Keep Machines Running in Top Form With New Software ‘Wizards'

Help has arrived for overworked plant managers, process technicians, and maintenance personnel. It comes in the form of three new Windows-based "Smart Manufacturing" software modules from Hunkar Laboratories, Inc. in Cincinnati. Hunkar's Smart Manufacturing philosophy is based on the principle of pre-emptive problem solving, which translates into "Fix it before it's broke."

According to Hunkar president Rick Thiemann, this philosophy addresses trends in the marketplace. "Continuing mergers of processing companies puts more and more responsibility on the shoulders of fewer and fewer knowledgeable people. Where they used to watch over several machines, now they're watching several plants." At the same time, he says, "Molders' customers have lost their sense of humor. And they've lost their loyalty. They won't tolerate a vendor that ships them any bad parts." Hiring armies of QC inspectors is not the answer, Thiemann explains. "That's too expensive, and once you have spent the time and money to make a bad part, it's already too late."

Thiemann's answer is, "You must rely on your maintenance team to run the plant." He broadens the definition of maintenance to include a hybrid of traditional maintenance people who know how machines work and technicians who know how to maintain a process. Notes Dale Lucas, Hunkar's director of business development & training, "I see more and more maintenance people coming to process-development classes. They feel that the more they know about the process, the faster they can fix the machine to give the desired result."

Plant watchdog

New Smart Maintenance Wizard is an add-on software module for Hunkar's Source CIM system. Costing about $5000, it schedules maintenance for both injection machines and molds. It automatically notifies users of tasks, defines all work to be done, reports the date completed, compares projected vs. actual time to completion, and documents the material cost and labor rate. Another report summarizes work orders by category—scheduled, unscheduled, preventive, breakdown, major repair, safety-related, or project-related. Machine maintenance can be scheduled by operating hours or number of cycles. Tool maintenance is scheduled by cycle count, and an automatic warning can be programmed to alert the user when there are a certain number of cycles to go before the next scheduled maintenance. The software continuously tallies how many hours and/or cycles it has been since the last maintenance of the machine or mold, plus the total operating hours or cycles for the year to date.

The unique aspect of Smart Maintenance Wizard is that it treats maintenance not just as a set of scheduled tasks but as an activity directed toward a goal, which is optimum machine performance. The Wizard analyzes "current machine capability," which is the ability of the machine to maintain each parameter monitored within a statistical deviation band above and below the mean. A quick yardstick for objectively measuring machine capability is Hunkar's Class Factor system, a nine-level scale in which Class 1 indicates the tightest and Class 9 the loosest degree of control. The Wizard applies a Class Factor to each parameter monitored and the poorest Class Factor number is the Class for the machine as a whole.

The Wizard helps identify "troublemakers" among the machines in your plant by displaying a pie chart for each press showing the relative amounts of uptime, downtime, repair time, and idle time. If you place the cursor on a section of the pie, the screen shows the cumulative hours and percent of machine total available hours for that category.

Hunkar interprets the goal of machine maintenance as maintaining the Class Factor(s) at the best value the machine can achieve. Smart Maintenance Wizard reports the Class Factor history of each press so that maintenance workers and other managers can tell if machine performance is degrading, which would ultimately threaten part quality, productivity, or both. In this manner, the Wizard also provides a benchmark of effectiveness of the maintenance department.

Likewise, tool work orders show the Class Factors of machines on which the tool has produced good parts, and the software will warn you if you try to schedule the mold for a machine with a lower Class Factor. Instead, the Wizard will suggest a "capable" machine to run that tool. The latest modifications of the Wizard also take into account platen size and core and ejector configuration to recommend an appropriate press for a mold.

Watch for process drift

Another new module for the Source CIM system is the Process Wizard ($7000). It automatically and continuously evaluates the capability of all your plant processes including auxiliary equipment and secondary processes like decorating or assembly. "Your maintenance people can't afford to respond to alarms," says Thiemann. "They must be alerted to process drift before the machine makes bad parts."

Process Wizard continually recalculates Class Factors for every monitored process parameter, and then alerts the responsible personnel if any Class Factor deteriorates while the machine is running. In most cases, Thiemann says, such notice gives a window of 8 to 20 minutes in which to address the problem before any bad parts are produced.

Although such pre-emptive alerts are helpful, Thiemann says, "No one wants to waste time on diagnostics to find out what is going wrong. They want solutions right now." Process Wizard creates an on-screen equivalent of yellow Post-It notes that say, "Machine 16: Process is degrading" and offers a solution such as "Check Hold Pressure" or "Check Plasticating Time." If more than one action is recommended, they will be listed in order of priority by importance to product quality. These alerts can be broadcast by Hunkar's new Smart Beeper system to pagers worn by relevant personnel. The pager system, which is said to be immune to plant electronic "noise," displays the entire text of the yellow note.

A basic ‘starter kit'

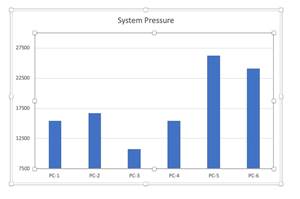

For molders that don't have a Source CIM system, Hunkar introduced a low-cost, stand-alone "process-degradation detection system" called Rev-a-lee. It uses the Smart Beeper to send notes to pagers when Class Factors degrade. This simplified version of Process Wizard runs constantly in the background on a PC. It monitors seven Class Factors per machine and has only seven PC display screens. They include a pie chart of the type and number of alerts broadcast per machine and bar charts comparing the total number of alerts and the overall Class Factor for each press. Another bar chart compares Class Factors for each press during different work shifts.

A $25,000 package for 10 machines includes software, 10 machine-interface units, two pagers, one Smart transmitter, and one day's installation and training. Payback in three months or less is typical, Hunkar says.

Related Content

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More