamed PP core and TPE skin.

Sandretto developed its new Mega NH line from 660 to 2200 tons with software features that allow for injection/compression molding. The E1 SEF-2000 software now also allows for wireless remote communication to call for assistance or to order spare parts right from the machine. The controller can also provide details on the machine’s energy consumption relative to its production rate.

TWO-PLATENS PROLIFERATE

Battenfeld now offers its HM two-platen unit in sizes above 715 tons with new 880-, 1100-, and 1430-ton models built in Austria. Battenfeld also announced plans to expand its technical center in Meinerzhagen, Germany, with molding cells for gas and water injection and foam molding.

Chen Hsong’s new Supermaster TP two-platen series of large machines is targeting automotive applications. Seven sizes range from 2420 to 7150 tons, all with the new Ai-11 control. Clamp movements are said to be as fast as 750 mm/sec A patented tiebar hydraulic connection reportedly reduces stress concentrations and simplifies maintenance.

Stork Plastics Machinery, a Dutch press maker with a new U.S. rep, rolled out its new S+ series of accumulator-assisted large machines. The successor to its S series comes in sizes from 110 to 1540 tons and features a new drive system and improved controls. A new Eco Mode function adapts the drive system to the process for energy savings, says Anthony Thompson, the U.S. rep. Users can select a fully hydraulic model or hybrid version with electric screw drive.

KraussMaffei introduced a small two-platen line for general-purpose applications. The ClassiX line is based on KM’s CX series but with fewer options and about 15% lower price and faster shipping (around 20 days from order to delivery). It runs from 38 to 143 tons and comes with hydraulic or electric drive for the screw and ejector. A cantilevered clamp helps to free up floor space and allows access from three sides. A KM65-180CX press was teamed with the firm’s new LRX-S 50 top-mounted linear robot (33-lb payload capacity).

Negri Bossi’s new 1320-ton VH1200 Bi-Power two-platen unit is the smallest in the line, which ranges up to 6600 tons. A new 15-in. control screen is standard.

Boy rolled out its PC-based Procan Alpha control for its line of small two-platen machines. It replaces the 32-bit Procan CT control and features a 15-in. touchscreen, new freely configurable programming page, and a separate hardware module that handles processing of analog signals and frees the PC from all time-critical tasks, which speeds response. An Iterative Learning Controller program helps reduce start-up and set-up times and “learns” to control process deviations in the course of a run.

FOR PET PREFORMS

Chen Hsong unveiled its first 72-cavity Chen-Pet preform molding system. It previously made systems for up to 48 cavities. The new system is driven by a new 450-ton press with hydraulic accumulator, four Moog servo valves, and two 2-axis digital motion controllers for closed-loop speed and pressure control.

Husky unveiled a new HyPET high-performance package for PET preform molding that reportedly trims cycle times of high-cavitation tools by 15%. Refinements were made to the mold, robot, injection unit, clamp, and auxiliary equipment. At the show, a 96-cavity HyPET system molded 12.1-g, 500-ml water-bottle preforms in 5.5 sec, which compares with 6.5 to 7.0 sec with a standard package.

Husky also launched Flex Mold, a low-cavitation preform mold that helps reduce mold conversion costs and mold-change times. Fewer components need to be replaced when changing from one preform type to another. The body of the cavities can be changed while the tapers and gate pad remain in the mold, eliminating the need to cool and then reheat the hot runner. Flex Mold is available with eight cavities for neck finishes up to 63 mm diam. or 16 cavities for necks up to 43 mm.

As reported in September, Netstal launched its smallest size PET-Line model to date, the PET-Line 2000 (220 tons), suitable for 24- to 48-cavity molds.

For details on a new preform injection machine from stretch-blow machinery maker Nissei ASB Co., see p. 66.

FOR CAPS & CLOSURES

Ferromatik Milacron showed the first model in its new Cap-Tec line specially built for cap and closure molding. Its Cap-Tec 300 (330 tons) produced thin-wall closures from a 72-cavity mold at rates projected to be 100,000/hr. Thicker caps for carbonated beverages can be molded at up to 80,000/hr. The line is based on the K-Tec press but is stripped of functions not required for this market in order to reduce cost and raise productivity. It has an electric screw drive and accumulator-assisted hydraulic clamp with a short-stroke design for molding small parts at high speed. Both 220- and 440-tonners are in development.

Husky announced several enhancements to its Hylectric machines designed for production of closures. These include a new high-output screw drive and a new screw design that ensures melt quality and maintains control of melt temperature at high throughput rates. The system was demonstrated with Husky’s new Ultra 350 hot-runner valve gate for improved part quality, tight gate pitch, and throughputs up to 30 g/sec.

NEW PROCESSES

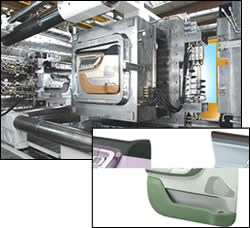

As reported previously, KraussMaffei demonstrated two novel approaches to multi-material overmolding. One was its SkinForm process, which involves injection molding auto parts with a rigid thermoplastic substrate (PC/ABS in this case) and RIM overmolding with a two-component thermoset urethane skin. The other demonstration also involved overmolding a thermoplastic (glass-filled nylon 66) with urethane—only this time, the soft component was a TPU into which was blended a liquid crosslinking agent to achieve the properties of vulcanized rubber. This was the first publicly demonstrated use of KM’s two-stage, twin-screw Injection Molding Compounder (IMC) for a purpose other than mixing long-glass fiber into thermoplastic composites.

Husky demonstrated its In-Line Compounding (ILC) cell for long-glass mixing and molding, which mounts a Coperion twin-screw compounder on a plunger injection machine. Germany-based Brose is using it to mold door-module carriers converted from metal. French-based Faurecia is using the ILC to lightweight door-module carriers for Ford.

At the show, Husky ran a version of its ILC on an 1485-ton Quadloc Tandem press molding long-glass/PP door-module carriers in two standard molds arranged in a stack-type system. The 5.3-lb shot required a 50-sec cycle. Two Fanuc six-axis robots mounted on the tiebars demolded the parts.

Engel has its own brand-new two-color, long-glass injection molding compounder developed with German twin-screw compounding specialist Leistritz Extrusiontechnik GmbH. A 1100-ton Engel Duo two-platen machine is integrated with a Leistritz ZSE Maxx corotating twin-screw extruder. Like the KraussMaffei system, Engel runs the extruder continuously and uses a “melt pot” accumulator for intermediate storage. The system is aimed mainly at automotive, as well as pallets and crates, and it can also process natural fibers.

Engel demonstrated the new Exjection process that produces long thin parts by “intrusion molding,” a combination of injection and extrusion, involving gradual filling of a vertically moving mold cavity. The process was developed by IB Steiner Innovation Business and Hybrid Composite Products GmbH in Germany and has been licensed to both Engel and Arburg.

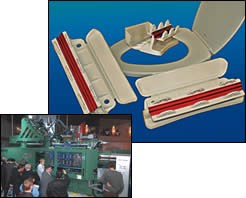

Ferromatik showed a complex multi-component application for the rotating “cube” tooling system from Foboha of Germany. The part was the hinge mounting bracket for the new Xcite toilet seat from Bemis Manufacturing Co., Sheboygan Falls, Wis., one of the largest producers of toilet seats in the world. Bemis specializes in multi-component molding, but this is its first cube system. It molds the brackets from PP and TPE with three living hinges, replacing eight formerly separate parts that required secondary assembly. The bracket is made on a 496-ton K-Tec hydraulic machine with a four-face, 6 x 4 cavity turning stack mold. The center stack turns 90° in 1.5 sec and produces six parts every 20 sec.

Related Content

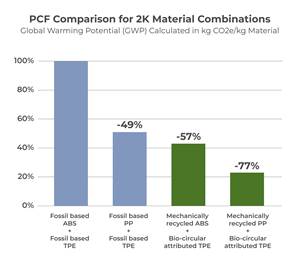

More Sustainable Two-Component Overmolding

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

Read MoreArburg Open House Emphasizes Turnkey Capabilities

Held at the company’s U.S. headquarters in Rocky Hill, Connecticut, the event featured seven exhibits, including systems that were designed, sourced and built in the U.S.

Read MoreTederic Promotes High Technology, Broader Market Presence

Four cells are running in its booth including a 1,300-ton multimaterial system highlighting its 2K capabilities.

Read MoreVideo: Ultradent Bags Both Hot Shots Prizes at PTXPO 2023

Topping five other entries in voting by fellow molders, the Ultradent team talks about their Hot Shots sweep.

Read MoreRead Next

What's New at the Show in INJECTION MOLDING

At the big “K” Show next month, top billing goes to new all-electric machines aimed at every segment of the market, from general-purpose to high-end.

Read MoreNew Injection Machines and Processes To Debut at K 2007

A brand-new line of all-electric machines priced on par with comparable hydraulic presses and the first public demonstration of insert molding RFID chips into plastic parts will be two highlights of the Engel display at the mammoth K 2007 show in Dusseldorf, Germany, this October.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More