Success in LSR Molding

Liquid silicone rubber parts are getting larger, but most LSR molders still have relatively small injection machines with limited shot capacity.

Liquid silicone rubber parts are getting larger, but most LSR molders still have relatively small injection machines with limited shot capacity. Custom molder Limtech Inc. in Sturtevant, Wis., faced that challenge a year ago when it tried to injection mold a large LSR part on an undersized press. After some trial and error, Limtech developed a new process capability that could benefit other LSR molders in similar circumstances.

Limtech specializes in LSR molding and has 25 presses of up to 88 tons from Boy Machines Inc., Exton, Pa. When asked to mold a 12 x 22 in. “finger” mat used inside sterilization trays for medical instruments, the part looked initially like more than they could handle. “We realized that the 1.2 lb of material required for the part exceeded the 8-oz shot capacity of the largest injection press in the shop,” says Bob Albrecht, general manager and v.p. of operations. “But we also knew the mold would physically fit one of our 88-ton Boys.”

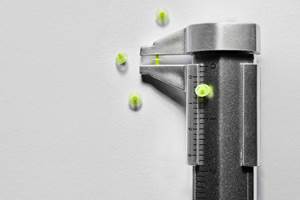

How to mold a 1.2-lb part on an 8-oz press: Limtech found the old technique of intrusion molding is handy for larger LSR applications like these finger mats.

Limtech found the answer in an old technique that may be unfamiliar to many injection molders today. Limtech is now running 25,000 finger mats a year in a single-cavity operation. In fact, Limtech says it can injection mold the finger mats at lower cost per part than is possible with the transfer molding process usually used.

What’s old is new again

At the heart of Limtech’s new process capability is an old technique called intrusion molding, which is offered as a standard programming feature on Boy machines with the Procan CT control. “The capability has been around for a long time,” says Anthony DiBattista, process technician at Boy. It allows an operator to exceed the rated maximum shot capacity of an injection press. After the mold locks up, the injection nozzle is opened, and the screw rotates without moving forward. “The screw is used as an extruder prior to its use in injection as a ram,” says Albrecht. The injection function carries out the final filling and packing steps.

Here is where Limtech’s years of LSR molding know-how proved vital. Using intrusion means that a portion of the material for the part will enter the mold under low speed and pressure (under 100 psi), while the remaining portion of material is injected into the mold under high speed and pressure. “How to fill the mold completely before the extruded material sets up, and how to prevent flow lines between the extruded and injected material, are some of the keys to using intrusion to gain a molding advantage,” says Albrecht. Intrusion also means operating with full screw flights in order to control shot volume, something injection molders may not be accustomed to. Intrusion does extend cycle times—however, it compensates economically by allowing use of undersized presses.

Limtech has been molding LSR for almost a decade, but this case demonstrates that there are still new tricks to be learned. “LSR is always tricky to process. There are batch-to-batch variations that require very close monitoring and frequent adjustments along the way,” says Albrecht.

Related Content

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreUpdated Control, Cooling Water Distribution, Electromechanical Ejector and Injection

NPE2024: Boy’s U.S. subsidiary marks its 50th anniversary in Orlando with six machines and U.S. intros for the Procan ALPHA 6 control, and hybrid ejectors and injection units.

Read MoreAll-Electric IMM Advances for Packaging, Medical and LSR

NPE2024: Sumitomo SHI Demag’s show focus is on the application of all-electric injection molding machine technology for a variety of markets and components.

Read MoreSlimmer All-Electric Press Debuts

NPE2024: A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More