MATERIALS AND ADDITIVES AT NPE: Spotlight on Performance, Economy, and Sustainability

Lots of news in engineering thermoplastic compounds, TPEs, and purging agents, plus a wide range of colorants and additives.

New advances in a broad range of materials and additives will figure more prominently at NPE2015 than in previous years. Based on news that was available to us preshow, you can expect to see a variety of new high-performance engineered compounds and TPEs for applications from automotive and industrial to healthcare and packaging. There are also new purging compounds, hybrid styrenic/olefinic moldable foam resins; mPE resins for cast stretch film; customized recycled PP and HIPS compounds; and the latest biobased PHA material advances.

In new additives, look for the “Italian and Spanish Invasion,” with two companies making an entry into North America. There are also new electrically conductive carbon blacks and thermally conductive graphites; additives for enhancing recycled plastics; a compatibilizer for engineered plastics; biobased plasticizers; new mold releases for rotomolding and “sustainable” alternatives to aerosol cans; and emerging applications for nucleating and reinforcing agents.

To appreciate the increased emphasis on materials at this year’s show, take a look at three special programs that SPI has initiated for NPE2015, March 23-27 in Orlando, Fla.

• The Customer Service Centers Program was designed for materials and additives suppliers to sign up for conference space off-site from the Orange County Convention Center for one-on-one meetings with customers. At NPE 2012, there were six such companies, but more than twice that number have signed up for this show, including Dow Chemical, DSM Engineered Plastics, DuPont, Eastman Chemical, ExxonMobil Chemical, LyondellBasell, PPG Industries, and Westlake Chemical.

As Tony Deligio, Plastics Technology senior editor, blogged in October, materials companies generally believe that visibility at this event is more crucial than in the past. He cited Peter Smith, CEO of additives supplier Addivant, on the shift in importance from China back to North America, and therefore NPE. “I think what we are going to see now is a balance,” Smith said. “I don’t think China is going to disappear, but I think North America will come back in such a major way that it will be the go-to location for the next generation of equipment and for the next generation of polymers; and therefore, if you’re in the business of processing polymers, there won’t be a better location than NPE.”

• The NPE2015 Startup Garage was developed by SPI in partnership with the new-venture tracking firm Start.Up Directory. More than a dozen startups signed on to exhibit their innovations in bioplastics, polymerization, resin processing, antimicrobial polymers, recycling, and 3D printing.

Among materials and additives innovations at the Startup Garage, look for “bio-composite” polymers with up to 40% renewable content based on plant matter from Biobent Polymers. There will also be resins from cycleWood Solutions, produced from lignin derived from papermaking byproducts. LDPE-like film grades are 100% compostable, while injection molding grades are available in either compostable or sustainable versions (blended with polyolefins). And TiFiber will display antimicrobial polymers that exhibit broad-spectrum activity against bacterial species, including drug-resistant strains. Among potential applications are medical devices and consumer disposables.

Also look for graphene priced for high-volume plastic applications from Garmor Inc., which has developed methods for incorporating graphene into plastics and shares this know-how with customers.

• The Vinyl Save Lives booth of the Flexible Vinyl Alliance, an SPI affiliate, demonstrates how plastics, and specifically PVC, “save lives.” Showcased items include a portable medical isolation containment unit similar to those used in Africa and elsewhere to isolate patients and protect medical personnel and the populace from the spread of infectious diseases such as Ebola and SARS. Personal-protective equipment such as garments, masks, and floor covers will also be on display.

HIGH-PERFORMANCE ENGINEERED PLASTICS

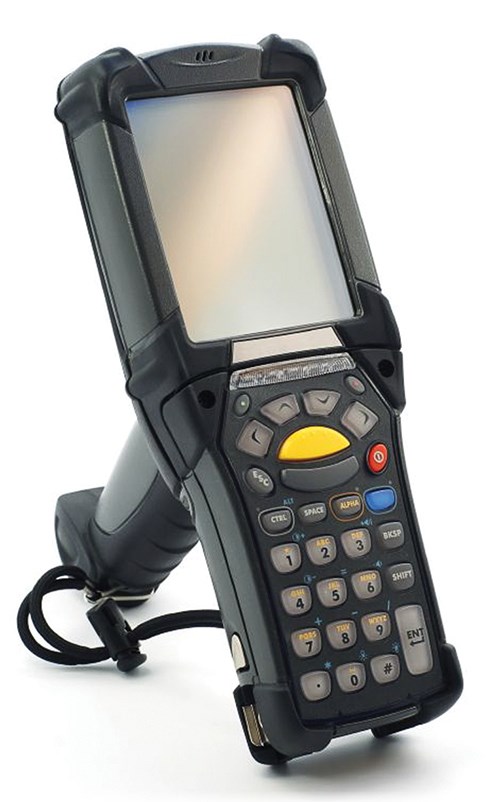

RTP Co. will feature an assortment of applications for its engineered thermoplastics, with a couple of key highlights. One is the recent expansion of its Very Long Fiber reinforced PP (PP VLF) portfolio, which now includes a range of low-emission products. International legislation and automotive OEMs have identified the need to reduce odor, fogging, and total VOCs to improve air quality and safety in automotive interiors.

The low-emission PP VLF compounds are designed to provide exceptional strength, stiffness, and dimensional accuracy, with reinforcement levels of 20-50%. They have been tested by approved outside laboratories according to German Automotive Industry (VDA) test methods for odor, fogging, and total VOC emissions. VDA test results have shown the new compounds to meet or exceed the OEM requirements in all three categories. These VLF compounds are targeted for use in applications such as instrument panels, door module carriers, overhead and center consoles, seating, load floors, pedal boxes, spare tire covers, and storage bins.

Also targeting automotive is the relatively new firm of Lehvoss North America, whose new nylon 66 compounds are said to produce gear wheels that are more resilient than those of acetal, nylon, or PBT, even at elevated temperatures. Luvocom 1-8181 and 1-8520 are nylon 66 fortified with carbon fibers and impact modifiers; they were developed specifically for automotive gear wheels subject to high stresses. The strength of these compounds at 240 F/120 C is said to be around 80% higher than standard nylon 66 compounds. They also exhibit increased impact strength.

Depending on the component’s service life, the continuous operating temperature is 240 F/120 C and up to 302 F/150 C for short periods. This combination of properties is said to expand the engineering envelope for reinforced thermoplastics.

RTP will also highlight the release of unique tribology data for designers of medical devices to assist in selection of thermoplastic materials. Engineers on hand at the booth will present new data based on an innovative friction test designed to accurately predict behavior in single-use medical devices. Using this new method, RTP engineers tested base resins in a variety of combinations with friction-reducing additives.

DSM Engineered Plastics will highlight several of its recent material developments, including its new portfolio of Akulon nylon 6 and Arnitel copolyester for thin films in flexible food packaging. The company claims a major recent advance in processing nylon blown films, thanks to improved crystallization properties of its Akulon XS. It has an extended processing window, opening up opportunities in designing coextruded multi-layer and monolayer film structures.

Also new from DSM will be its next-generation Diablo high-heat-resistant grades in its Stanyl nylon 46 and Akulon nylon 6 portfolio (see December Keeping Up), which are aimed at auto engine components such as air-intake manifolds, ducts, and charge-air coolers.

DSM will also display developmental thermoplastic composite tanks for compressed natural gas, and uses of Stanyl nylon 46 and Stanyl ForTii nylon 4T for high-performance DDR4 memory connectors (see Sept. ’13 Starting Up). DuPont will emphasize its collaborative approach to innovation. DuPont R&D and application development teams will host seminars and panel discussions to stimulate new ways

to improve performance, cut costs, and enhance sustainability of components, structures, and systems used in packaging, automotive, and healthcare.

Topics include design approaches that help extract the value of advanced materials like

nylon, acetal, PPA, and polymer modifiers; automotive lightweighting strategies; materials suited to drug-delivery devices; and novel approaches to tackling recyclability challenges.

Albis Plastics will showcase its latest engineering compounds and new applications, with a focus on its Alcom PC, ABS, and ABS/PC products for automotive lighting.

These include LD (light diffusion) grade for homogeneous, almost loss-free light diffusion; LB (light blocking) grade for high light intensity and reflectance; and LG (light guide) grade for optimum light guidance combined with high toughness and

good resistance to heat distortion.

Techmer ES, will show the latest additions to its Hifill PEEK LSB (low springback) portfolio of PEEK compounds for the oil and gas industry. The LSG compound is specifically designed to address the springback challenges in the creation of backup rings used in oil and gas sealing systems.

The process starts with molding billets, which are then machined into rings based on OEM specs. They are then scarf cut for field use. However, once scarf cut, they either spring in (overlap) or spring out (creating a gap), depending on where in the billet the ring was sectioned. Using the LSB compound is said to result in low springback and meets OEM physical performance specifications. Previous products addressed either the springback or met the physical property requirements, Techmer ES says.

At the show, Techmer ES will also debut of a new line of materials for additive manufacturing/3D printing. The company says it will be supplying compounds for all processes, including FDM, SLS, and large-part printing.

AGC Chemicals will feature some of its new high-performance fluoropolymer compounds (see February Keeping Up).

MORE NEW TPEs EMERGE

Elastocon TPE Technologies will feature five new TPEs. Four are additions to the company’s Elastocon 8000 Series of multipurpose TPEs that can be overmolded, extruded, blow molded, or compounded.

• 8150 is a black 48 Shore A TPE with rubber-like properties providing a matte surface finish and good UV stability. It has passed FMVSS302 flammability specifications for auto interiors.

• 8088N is a black 88A grade for automotive applications.

• 8078B is a black 82A grade offering rubber-like properties and UV stability.

• 8088BL is a colorable 88A, FDA-compliant and flame-retardant grade that offers UV stability, high impact resistance, and reduced coefficient of friction. It, too, is suitable for auto interiors.

The company’s CLR Series of very tough and super-clear TPEs also will be highlighted (see Nov. ’14 Keeping Up). These oil-free, odorless, and tactile-finish materials come in 65A and 75A durometers. FDA compliant, they can be injection molded, extruded, and

overmolded onto PP and other materials, making them well suited for medical applications and toys.

Lubrizol Engineered Polymers will highlight the latest advances in its pioneering aliphatic TPU, biobased TPU, and adhesive TPU solutions for applications in electronics, industrial, medical, and sports/recreation industries.

Teknor Apex is launching a new series of TPEs for colorful, touch-friendly personal electronics like fitness trackers and smart watches, plus Sarlink ME-2600 styrenic block copolymers for automotive window encapsulation and weather seals. The latter are said to have 50% higher flow than Sarlink TPVs. Teknor will also feature a diverse range of capstocks for outdoor rigid profiles as a result of its recent acquisition of Viking Polymers (see February Keeping Up).

PURGING COMPOUNDS EVOLVE

Mould Plus International will launch its new and improved Ultra Purge grade 5150. This is an HDPE-based hybrid purging compound that does not contain glass fibers. An evolution of the firm’s Ultra Purge 5050, the new grade is said to make purging faster and more user-friendly. It is also hot-runner safe, food-contact certified, and can be used on all thermoplastics processing machines.

The new compound uses new Ultra-X proprietary technology that, when combined with the Ultra Purge active ingredients, creates a very efficient purging agent capable of deeply dissolving colors and carbon deposits. According to Mould Plus, Ultra-X fluidizes the polymer, allowing the Ultra Purge grades to flow through very small gates—down to 0.2 mm—and at the same time adds scrubbing power without harming the screw, barrel, or hot runners. It has been shown to increase the cleaning efficiency

of Ultra Purge by up to 30%. This technology will be applied to other grades of

Ultra Purge in the future.

RGL Sales will highlight its proprietary Clean Plast purging compound. This chemical purging agent comes in pellet form and is said to be safe to use on hot runners, valve gates, and sensitive molds, as it does not contain any harmful abrasives. The company claims that only prime ingredients are used in its formulations. These use a chemical purge additive blended into a carrier resin. The purge agent is said to break down contamination, and the carrier resin flushes it out of the barrel, mold, or tooling.

Clean Plast formulations are now available for all types of plastics processes and tooling, including PET preforms and precision molds. For especially tough jobs, custom formulation is available, as is on-site training.

Also to debut at the show are high-temperature compounds for purging “super-engineering resins” such as PEEK, PES, PEI, and LCP. They come from Sun Plastech (see January Keeping Up).

OTHER MATERIAL NEWS

Sekisui Plastics Co. will introduce new grades of its Piocelan moldable bead-foam resin—a hybrid of styrenic and olefin components. The company uses a proprietary technology to add polyolefin characteristics to the foam, which significantly improves the shock resistance, chemical resistance, and abrasion resistance of EPS. The foam can be molded into shapes using conventional EPS equipment.

Used in automotive components for energy absorption and weight reduction, the new grades boast improved strength, heat resistance, and flame retardancy. The foam is also used as a packing material for transporting automotive components, IT equipment, and home electronics.

In addition, Sekisui will present several developmental product technologies, including nylon foam that exhibits excellent high- and- low- temperature resistance and is said to be easily formable into complex shapes; elastomer bead foam with very low compression set and high flexibility; and heat-resistant acrylic and polyester foams that are easily formed or machined into complex shapes as core materials for carbon-fiber composites.

Among its featured product developments, ExxonMobil Chemical will highlight Exceed mPE resin designed for high-performance cast stretch films. It boasts performance benefits such as cling retention at high stretch ratios, as well as processing advantages, including high output and web stability.

CTC Plastics will highlight the latest in its line of custom compounds based on recycled PP, HIPS, and automotive-certified PP copolymers. The company recently added a new 92-mm corotating twin-screw compounder, which allows it to provide customers with enhanced toll compounding.

Biopolymer supplier Metabolix will focus on the latest application developents for its PHA bioplastic, including its use to modify PLA and PVC, PHA barrier coatings on paper/cardboard, and PHA micropowders.

ADDITIVE NEWS

As with materials, you can expect to come across lots of new additives and colorants from the major suppliers, including two new entrants on this continent.

Italy’s REPI (U.S. office in Gastonia, N.C.), will showcase its latest liquid colorants and additives, along with its proprietary dosing and metering equipment. It plans to exhibit its U2011 Dosing Unit and Light Meter with live demonstrations.

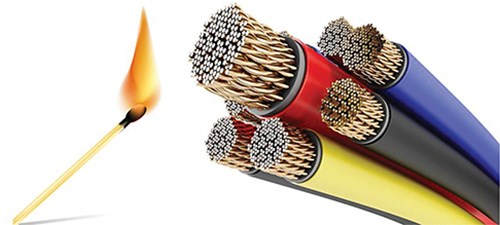

Spain’s Tolsa Group (Suwanee, Ga.) will feature its Adins range of halogen-free flame-retardant and thermal-insulation synergists, available in powder form or as concentrates. Based on a novel technology that uses natural silicates, these additives boast improved processability and reduced cost. They are said to be characterized by a very high surface area and special morphology with performance that can be tailored for wire, cable, and electronic components. With sepiolite (a complex magnesium silicate) as a carrier, the active flame-retardant dosage reportedly can be reduced, thus decreasing overall cost.

Tolsa offers a range of FR synergists including Adins Clay 20 and Clay 80, and Adins

Fireproof series of additives. These products are said to work synergistically with most

flame retardants in plastics, strongly boost char formation during combustion, and protect polymers from further fire propagation. Smoke and heat release are reportedly reduced considerably. The Adins clay series improves thermal and fire-insulation properties of extruded polystyrene foams (XPS), reducing their cell size and increasing cell density. The additives reportedly can replace HBCD in XPS foams.

Orion Engineered Carbons will feature five new specialty carbon blacks for pressure pipe, wire and cable, and conductive products:

• Arosperse 5-183A is a soft-beaded furnace black for semi-conductive insulation shields for medium-voltage cables. With low sulfur impurities and low sieve residues, it is said to be a very clean and easily dispersable grade. Potable water pipe and electronics packaging are other applications.

• Printex zeta A is designed for pressure piping used in gas and water distribution. Its high chemical purity and physical cleanliness is said to minimize taste and odor effects. Low compound moisture absorption, excellent microscopic dispersion, and UV protection are said to ensure a smooth, defect-free pipe.

• XPB 552 has a medium specific surface area, giving polymers conductivity and antistatic properties suited to auto body parts that require conductivity for electrostatic coating. It’s also useful for antistatic electronics packaging.

• XPB 538 has an extremely high-specific surface area with very high structure level and cleanliness. It reportedly achieves higher conductivity at lower loadings than regular conductive blacks for applications such as engineered plastics, wire and cable, and lithium-ion batteries.

• Printex HV for high-voltage cables features high cleanliness and dispersability and is said to impart excellent surface smoothness and high conductivity to semi-conductive compounds.

Imerys Graphite & Carbon will present the latest in its line of Timrex synthetic and natural graphites that offer thermal conductivity, electrical conductivity, lubrication, and gas barrier in seals, water meters, heat sinks, geothermal pipes, and LED light sockets.

Imerys will also feature its latest Ensalco high-purity, easily dispersible carbon blacks that provide electrical conductivity in electronic packaging, fuel hoses, flooring, power cable, conveyor belts, and ATEX (explosive atmosphere) applications.

Americhem will bring out its new nDuramax UV stabilizer masterbatches for films,

including label, window, and photovoltaic films of PET, PE, and ionomer.

Struktol Co. of America will show process additives it has developed for reclaimed/recycled plastics and for plastic compounds with recycled content. The additives can be used in a variety of resins from polyolefins to engineered plastics. For engineering resins, two new products combine a compatibilizer and lubricants to aid incorporation of mineral and/or glass fillers with improved flow properties as well as mold release. Better processing, improved surface quality, and in some cases better physical properties are claimed.

Struktol TR 229 is for PC, PC/ABS, and nylon 6 and 66. It can be used in FDA-approved applications. TR 219 is for nylon 6 and 66 but has also been shown to be effective in recycled PET and PBT, particularly when they are contaminated with other plastics.

For recycled PP, Struktol has three new additions. RP 11 is a unique lubricant package that boasts an unmatched combination of viscosity reduction and mold release at loading levels as low as 0.2%, resulting in better melt flow and allowing for higher

use of regrind/recycled content. RP 06 provides similar viscosity modification and mold release, combined with low odor and volatiles as is desired in automotive applications.

RP 37 is said to provide unmatched viscosity modification and lubrication in recycled compounds and resins containing high levels of PE contaminants.

Struktol will also feature RP 17 combination lubricant/odor neutralizing mask, which

was originally designed for wood-filled plastic compounds. It has been modified for use in a variety of other plastics that require the multifunctionality of lubrication, mold release, and odor reduction. It can be used in recycled applications as well as auto interior compounds where neutral odor may be required.

Making its first appearance at NPE is Vertellus Specialties, which will showcase the latest in its family of ZeMac copolymers (1:1 alternating copolymers of ethylene and maleic anhydride) shown to be excellent compatibilizing agents. Key applications include glass-fiber sizing, laminated films, microencapsulation, pigment dispersion, hot-melt adhesives, heat-seal packaging, and plastics compounding applications. Both ZeMac E60P powder and Extent masterbatches are reportedly very efficient chain extenders for nylon, PBT, and other engineering plastics. They are said to increase relative viscosity along with strength, stiffness, elongation, toughness (especially at low temperatures), and HDT.

Also new from Vertellus will be a line of biobased plasticizers for PVC, biopolymers, and polyester-based TPEs.

Stoner, Inc. will highlight TraSys mold releases for rotational molding. Following its recent acquisition of the TraSys product line from DuPont to complement its Releasomer and Stoner brands, Stoner reportedly has become the world’s largest supplier of rotomolding release agents. TraSys products are competitively priced and water-based.

iD Additives will showcase its line of mold releases offered in its new Air Atomizer Sprayer, intended to eliminate the need to dispose of aerosol cans. These units—which are the same diameter as an aerosol can, are said to provide a uniform spray of mold release without CFCs or other dangerous propellants, and are refillable and rechargeable. The company’s Air Atomizer Sprayer line now include three mold-release products, all of which meet FDA specs for use in food and medical products made of ABS, acetal, acrylic, nylons, PC, polyester, PE, PP, and PS. They are said to provide more releases per spray with no mold buildup, as well as “hang-up” prevention for even the most challenging parts. Products include “100% natural” Organic Mold Release, silicone oil release, and Neutral Mold Release containing white mineral oil.

Jungbunzlauer will showcase its range of Citrofol esters—biobased plasticizers compatible with PVC, aclylics, PUR, and biopolymers such as cellulosics, PLA, and PHA. They are said to be drop-in solutions at a competitive price. One of the more recent grades is Citrofol Bll, a fully degradable citrate ester suitable for standard plastics and biobased plastics and particularly well suited for mulch films or films used to prevent soil erosion. It is certified to meet U.S. ASTM D6400 and European DIN EN 13432 compostability standards.

MillikenChemical will highlight Hyperform HPN 210 M, the first of its new family of nucleators based on a “breakthrough” technology (see Oct. ’14 Keeping Up). Based on a novel organic salt, it promotes a unique crystalline orientation that improves the mechanical performance of HDPE to levels approaching that of PP impact copolymers.

Milliken will also show the expanding use of its Hyperform HPR-803i reinforcing agent (a synthetic magnesium-based reinforcing fiber). Since its 2009 introduction, it has gained significant use in PP compounds for auto interior components such as tailgates and B-pillar trim (see April ’14 Starting Up).

Related Content

Masterbatches Reduce Gloss in PLA and PETG 3D Printed Products

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.

Read MoreK 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MoreRead Next

APPLICATION: Synthetic Reinforcement Used in PP Door Trim

Milliken's Hyperform HPR-803i magnesium-based reinforcing fibers adds exterior door trim to its cache of automotive applications.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More