Long-Glass Leader-How Faurecia Helped Put TP Composites In the Driver's Seat

Europe's third largest automotive molder, Faurecia, uses five different long-glass thermoplastic molding processes, more than any other molder in the world. It invented half of them, including the world's first in-line compounding- and-injection process.

Over the past 10 years, French automotive molder Faurecia has emerged as a major technology force in reinforced thermoplastics. The firm, newly headquartered in Nanterre, has expanded the range of processes and applications for direct compounding and molding of polypropylene with long-glass fibers. Faurecia's leadership in this field is no accident: Though a young company, it has plenty of history in long-fiber thermoplastics (LFT).

Faurecia (which has a U.S. operation, Faurecia Interior Systems, in Farmington Hills, Mich.) was formed three years ago from the merger of three automotive molders. The acquirer was E.C.I.A., a Peugeot company that compression molds car seating systems and structural parts like front ends and bumper beams. E.C.I.A. had a long history of innovation and a sheaf of important LFT patents to prove it. Among its accomplishments, E.C.I.A. was the pioneer of direct in-line compounding and molding of LFT (DLFT) with an injection machine.

Its DLFT R&D work in the mid-1990s was part of a bigger European movement driven by a handful of car makers like Peugeot, Mercedes Benz, Volkswagen, Audi, and G.M.'s Opel. All wanted to find ways to replace costly glass-mat thermoplastic (GMT) compression molding with DLFT.

"We'd been trying for 10 years to get away from GMT," says Philippe Dumazet, Faurecia's process and material portfolio manager of R&D for interior systems and holder of some of E.C.I.A.'s early patents. E.C.I.A. had compression molded GMT since 1985, and Faurecia still molds GMT front ends and bumper beams today. Though GMT offers high strength, DLFT's big advantages are material and labor savings plus greater flexibility in part design.

DLFT spurs competition

In 1998, E.C.I.A. bought Bertrand Faure, a French producer of seat modules, and became Faurecia the same year. Faurecia then had big plans to expand into molding car interior parts. By 2000, Faurecia had acquired Sommer Allibert, a large French custom injection molder of interior modules, including carpets, floors, and trunks. Sommer Allibert also did a small amount of non-automotive compression molding.

The newly combined company now had the size, depth of injection molding skills, and market access to guide the development of DLFT into injection molding.

But several European automotive molders were ahead of the new player in the DLFT race. In 1996, Johnson Controls Inc. in Grefrath, Germany, got the order for the first commercial automotive DLFT compression molding job—to make instrument-panel carriers for the Mercedes C Class car. Johnson Controls started production two years later in 1998, using its own DLFT compression molding process, called Fibropress.

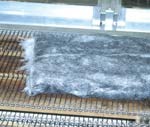

Fibropress starts with powdered PP homopolymer and 5-mm-long chopped glass, which are gravimetrically fed into a reciprocating single-screw extruder. The screw extrudes a strip of compound, which is cut and placed by a robot into a compression mold.

Back then, Faurecia received the I.P. carriers from Johnson Controls and overmolded them with foam and skin for Mercedes-Benz. When Johnson Controls got the initial order, R&D speeded up at Faurecia. "It was a big motivation for us to accelerate our own DLFT processes," recalls a Faurecia development engineer.

By the time Johnson Controls started Fibropress production of the I.P. carriers for the Mercedes C Class in 1998, Faurecia also had successfully commercialized its first DLFT compression molded part, a front end carrier for the Peugeot 206 car.

First injected DLFT

Two years later, in June 2000, Faurecia started up what is believed to be the first injection molding process for DLFT. Faurecia calls it "XRI" (glass roving injection). The first production part was a front-end carrier for the Peugeot 307 car, introduced in late 2000. By March 2001, Faurecia was molding 2000 parts a day with XRI.

Faurecia's XRI process is a hybrid of continuous twin-screw compounding with discontinuous injection molding. In fact, the compounding extruder and molding clamp section are separate machines, 6 ft apart. First, continuous glass rovings are fed directly into the barrel of a twin-screw extruder at a point midway down the barrel where it meets molten PP. The screw both chops the glass and mixes it with resin. Molten compound is then transferred from the extruder to the mold by a big Motoman five-axis, jointed-arm robot.

The robot manipulates a big syringe-like cylinder, which holds roughly 13 lb of compound. The robot positions the hydraulically powered cylinder to draw glass-filled compound out of a container that continuously receives hot melt from the extruder.

When the syringe cylinder is full, the robot pivots 180° and positions the cylinder nozzle over a hole on top of the first of two heated "shooting pots." Then the robot moves to fill the second shooting pot. When both shooting pots are full, two plungers push the compound simultaneously into the two mold cavities. By then, the robot has swung back with the empty syringe to collect a new load of DLFT compound.

Transferring resin by syringe is cumbersome, but it has the advantage of moving a fragile extrudate very gently to protect the glass fibers. It also protects the hot resin from contact with oxygen in the air. On the unloading side of the press, two more five-axis Motoman robots remove molded parts and place inserts into each cavity, where they are held magnetically.

After the first XRI line went into production, Faurecia turned to injection press builder Krauss-Maffei to develop a more integrated and compact machine that wouldn't need robots to get the melt to the mold. A prototype of Krauss-Maffei's solution was shown at K'2001 in Dusseldorf last year. It has a twin-screw extruder mounted on a two-stage injection machine. The continuously running extruder fills an accumulator, which feeds a plunger injection cylinder.

Krauss-Maffei has delivered three XRI lines to Faurecia—the latest one just last month. They are making mostly front-end carriers for cars such as the Citroen C3.

Getting away from GMT

In 1998, Faurecia had commercialized its first in-house DLFT process for compression molding, which it calls XRE (glass roving extrusion-compounding). It uses 60% PP and 40% long-glass roving. The compounding step is the same as for XRI. The difference is mainly in the transfer of hot compound to a compression instead of injection mold. Since 1998, Faurecia has used the XRE process in its Audincourt, France, plant to make front-end carriers for the Peugeot 206.

Dieffenbacher GmbH in Eppingen, Germany, developed a second DLFT compression process for I.P. carriers with Sommer Allibert at its Worth-am-Rhein, Germany, plant before its acquisition by Faurecia. In Dieffenbacher's process, glass-fiber integrity is protected to a greater extent by separating the PP melting step from the glass-incorporation step. PP is melted and mixed with additives in a twin-screw extruder. Meanwhile, glass roving comes off 36 or 48 spools arranged on four or five pallets. Fiber content is controlled by loss-in-weight mechanisms on the platforms. Roving is pulled through a stack of five heated rollers, each one hotter than the last, until the fiber reaches 428 F before it goes into a second, shorter twin-screw cutting and dispersing extruder. As the rovings enter, a film die coats them with melt from the first extruder. A special screw element cuts the fiber into uniform lengths of 17 to 70 mm.

The DLFT compound is extruded as continuous "cake," then cut by a guillotine cutter, gripped by a robot, and placed in an 1800-ton Dieffenbacher compression press. Dieffenbacher also developed a new hydraulic nozzle to profile the continuously extruded cake. A second robot removes parts with suction grippers. (For more details, see PT, March '02, p. 37).

Dieffenbacher's next line for Faurecia was installed in Worth-am-Rhein in January of this year to make I.P. carriers for the new Mercedes E Class. This compression molding process allows metal inserts to be molded into a part. A flat metal plate, for example, is inserted into an I.P. carrier to support the airbag. Holes in the plate let resin (though not much glass) flow through to fill ribs on the other side.

Which LFT choice?

At this point, Faurecia has more experience than any other molder in choosing which LFT process is right for which part. Besides its GMT compression molding, Faurecia uses four other DLFT processes, two for compression and two for injection molding. All are in full-time production in Faurecia's Audincourt plant.

Choosing among these five LFT processes depends on labor and material costs, the strength requirements of the part, and part geometry. Cycle times for GMT and all DLFT processes are comparable, somewhere around 1 minute. GMT, however, has higher labor cost than any of the DLFT processes. Faurecia's GMT line needs eight downstream workers to trim parts, cut holes, and install hardware, vs. six workers for a typical XRE compression part and perhaps no workers at all for XRI, depending on how many holes a part requires.

Labor for secondary hole-drilling operations can be saved by molding holes into XRI parts. XRI allows much more extensive use of metal inserts to be molded into parts and is the best way to get glass content into complicated geometries. But one of the biggest values of XRI is its ability to control modulus locally through fiber orientation, depending on the location of injection nozzles and flow speed. In contrast, fiber orientation is random in GMT and in compression molded DLFT parts.

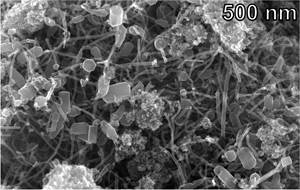

A key issue in structural part design is what balance of stiffness and impact strength is needed. "Stiffness is mainly fiber orientation, while impact strength mainly relates to fiber length," explains Faurecia's Dumazet.

"For XRI you need very precise prediction of flow velocity because velocity is what gives the fibers orientation," Dumazet adds. Flex modulus is doubled if fiber is oriented rather than random. With a 40% long-glass/60% PP compound, the flex modulus will be 653,000 psi in local areas where fibers are random, and over 1,000,000 psi in areas where fibers are oriented, Dumazet says. Multiple injection nozzles direct flow to create areas of fiber orientation and randomization. Up to 16 separately controlled nozzles are standard for Krauss-Maffei's version of XRI, and even more are possible.

On the other hand, weld lines formed where the flow lines meet weaken the part's impact strength, so they must be designed into non-critical areas like the edge of a punch out or better yet, a place where weakness is actually desired, like an airbag cover. Faurecia uses Moldflow software with in-house modifications to model fiber orientation in its XRI process.

In the development of a new part, Moldflow fiber-orientation modeling is carefully checked against dozens of specimens cut out from different locations on the part. Faurecia engineers may cut out and test as many as 25 specimens for impact strength. "From the impact strength, we can infer the fiber orientation," explains Faurecia process engineer Klaus Bamberg.

Faurecia also tests for local fiber distribution in compression molded DLFT parts by mixing in one spool of carbon-fiber roving with 47 spools of white fiberglass. The black carbon fiber strand gives a salt-and-pepper appearance to the molded part that reveals whether fiber distribution is homogeneous.

The ability to design random and oriented fibers into the same part opens new possibilities for Faurecia in DLFT molding. One of the first such applications may be car-door modules. These modules would replace sheet-metal stampings with a single XRI injection molded part in which all the electronic and mechanical functions are molded in. At least one major European car maker is evaluating such a door module now for 2005 model cars.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Why Long-Glass Molders Are Compounding In-Line

Compounding raw fiberglass directly into thermoplastic molded parts is growing rapidly in Europe, and now it’s coming here. D-LFT, as it’s called, promises to make large parts cheaper and stronger—but with new technological risks and higher up-front investment costs.

Read MoreNow Molders Make Their Own GMT Sheet

The latest sign of an upsurge of interest in direct long-fiber compounding by molders of reinforced thermoplastics is a technology that allows molders to produce their own glass-mat thermoplastic (GMT) composite sheet.

Read More