In today's challenging business environment, there is more emphasis than ever on finding ways to improve processes and increase overall process efficiency. Plastics processing of all types is energy intensive. By incorporating improved and consistent operating parameters, overall energy and operating costs can be reduced by up to 30% or more. An indirect result of these savings is a reduced carbon footprint and overall improvement in environmental conditions.

The primary processing machine will account for 35% to 60% of overall energy consumption. There, you can realize efficiency gains by upgrading or replacing the screw and barrel or investing in motor, drive and control technology. In some cases, it may make more sense to replace an older machine with a newer model to improve plasticating capability with reduced energy consumption, providing reasonable payback for the investment.

The focus here, however, is on the auxiliary equipment that surrounds and complements the main processing machine. By implementing small changes in equipment and processing habits, energy savings can be realized in these complimenting auxiliaries.

The auxiliary equipment surrounding the main process machine offers many opportunities to realize improved efficiency, including:

• Operate at a minimum processing temperature to lower the energy and load requirements of the cooling equipment.

• Use insulation in strategic areas to minimize heat losses in process supply lines and downstream components.

• Recover and/or remove waste heat using heat exchangers. Reject it outdoors or repurpose it to supplement other process requirements.

• Take advantage of outdoor ambient conditions to use “free cooling” to cut operating costs and supplement cooling requirements when conditions allow.

• Replace old motor and drive technology with more energy-efficient models.

• Replace under-sized equipment; Replace over-sized equipment - Use appropriately sized equipment for the process.

• Clean piping systems to enhance heat transfer and reduce pressure drop.

• Develop a culture of continuous improvement and process improvement. Find ways to streamline, introduce process consistency and further optimize the process and reduce waste.

Let’s take a look at these opportunities in more detail, and then delve into energy-savings tips for various auxiliaries you’re likely to have in your plant:

Process Parameters: Establish the optimum cooling or heating temperature (and time) parameters for the job. Determine temperature and flow profiles that will achieve the best result. Optimize part cooling times. Do not over-cool a part and waste time or energy. Do not dry material at higher than required temperatures. Find a good balance between the process temperature setpoint and dwell time needed for conditioning the part or material. This adds up to lower operating costs and improved production throughput.

Do not over-cool a part and waste time or energy.

In the case of chillers, for example, an increase of chiller process temperature of 1° F will save approximately 1.5% on chiller energy usage. Lowering the process-supply temperature will require more energy and is not as efficient. Actual conditions and equipment design will vary your potential savings.

Insulation: Insulation is one of the easiest ways to save energy and reduce inefficiency. In a cold-water process, use insulation on process piping to reduce heat gain from the environment. In a hot-fluid process, insulate high-temperature process piping to reduce heat losses between the temperature-control units (TCUs) and the mold, tempering roll, or other downstream equipment. In some cases, insulating process-fluid tanks and part-conditioning tanks can further reduce energy loss to the environment.

Heat Exchangers: Heat exchangers are used to transfer heat from one medium to another. The media can be gas, liquid or a combination of both. Heat exchangers can improve a system's energy efficiency by transferring heat (or cold) from systems where it is not needed or to other systems where it can be utilized. A simple example would be routing warm condenser air from an air-cooled chiller outside of a building during the hot summer months. In winter, exhaust dampers can be adjusted to add supplemental heated air to the work environment, lowering overall heating and cooling costs.

Process Piping Considerations: Look for blockage and flow restrictions in cooling channels. Clean the flow path and implement water treatment to minimize re-occurrence. Clean piping and open cooling channels will enhance heat transfer and reduce overall load requirements on cooling equipment. An internal pipe scale layer of only 0.06-in.-thick on a pipe wall can reduce heat transfer efficiency up to 12%. Eliminate bends, elbows, and flexible piping when possible. This will reduce overall pressure drops in the piping system and lower the demand on pumping systems (air and water applications).

Fix water and air leaks to improve system performance, eliminate waste and improve overall plant safety. Turn off idle cooling channels or shut down flow through unused equipment. This will minimize pump load and reduce heat transfer to the system by eliminating flow through idle machines and processes. Insulate process piping and equipment to reduce heat transfer to the environment.

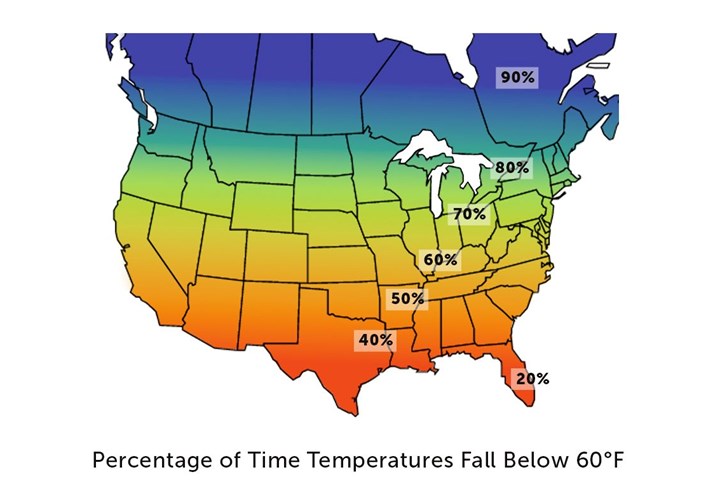

Free Cooling–Take Advantage of Nature: When ambient conditions allow, consider implementing “free cooling” systems to take advantage of outdoor ambient air conditions. This will reduce the load on chiller and cooling tower systems. This will save energy and lower the demand on the water system.

When temperatures are below 60°F, refrigeration systems can capitalize on low condensing operation, resulting in significant savings opportunities. Illustration: ACS Corp.

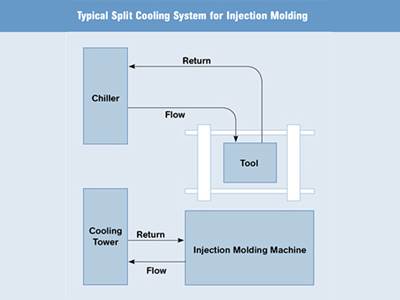

For chiller systems, a series of heat exchangers are used to isolate the water/glycol mix and provide heat transfer to the internal process cooling loop. When ambient temperature range is acceptable, the water will recirculate through the heat exchangers and bypass the chiller. This saves energy and uses the lower ambient temperatures to perform the heat-transfer exchange (lowering overall system operating costs). Due to changing climate conditions, most of these free-cooling systems would benefit from a water/glycol mix to provide freeze protection. Cooling towers do not typically use a glycol/water mix.

Consider replacing old motors on equipment with more energy efficient models.

In some cases, adiabatic cooling systems can be used to further enhance the heat exchanger cooling capacity on heat exchanger coils. While effective, they are not suitable for all climates and tend to have a longer payback period.

In cooling tower applications, variable speed fans and creative piping can increase cooling tower capacity and provide some preconditioning of process water (using heat exchangers). This will lower the overall energy consumption and reduce demand on other equipment in the process.

Chillers: Chillers typically account for 10-20% of the total process energy consumption. Your process will dictate the percentage of energy required.

Replace old compressor technology with newer, more efficient technology (reciprocating, scroll, screw, etc.). Consider compressor staging to better match the actual process load. In some cases, variable speed compressors can control variable load conditions with minimal energy waste. The goal is to minimize compressor cycling and prolong equipment life. Keep air-cooled condensers well ventilated and allow room for full cooling air circulation. Keep condenser filters clean to reduce pressure drop and keep equipment running and providing good heat transfer.

Variable Speed/Soft Start Drives: Implement variable-speed pumping systems to better regulate flow and pressure throughout the process. On large systems, it may make sense to monitor flow and pressure in key areas of a system to allow for more consistent cooling of loads under variable operating conditions. Excess flow/capacity can be routed back to the return tank, which can pre-condition the return water and lower the overall load on a chiller or cooling tower.

Cooling towers can be fitted with VFD drives and linked by a temperature sensor to the tank or sump. This will regulate fan speed based on tank temperature leading to lower energy usage and more consistent tank temperatures.

Large motors have a large in-rush current. By regulating the startup period using soft-start drives, a reduction in overall energy can be realized (if your process will allow).

Motors: Reduce the energy consumption of motors. A general rule to follow is: 1 Kw of fully loaded motor will cost approximately $1000/yr in energy costs. Actual process costs will vary. Install Variable Frequency Drives to better match motor load to the demand. New motors have higher energy efficiency ratings. Consider replacing old motors on equipment with more energy efficient models. Turn off motors that are not contributing to production. Monitor and maintain motors on a regular maintenance schedule.

Controls: Upgrade/retrofit older equipment control platforms with newer technology which includes more energy efficient components and improved control algorithms. Newer control panels typically utilize touch screen controls which are graphical and easy to follow and understand.

Dryers: If a drying system is used, it can account for up to 15% of the energy consumed in the overall process. The type of process you have will dictate the actual percentage of total consumption.

Install insulation on process piping. Use insulated drying hoppers to contain heat and minimize heat transfer to the environment. Use remote process heaters, when possible, to keep the heat source close to the drying hopper and minimize heat losses. Return air lines from the drying hoppers to the main dryer are typically not insulated.

Heat exchangers can be used to capture wasted heat and lower return temperatures to the desiccant dryer. Reclaimed waste energy can be used to pre-condition the process or regeneration air, heat the process space, or even provide supplement heat to other processes.

Consider updating older dryer control platforms. Monitor drying conditions to lower process temperature or adjust airflow with variable speed drives when the material demand is low or not being used. This will conserve energy and better condition the material going into the process. In some cases, material can be dried at higher dewpoint conditions. Some dryer manufacturers provide options to control the dew point of the circulating process air. This extends the regeneration cycle and can turn off heaters and blowers to conserve energy.

Regenerating by temperature (not time) is another good way to optimize efficiency in a dryer. Dryer designs vary and most Drying equipment suppliers offer “smart” energy efficient features with new equipment. If dryer equipment is old, the process may benefit by using newer, energy efficient designs that have a reasonable payback period.

Use insulated drying hoppers to contain heat and minimize heat transfer to the environment.

Find the lowest dryer process setpoint temperature and material residence time to adequately dry material. This can reduce energy consumption. Be careful not to compromise part quality.

Storage: Properly seal and store resin when it is not being used. Seal storage containers of material to minimize effects from ambient conditions. Consider using dehumidified, positive pressure air blanketing on large storage vessels (bins and silos) to minimize moisture migration into the material. The less exposure the material has to high moisture, ambient conditions the less time it will take to dry the material the next time it is being used.

Conveying Systems: Minimize the number of compressed air and self-contained motorized loaders. These self-contained devices are needed in your plant, but they can consume large amounts of energy. Consolidate stations into a centralized conveying system with overall less energy consumption.

Use oversized central filters and the correct filter media. Maintain this equipment on a regular schedule. Clean filter systems consume less energy and promote good material flow. They will allow the pump to run more efficiently with lower pressure drops.

Eliminate excess flex hose and excessive pipe bends. Replace worn-out piping and components and fix all leaks in the system. Inspect and tighten bolted pipe couplers (and coupler gaskets) on a routine schedule. Reduce overall system pressure drops and losses.

On conveying systems, make sure you match the equipment to the application. .

And remember to keep the wand in the box. Make sure the material supply is available to the system pick up device to minimize material shortages and wasted time with no material conveying. Use the correct material pick up device to allow material to flow without slugging and provide a good ratio of air to material. Optimizing material flow can improve conveying performance up to 10-15%.

Use the right equipment designed for the application. Match the receiver size to the throughput of the process machine and include options to enhance performance and filter cleaning. Optimize load times and filter cleaning operations. Use the right size pump/conveying line for the throughput requirement. Eliminate wasted time in the conveying process to save time and energy.

Size Reduction: Turn off size-reduction equipment that is not being used. Properly size equipment for the part dimensions and the throughput requirements. Develop routine maintenance procedures on size reduction equipment; check all main components. Keep bearings properly lubricated. Sharpen blades as needed and maintain proper clearance on the gap between the fixed knives and the rotating blades.

Monitor amp draws with an amp meter when feeding scrap parts. Do not overfeed. High amp draws indicate an overfeed condition and higher energy usage. Consider Soft Start to reduce in-rush starting current on large motors. Replace older motors with higher efficiency models. Consider adding PLC control on larger machines to monitor and better control the overall size reduction process.

Control Platforms: Simplify when possible. Upgrade controls to simplify operation and enhance monitoring. Add alarms to identify and signal “no-fill” or “overfill” process conditions or other critical operating parameters. Utilize hour meters to track equipment use and schedule routine maintenance.

Consider predictive maintenance monitoring controls (i.e. Industry 4.0) to track and provide long-term intelligence on the equipment in your process. Industry 4.0 monitoring systems leverage data and technology to help operators make smarter decisions. It is designed to help keep equipment running and avoid unnecessary downtime. Some suppliers also incorporate energy monitoring options to identify and improve the usage of energy throughout a process.

Develop routine maintenance procedures on size reduction equipment; check all main components.

Size Matters: Match your equipment selections to your process to maximize throughput and optimize energy consumption. Replace undersized and oversized equipment. In some cases, it may make sense to combine several smaller chillers or dryers into one large central system. Avoid running large chillers with little or no load. Consider current and future load requirements for the plant.

Implement Continuous Improvement Programs

Form a multi-discipline process team. Evaluate and establish process start-up operations and shut down procedures. Identify optimum parameters that are consistent with your process to eliminate major variations. Implement a continuous review process and look for ways to eliminate waste, turn off unused equipment and monitor and update your processes and procedures. All areas in your plant can benefit from reduced energy consumption (light fixtures, occupancy sensors, etc.).

Take advantage of Mother Nature.Setups like this take advantage of lower ambient air temperatures, to provide process cooling without refrigeration. Photo: ACS Group

Continuous improvement opportunities exist throughout the company. Establish an improvement team to work together on a routine basis and look for energy-saving and ways to streamline processes. Don’t be afraid to consider non-traditional approaches that may work for you.

- Optimize and record all parameters that provide the best results.

- Document and record settings. Create process procedures and documents.

- Do not change optimum settings; follow the established procedure.

- If issues occur, discover the root cause that created the inconsistency.

- Follow a consistent/repeatable process.

- Update/repeat/refine—continuous improvement.

- Make continuous improvement part of the business culture.

Work with the Experts

Contact your local utility companies. They can assist in providing energy audits, show ways to improve your process environment, and in some cases offer energy-saving rebates based on improvements made with proper benchmarking.

Your equipment supplier is an excellent source of information and support. Let them work with you to update and improve your equipment. They are an excellent resource available to come in and sit down with you to discuss new equipment and systems that will help improve your bottom line and lower your carbon footprint.

About the Author: Joseph Dziedzic is the manager of the technical sales team at ACS Group (AEC, Cumberland and Sterling). In this role, he and his team support the customer before and after the sale to ensure the correct application of product design and proper installation of process systems. Prior to this, Dziedzic has worked as the product development manager for ACS Group and was responsible for product development and marketing activities for the company’s material handling and water process solutions product groups. Contact: 847-273-7700; jdziedzic@acscorporate.com; acscorporate.com.

Related Content

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreNPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

Where Are You Using Energy?

Few plants are able to accurately divide up their energy consumption by where it occurs, despite the fact that this is relatively easy to do.

Read MoreEnergy Miser: For Energy-Efficient Water Cooling, Raise Temperatures to Cut Demand

Many plants use chilled-water temperatures that are far lower than are actually needed by the process. This has a direct effect on the cost of chilled water.

Read MoreEnergy Miser: Use Less Energy to Generate Compressed Air

Last month, we addressed how to minimize your plant’s usage of costly compressed air.

Read More