Medical Tubing Coextrusion Brings A New Level of Care

Coextrusion is on the increase in tubing for medical uses, with more layers, more exotic materials, and much thinner walls. These require unprecedented levels of dimensional accuracy and flaw detection.

Highly specialized medical tubing has always involved weird and wonderful feats of miniaturization and complexity. But until recently, the tricks of making micro tubing were largely a matter of artistry—based more on specialized experience and extrusion know-how than on precisely defined die, sensor, or downstream technology.

Indeed, tubing dies have typically been among the least sophisticated used in extrusion. Often they are relatively basic in-line monolayer dies with spider legs inside. Processors also frequently do without any downstream calibration: The tiny flexible tubes of PVC or polyurethane, which remain sticky even when cool, often dangle freely in a cooling trough supported only by internal air pressure.

Some of the tiniest and most complex tubes have been made with relatively simple techniques. Tubes reinforced with wire or fibers and containing tiny hollow channels or lumens blown with micro air jets, have been made for years in a series of extrusion and coating steps that allow processors to stop and check the product after each step.

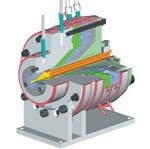

For example, Putnam Plastics Corp. in Dayville, Conn., makes a dual-lumen tube in which one lumen is wire-reinforced (see photo), and the other not. The sequence or steps begins with extruding over a metal mandrel, then braiding over the tube with flat wire. Then the tube is coated a second time, and a profile with a second lumen is extruded over the tube (which would collapse if it weren't reinforced). The final outside diameter is 0.079 in. ±0.002 in.

Tolerances on this and other equally complex tubes have been maintained for years by monitoring the OD and checking samples off-line after each step. Even when processors create bump tubing and tapered tubes using computer-controlled pulling sequences, tapers are typically checked only for OD and only at the smaller end.

"Now people are trying to get tolerances tighter," says Dave Norquist, extrusion sales manager for the Americas at gauging supplier Beta LaserMike. "Five years ago, tolerances were ±0.003-0.004 in. Now they're 0.001 in."

Driving this change is a growing trend to coextruded tubing, which can't be monitored from the OD alone, plus a new, more extreme level of miniaturization. Consider Putnam's latest wire-reinforced tube, exhibited at the MD&M West show last month in Anaheim, Calif. It has an OD of 0.022 in. and a wire spiral encapsulated in a 0.003-in. wall. It's made with tolerances of ±0.0005 in.

Lots more coex to come

Both in Europe and in the U.S., makers of dies and extruders say that last year they shipped noticeably more coextrusion equipment. "We supplied 10 three- and five-layer dies last year," says Paul Hendess, director of technology at die maker Genca. Competitor Guill Tool & Engineering built its first five-layer coex die for medical tubing last year.

Hendess sees the number of coex die builds going up dramatically this year. Half the coex dies Genca sold in 2000 were for commercial production and half for new-product development, including replacements for monolayer flexible PVC and tubes using exotic resins like PEEK, PTFE, and PVdF.

Coextruded tubing structures are also growing more elaborate. A seven-layer tube is being developed for an angiographic balloon catheter by a medical-device OEM.

An increase in medical coextrusion was also the reason Milacron Inc. bought Akron Extruders last year. The purchase adds Akron's line of small (0.75- to 2-in.), pedestal-mounted coextruders to Milacron's single-screw line.

Sequential coextrusion of different durometers within the same layer of tubing adds another level of complexity. Putnam first commercialized this technology over a decade ago. Two years ago, Putnam for the first time combined dual-durometer sequential extrusion with coextrusion of two- and three-layer catheter tubing.

Equipment maker Harrel Inc. recently patented a method of alternating polymers or durometers using two gear pumps in tandem. One pump slows as the other speeds up during the material switchover.

Most coextrusion of medical tubes, both for production and R&D, has been done by medical-device OEMs. "Some OEMs have come up with multi-layer structures to replace PVC," notes Robert Hill, sales manager at Davis-Standard Ltd. in the U.K.

"PVC replacement is happening, but not to the extent that the industry anticipated two years ago," cautions Ray Hackney, president of Duall Plastics in Athol, Mass., a company that was recently acquired by Bunzl Ltd. in the U.K. Charles Sparacino, system sales engineer at Davis-Standard in the U.S., says sales of extruders for PVC tubing have returned to normal levels after dropping sharply three years ago.

Rather than eliminating PVC outright, some new coex tubing merely reduces the amount of PVC used by sandwiching it between other materials. This gets the benefit of PVC's low cost and high strength, but avoids the sensitive question of direct contact by PVC with the body or fluids entering the body.

Custom processors are less involved in coextrusion than are OEMs. Most custom extruders run some coex jobs, but rarely more than two or three layers at a time. A five-layer tube could be a monolayer tube with two coextrusions over it. A five-layer die is much more expensive than a series of simpler coating dies, especially as custom processors may produce only one or two production runs of a new tube if it doesn't make it to commercial production. And even if a new tube does take off commercially, the OEM then may bring production in house. So either way, the product cycle for custom processors can be short, and they have to recoup die and tooling costs up front.

Multi-layer, multi-lumen

Multiple lumens are appearing in thin coextrusions. One of the first processors to do this was Putnam, which builds its own dies. Five years ago, Putnam commercialized a nylon tube with two lumens, one lined with polyethylene to reduce the coefficient of friction without sacrificing tensile strength.

Davis-Standard in the U.K. delivered two coex lines in Europe that include individual air control of multiple lumens. A two-layer, two-lumen TPU tubing line went to a medical OEM in 1998 and is now in commercial production in the Far East. And a three-layer, five-lumen line went to a medical-device OEM last year for product development.

Die developments

With more layers, the task of maintaining concentricity grows more complicated. Genca included a new tip-centering feature in a three-layer die built last year. The firm is applying for a patent on the device, called a Ball Adjusting Tip (BAT). A ball swivel is fixed in the middle of the die bushing, which is also fixed. The moving member works like a pool cue. Adjustments are made from the back of the die to center the tip, which is on the ball swivel near the discharge opening.

Guill also has a patent-pending "swivel-ball" die adjustment via a ball in a socket. The die opening is inside the hollow of the ball, which is adjusted with four screws.

An unusual, patent-pending Rotary Die Head from Guill is being tested now for medical tubing. The tip and die rotate either together or independently to provide more even resin flow, greater wall strength, and—if desired—spiral stripes. A half-dozen of these rotary dies are in use, including one making a three-layer, three-lumen medical tube with 0.062-in. OD.

Guill also received a patent last year on a new "balanced-flow" spiral die for medical tubing.

The past year or two have seen increasing use of spiral-manifold dies for both mono- and multi-layer tubing. Spiral manifolds eliminate spider knit lines, which are potential weak points in the tubing wall.

Last year, Genca built three 1-in. dies with spiral manifolds to coextrude a nylon outer layer, flexible PVC core, and LLDPE inner surface. The layers are thermally isolated, so the high-temperature nylon won't degrade the thermally sensitive PVC. This die comes in three sizes from 0.5-in. to 2-in. max. die opening.

Davis-Standard says it is building more side-fed spiral dies than in the past to accommodate air feeds for increasing numbers of lumens. Boston Scientific Corp. in Natick, Mass., and Dunn Industries Inc. in Manchester, N.H., have made products with up to 12 lumens. Putnam has made a 13-lumen tube for fiber optics and probably holds the record with a 21- lumen tube made five years ago.

On the other hand, spiral-manifold dies have the disadvantage that they must be taken apart more often for cleaning, and cleaning them is inherently more difficult. Consequently, Genca has developed a new curved spider leg that reportedly improves knit lines in rigid PVC. It will become commercially available later this year.

Harrel, a builder of extruders for medical tubing, aims to remedy the spider knit-line problem with its Spirodie, developed three years ago. Harrel puts mixing spirals after the spider in order to recombine the flow. This adds about 1.5 in. to die length.

Tightening tolerances

It's not just tubing dies that are getting more sophisticated. So are extruder drives, calibrators, and pullers. American Kuhne last year built its first extruder with a servo drive. It was a 1-in. model for small, very precise medical tubing. Servo drives have been used more often for highly precise pullers and cutters than for extruders. "The price of servo drives has come down, and this customer wanted the best," says Ed Steward, director of process technology at American Kuhne. "If you're running a small extruder below 10 rpm, you have more accuracy in maintaining screw speed with a servo than with an AC drive."

As for more sophisticated downstream equipment, Conair in Pittsburgh says sales of its vacuum sizing tanks with upgraded digital controls grew 25% last year. "A lot of medical-extrusion people are moving away from free-extrusion tanks to vacuum tanks," says Conair v.p. of extrusion Ernie Preiato. "They may have been struggling to hold a tolerance of ±0.002 in., but with a vacuum tank they can hold ±0.0005 in."

Vacuum sizing was used recently by Pexco Inc. in Northboro, Mass., to make an unusual three-lumen PVC tube for blood warming. The lumens aren't tiny channels, but thin-walled compartments roughly equal in size and difficult to extrude without deforming. In this product, Pexco maintains three different wall thicknesses: an outer wall of 0.0036 in., an inner wall of 0.0013 in., and two 0.0017-in. supporting webs in between.

In the past two years, both Davis-Standard's Killion Div. and R.D.N. Manufacturing Co. developed computer software to control the OD profile on taper tubing by interpolating between specified points. With this software, an operator can maintain the same taper profile while changing the overall size of the tubing. The operator just changes a single OD point, and the program calculates the new puller speed and air pressure automatically.

Davis-Standard Killion has also sold over a dozen cutters in the past two years that are said to be the only ones available to cut different lengths of corrugated respirator tubing accurately. The system uses a photo-eye to spot the cutoff point at the flat cuff on the tube where the convolutes stop. The unit cuts at 100 ft/min line speed, says Killion downstream sales engineer Glen Beasley. "Absolutely no one else can do this," he claims.

Medical-tubing makers are also putting more emphasis on gauging for quality control. Medical Extrusion Technologies in Murrietta, Calif., coextruded a three-layer tube with one lumen using ultrasonic sensors from On Line Controls in the water bath to verify concentricity of the layers. Lumens generally interfere with ultrasonic gauging of layer thicknesses, but the problem can be overcome in a single-lumen tube, Medical Extrusion says.

What about sensing the position of the lumen itself? "The wall thickness from the outer surface of the tube to the lumen can be measured under certain circumstances, provided the signal evaluation is sophisticated," says Ernest Henzi, senior v.p. of marketing at Zumbach Electronics. The system must be able to distinguish the energy reflected by the outer wall of the tube from echos reflected by the density change at the lumen. If you can isolate the second signal, you can identify the inner wall of the lumen, he explains. "The success of this method depends on the geometry and position stability of the lumen." If the tube twists, it won't work.

As tubes get smaller and walls and layers get thinner, some products have dropped below the horizon where no current sensors can pick them up. Medical Extrusion has made a soft polyurethane tube to deliver drugs to the brain that has an 0.003-in. OD and a wall thickness of just 0.0003 in. And Guill Tool recently ran a successful trial of a fluoropolymer tube with 0.010-in. OD and walls only 0.0002-in. thick.

Gauging suppliers are struggling to keep up. The Ultragage 4000 ultrasonic sensor, introduced by On Line Controls at NPE 2000 in Chicago last June, controls wall- thickness down to 0.0005 in. And a new ultrasonic gauge introduced by Zumbach at the MD&M show in Anaheim, Calif., last month measures walls down to 0.0008 in.

Thin coextruded layers may also be too fine to detect. "It has put a major burden on makers of wall thickness monitoring devices. They're having to get their sensors closer to the tube and to do more scans," says Davis-Standard's Sparacino.

Zumbach and Beta LaserMike both recently introduced flaw detectors for gels and surface defects in medical tubes. Gel detection is common in wire and cable and in film extrusion, but new for medical tubing. Previous scanners looked only for surface imperfections.

There is now finally a way to measure diameter along the length of a taper. Beta LaserMike launched a new Taper System at the MD&M show last month with new programming that monitors a continuous taper. The company also has new software that allows a high-speed scanning laser to monitor multiple strands from a single gauge.

Going for higher output

Another change in the past two or three years is that makers of critical tubing like catheters are raising output rates. "The standard machine for I.V. tubing had been 2.5-in. diameter, 24:1 L/D," says Davis-Standard's Sparacino. "Now the accepted standard is 3.5-in., 24:1."

The larger machine roughly doubles line speed from 100-150 ft/min of tubing to 200-300 ft/min. "That's about the maximum for catheter production now, and there aren't many people going that fast," notes Holton Harris, president of Harrel.

Raising outputs requires more rugged extruders. Merritt Davis Corp. in Hamden, Conn., just introduced the new Millenium Series 1.5-in. extruder for medical tubing, which offers an optional rigid H-frame on the portable coextrusion models. And Davis-Standard's Corporate Extruder series, introduced last year, also has a heavier base and more rigid frame.

Davis-Standard's Killion Div. last year developed a "hands-free" feeding technique that captures soft, ultra-thin silicone tubing as small as 0.0032-in. OD and feeds it automatically into the puller/cutter on start-up. The die bushing has a trumpet-shaped inlet that delivers tubing to the pinch point of the puller. Otherwise, manually feeding such soft, droopy tubing to a puller/cutter wastes a lot of expensive product at the start of a run.

Related Content

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More