MATERIALS AT NPE: All Market Sectors Benefit from Large Crop of New Materials

NPE2012 News Wrap-Up: Materials

Higher-performance and easier processing PE film resins for packaging, a one-pass crosslinked PE for photovoltaic (PV) wire and cable, several higher-performing nylons and TPEs, “greener” plastics, and enhanced styrenic and PC resins are among the new materials that made their debut at the big show in Orlando, Fla., last month.

Higher-performance and easier processing PE film resins for packaging, a one-pass crosslinked PE for photovoltaic (PV) wire and cable, several higher-performing nylons and TPEs, “greener” plastics, and enhanced styrenic and PC resins are among the new materials that made their debut at the big show in Orlando, Fla., last month. About 50 new resins and compounds were launched for packaging, automotive, electronics, building /construction, medical, sporting goods, and other consumer and industrial applications.

NEW POLYOLEFINS FOR FIL M, WIRE & MORE

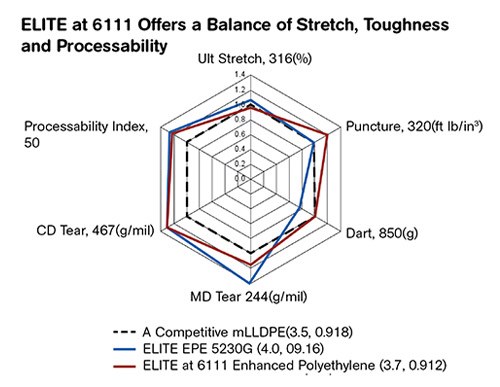

Dow Chemical Co. (dow.com), introduced Elite Advanced Technology (AT) PE resins to meet growing demand for higher-performance films, particularly for sealant, stretch-wrap, and stretch-hood film for food other consumer and industrial packaging. Based on patent-pending “post-metallocene” technology, Elite AT is made with a non-metallocene, single-site catalyst. Resulting materials are said to offer consistent, high-performance seal properties along with advantages in optics, stiffness, toughness, processability, and organoleptics, making them well suited to a wide variety of vertical-form and horizontal form-fill-seal applications. They also resist gas fading in tough warehouse environments. There are three initial offerings:

•A blown film sealant grade that has metallocene properties and the performance of LLDPE but with faster processing;

•A stretch-hood film grade as a replacement for EVA, boasting good dart impact, puncture, and tear resistance;

•A stretch-wrap cast film grade for high-speed applications that boasts much better toughness, less leftover unsaturation, good drawability, and 20-25% higher extensibility than metallocene resins. (Next up: new shrink and barrier film grades.)

Dow also added new Sealution 210 to its Sealution Peel Polymers, a line of ready-to-use, single-pellet olefinic formulations for easy-open packaging made from polyolefin blown and cast films. It boasts higher clarity for packaging such as fresh-cut produce wrap, clear tops for PP dairy cups, and microwavable

stand-up pouches. It supplements earlier grades, such as Sealution 140 (launched at K 2010 in Germany), which had lower clarity for applications such as cereal bags.

PolyOne Corp. (polyone.com) unveiled Syncure Solar, a new technology for PV wire and cable. A UV-resistant, XLPE system, it reportedly offers UL 4703 and VW 1 compliance in one material,

essentially replacing the two different materials—XLPE for insulation and PVC for jacketing—normally used. The material’s compliance with PV wire specs as well as the UL 44 standard for interior wiring allows it to be used seamlessly from the outside to the inside of a building in USE-2 (underground service applications), thereby streamlining installation and eliminating the need for a junction between interior and exterior wiring. As a one-pass extrusion solution, it leads to faster production and lower overall system cost. Combining insulation and jacketing also allows for a thinner coating (60 mil vs. the typical 75 mil).

There was news from Asahi Kasei Plastics North America (asahikaseiplastics.com) in glass-reinforced, chemically coupled PPs. Thermylene P9 is a short-glass reinforced grade described as a “nylon alternative” due to its enhanced temperature resistance. Applications include auto air-intake manifolds and other underhood parts. Due to its low specific gravity, it can enable weight reduction of 15% or more.

Thermylene P8 uses advanced coupling technology to provide a high strength alternative to long-glass PP. It’s used in car door modules, motor housings, sunroof frames, shifter bases, etc.

Thermylene PR contains post-consumer recycled (PCR) content.

And Thermylene P4 is an FR grade without decabromobiphenyl ether to satisfy new environmental regulations. It’s offered with glass, talc, other mineral fillers, or unfilled.

NEW AND IMPROVED NYLONS

BASF (plasticsportal.com/usa) introduced to North America its new high-impact Ultramid Structure materials, long-fiber reinforced nylon 6 or 66 that was recently used to produce the world’s first all-plastic wheel for a concept Daimler smart car. The wheel is over 30% lighter than a standard aluminum wheel and shows potential for mass production (see Dec.’11 Starting Up).

Other relatively new nylon offerings highlighted by BASF included Ultramid Endure, its high-heat nylon 66 family designed to replace metal in underhood applications, and Ultramid BG50XFi, an impact-modified nylon 6 developed for lawn/garden and other large, thin-walled injection molding applications that require

custom colors, toughness, high gloss, and UV resistance. It is said to be suitable for replacing painted PC/ABS and was chosen by a major automotive OEM for interior use due to its molded-in color, excellent weatherability, and high-gloss surface.

Invista (invista.com) introduced the latest addition to its Torzen line of nylon 66 compounds. Torzen Marathon is intended to fill the gap between standard nylon 66 and higher-temperature nylons. It’s said to broaden the application potential for nylon 66 to continuous use at 210 C (vs. 180 C normally), while maintaining a peak temperature resistance of 240-250 C. It reportedly retains more than 90% of original tensile strength after 1000 hr at 210 C, while conventional nylon 6 and 66 show about 50% retention. The new grade also offers as much as 50% higher flow.

High-heat nylon 66 grades aimed at engine and electronic applications were also unveiled by Radici Group Plastics (radicigroup.com/plastics), which highlighted three new additions to its Radilon line. ABV250 is a 35% glass-filled nylon 66 with heat resistance up to 210 C. It reportedly can replace PPA, PPS, and nylon 46. Radici will soon launch a next-generation family, not based on nylon 66, with heat resistance to around 230 C.

Radilon A RV500 RW 339 nylon 6 and Radilon S URV nylon 66 are two new highly filled grades designed to replace metal, SMC and BMC thermoset composites, and PUR.

EMS-Grivory (ems-grivory.com) showcased its expanded line of Grilamid L nylon 12, designed to replace rubber in media conveying systems. It is also now producing Grilamid 2D nylon 612, Grilamid 2S nylon 610, and Grilamid 1S nylon 1010 for tubing and connectors.

A. Schulman, Inc. (aschulman.com) launched Shulamid 612 IC 4005W for industrial fluid management. It can be extruded in smooth and corrugated mono- and multi-layer tubing and has 10% higher burst pressure and 20% higher heat-resistance than nylon 12.

Also new is the Schulamid HM series of high-modulus, high-strength nylon compounds, which incorporate 40% to 65% glass, carbon, or aramid fiber while maintaining high flowability and excellent surface appearance.

Asahi Kasei showed off its Leona LG long-glass nylon 66 and 66/6I for applications requiring superior fatigue and creep resistance, modulus greater than 20 GPa (2.9 Mpsi) with good surface finish, or FR grades with excellent impact strength.

LOTS NEW IN TPEs

BASF introduced two additions to its Elastollan TPU line. Grade 785 10HPM boasts mproved compression set at high temperatures, excellent surface reproducibility, and resistance to chemicals and fuels. Available in several hardnesses, its “feel” can range from velvety to leather-like. It was developed to meet “fail-safe” cable specs for antilock braking systems. It meets ISO 6722 Class D at 150 C vs. 125 C for typical TPUs. BASF foresees under-hood applications such as seals or hoses to replace rubber or other TPEs.

Elastollan 1185A 10HFFR is a low-smoke, halogen-free FR polyether TPU for continuous use at 150 C in tight-space automotive and wire and cable. It boasts excellent abrasion resistance, toughness, very good low-temperature flexibility, hydrolytic stability, and fungus resistance. It is also said to be much easier to color—including true blacks, reds and greens.

Lubrizol Corp. (lubrizol.com), which recently acquired Merquinsa of Spain, showcased new Pearlthane D11H92S and D11H95S TPUs—92 and 95 Shore A hardness, respectively—based on polycaprolactone. Designed with Merquinsa’s “H” technology, they are targeted for industrial high-pressure hydraulic seals, offering improved flow properties and high hydrolytic resistance. Both offer low compression set at high temperatures and can be injection molded with extremely short cycles,

the company says.

Kraiburg TPE (kraiburg-tpe.com), which has specialized in styrenic TPEs, launched two new classes of specialty TPE materials. One is a series of blends based on olefin block copolymers (OBCs), said to provide good flow and mechanical properties, resistance to skin oils, and enhanced strength. They typically span the 60-80 Shore A hardness range and are are suited to overmolding onto glass-filled nylon for medical applications such as drug-delivery devices.

Also new are TPE polar alloys that are said to provide a silky, non-stick surface along with good oil and chemical resistance and excellent bond strength to ABS and PC. Their viscosity can be adjusted from low to high flow for injection molding auto-interior grips and knobs or sporting equipment. They are also designed for cable extrusion, especially for consumer electronics headsets, where skin oil resistance and smooth surfaces are desired.

Star Thermoplastics (starthermoplastics.com) showed a line of TPEs that are said to mold and perform better than TPVs and are more attractively priced. Advantages cited for StarPrene TPEs vs. TPVs include similar flow properties but better color consistency, better tensile strength and elongation, and no need to dry before processing. Star claims it can “clone” or provide formulations that duplicate any competitive grade of TPVS for applications ranging from automotive, appliances, and electrical products to healthcare and packaging.

Elastocon TPE Technologies (elastocontpe.com) featured a new high-impact, semi-rigid TPE. Available in black, 9050BX has a 50 Shore D hardness—one of the hardest grades on the market. It is offered as a cost-effective alternative to TPOs and TPVs for trim rings and panels for consumer electronics and transportation equipment interior instrumentation.

Elastocon also has new addition to its 8000 series of multi-purpose TPEs. The 80 Shore A grade 8078NL boasts a high softness and superior scratch and mar resistance for uses ranging from automotive cup holders and storage bins to a broad range of consumer and industrial goods. Also new is the Elastocon STK56PA line of TPEs formulated for overmolding onto nylon, with improved durability, high scratch/mar resistance, and dry-touch feel.

Alliance Polymers and Services, LLC (apstpe.com), the exclusive North American distributor of Maxelast SEBS-based TPEs made by China’s Polymax Elastomer Technology Co., featured two new extrusion grades in the Maxelast D01-017G series. Available in Shore hardnesses of 70 A and 87 A, these grades are said to include high flexibility, built-in antimicrobial properties, and cold and aging resistance. They are targeted to replace plasticized PVC seals in refrigerators and freezers. Also new is Maxelast D01-0421, a nontoxic, odorless grade for cast film that is said to eliminate shortcomings of disposable PVC, PE, and rubber gloves. Lighter weight, softer feel, and no noise caused by friction are cited.

Meanwhile, Kraton Polymers (kraton.com) featured some of the many innovative applications that exemplify the shift in its Kraton SBS portfolio from traditional asphalt and roofing sealants and adhesives to a broad spectrum of medical, personal-care, wire/cable, automotive soft skins, and faux-leather uses.

Included are new compounded grades aimed at replacing PVC in medical applications such as IV and blood bags, and a new SBC–based compound that is billed as a drop-in replacement for PVC in slush molded auto airbag covers, consoles, and door trim. It offers improved processability and impact resistance, plus lower specific gravity that results in up to 40% weight reduction. Other slush-molding applications include an extrusion-coated Kraton/polyolefin skin over PUR foam, featured in the seat of a golf cart and applicable to a broad range of other seating.

‘GREENER’ PLASTICS SHINE

Brazilian chemicals behemoth Braskem (braskem.com) was the sponsor of NPE’s Sustainability Pavillion, which highlighted key sustainable technologies, including Braskem’s sugarcane-based Green PE. Braskem products were processed by several companies at the show, including two running Green PE: Bekum America blow molding 10L bottles and Davis-Standard extruding cast film.

Lubrizol highlighted Merquinsa’s new line of Pearlthane Eco bio-TPUs that range in hardness from 70 Shore A to 55 Shore D with renewable material content of 24% to 80%. They are said to offer the same thermal, chemical, and hydrolysis resistance as standard TPU and have been tested in the sports and recreation, electronics, and transportation uses.

TeknorApex Co. (teknorapex.com) highlighted the progress of its new Biovinyl flexible PVC compounds made with Dow’s nonphthalate Equilibrium seed-oil derived plasticizers, which offer better thermal stability and color hold than conventional PVC compounds. Trials with two developmental compounds for profiles,

seals, gaskets, and irrigation tubing showed the biobased plasticizers to be 10% and 16% more efficient than DEHP and DINP, respectively, allowing for lower plasticizer levels. Over 80 Biovinyl applications have been developed. Consumer products were the earliest adapters, driven by the “green” movement. Among the first commercial uses in the U.S. are a line of “flip-flop” sandals by Okabashi Brands and a range of shoe welting made by custom extruder Barbour Plastics. Other developments range from automotive trim, weather stripping and gasketing to medical, flooring, wire/cable, and lawn/garden

applications.

Radici launched new Radilon D nylon 610, made from up to 60% sebacic acid from castor oil. It can compete with nylons 11 and 12 because of its improved thermal stability. Radici plans to release new long-chain nylons, including 100% biobased grades, in the next year.

NatureWorks LLC and Altuglas International Resins featured the latter’s new Plexiglas Rnew acrylic alloys incorporating 25% to 60% of NatureWorks’ Ingeo PLA (plexiglas.com/rnew). They are said to offer some key improvements over straight PMMA (see Close Up in April). Research scientist Bob Barsotti at Arkema Group, Altuglas’ parent company, cited significantly enhanced melt flow and chemical and impact resistance. Initially, Altuglas is targeting point-of-purchase displays and retail and outdoor signage. Frank Diodato, business manager of durables at NatureWorks (natureworksllc.com), sees

application possibilities where typical PMMA cannot be used and the ability to compete with engineered resins in small and large appliances, housewares and other consumer durables, optical and medical products, building and construction, and automotive components.

SABIC Innovative Plastics (sabic-ip.com) showcased what’s said to be the first use of "upcycled" PCR material on a North American heavy-duty truck. SABIC’s Valox iQ PBT, which is based partly on chemicals from depolymerized PET water bottles, is used in the brackets of the side air-deflection system for all seven models of the 2012 Volvo heavy-duty truck platform. SABIC also displayed the new Canon

Electronics scanner, which utilizes Xenoy iQ ENH PC/PBT, in which the PBT portion also has PET-derived PCR content.

Styrolution (styrolution.com) launched what is claimed to be the first post-consumer recycled line of PS resins. Three grades, each with 25% PCR content, featured in the new Styrolution PCR line are injection molding grades PCR3125 (based on a 3100 GPPS) and PCR5625 (based on a 5600 HIPS); as well as

extrusion grade PCR6225 (based on a 6200 HIPS).

NEWS IN STYRENICS

Styrolution also featured a new, cost-effective HIPS for food packaging. PS6220 is designed to be blended with GPPS to customize toughness and stiffness. It also simplifies extrusion, since its high gloss can eliminate the need for a coextruded gloss layer.

New BX11012, the latest addition to Styrolution’s Luran S ASA weatherable polymers, is formulated for low-gloss extrusion applications that require higher flow than typical extrusion-grade ASA. Excellent impact strength and weather resistance are cited, suiting it to decking, fencing, and siding.

TN 100306, Styrolution’s newest Terluran ABS grade, is formulated for a Vicat temperature of 102 C for applications requiring higher heat resistance than most general-purpose ABS can handle. It’s for auto interior door trim, consoles, and seat trim as well as exterior applications such as pillar garnishes and mirrors.

OTHER NEWS

After two major acquisitions of the PET businesses of Eastman Chemical and Wellman, DAK Americas is developing a new portfolio for key markets, including carbonated soft drinks, hot-fill, water bottles and thermoforming. New product developments under way include new bottle resins with up to 15% PCR

content. DAK (dakamericas.com) also is developing extrusion blow molding grades of PET that have very high I.V. but maintain tensile and impact properties in order to compete with HDPE or multilayer HDPE/PP handleware in large detergent, personal-care, and juice bottles. DAK plans to test market PET resins with biobased content in the next two months.

PolyOne showcased a new and reportedly unique, UL-certified Geon rigid vinyl extrusion grade for electrical applications. It’s the result of the company’s work with sheet extruder Walton Plastics (Walton Hills, Ohio) and its customer, Midwest Plastic Fabricators (Aurora, Ohio). They were looking for rigid vinyl sheet to replace steel in outdoor electrical boxes such as control cabinets, junction boxes, and radio-frequency meters. The final formulation met requirements for processability, flame retardancy,

weatherability, and water-penetration resistance, as well as UL 746C(f1) certification.

SABIC Innovative Plastics launched four new additions to its Lexan PC portfolio. Lexan CFR (clear FR) copolymer for consumer electronics and appliances is a halogen-free grade that meets UL 94V-0 down to 1.0 mm thickness and UL 94-5VA at 3.0 mm. Three new Lexan LUX grades—2110T, 2010T, and 2910T—are designed for LED light guides and lenses. They utilize new technology that improves initial color, color stability, and light transmission during heat aging vs. standard PC. They retain 98% of initial light transmission when exposed to 130 C for more than 5000 hr and do even better at typical exposures of 90 C to 110 C.

Additional new entries from Asahi Kasei Plastics include Xytron PV grades of modified PPE for solar-panel components. They carry UL 94V-0 and 5VA certifications (one meets 5VA at 2 mm) using nonhalogenated flame retardants. Also new is the Tenac Z-Series of acetal grades with low formaldehyde emissions. They are said to exceed the most stringent global automotive specs for VOCs.

BASF highlighted its new Ultrason P 3010 polyphenylsulfone (PPSU), which boasts a combination of high melting temperature, low water absorption, and impact and flame resistance. It’s aimed at dental, surgical, and orthopedic instruments and sterilization components, as well as aerospace interior parts and plumbing fittings.

Nippon Goshei (nichigo.co.jp), represented in the Americas by Soarus LLC (soarus.com), launched what is said to be the first EVOH/nanoclay composite, the result of a licensing agreement with Spain’s Nanobiomatters Industries (nanobiomatters.com). Nippon Gohsei has exclusive use of Nanobiomatters’ O2Block Barrier nanoclay additive in EVOH composites. NC7003, the first in the new Soarnol NC series, is said to offer a notable improvement in barrier properties under high humidity, but with the same

processability and film properties as standard EVOH.

A.Schulman launched patented Polytrope STR cap resins for improving the appearance and physical performance of exterior applications ranging from agricultural, RV, and automotive to watercraft and lawn/garden equipment. The patent covers a coextruded multilayer product that provides a paint-free plastic sheet structure that can simulate the appearance of painted metal or plastic. Each cap resin can be coextruded with a Polytrope STR TPO ranging in stiffness from 250,000 to 600,000 psi flex modulus.

New purging compounds include Purgex 602 Plus from Neutrex Inc. (neutrex.com), a ready-to-use blend of nontoxic, nonabrasive ingredients in a PS carrier that is designed for rapid changeovers from colored to clear PC, PS, and their copolymers processed at 360 F to 550 F. It offers dual-cleaning action, with mechanical cleaning properties plus a unique expanding foam turbulence.

New mechanical, non-abrasive Dyna-Purge E2 was highlighted by Shuman Plastics Inc. (dynapurge.com) with results from recent trials at injection molder Fam-Lee Products Inc. (Loveland,

Colo.). That processor purges as often as 10 times a day and was challenged with changeovers from black or colored nylons to a lower-temperature resin, such as white ABS. Use of Dyna-Purge E2 required only half as much purging compound.

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreRead Next

Materials & Additives at NPE: Performance, Processability, And Sustainability

Bioplastics take center stage.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More