Medical-Tubing Innovator Bets on Silicone Solutions

Trelleborg gains footprint in silicone-based implantable medical extrusions.

For more than 100 years, and around the world, Trelleborg has provided an extremely diverse range of products that seal, damp, and protect highly demanding applications in aerospace, automotive, oil and gas, mass transit, marine equipment, construction, and more. They even make tires and wheels for industrial, construction, and agricultural vehicles. The Trelleborg Group has operations in 50 countries with annual sales in excess of $3.6 billion.

Talk about a powerhouse.

Headquartered in Sweden, Trelleborg has been doing business in the U.S. for decades, with Trelleborg Sealing Solutions for the Americas based in Fort Wayne, Ind. But until last June, the company had a limited presence in key areas of the high-growth health care and medical market in the Americas. So Trelleborg went out and bought privately held, family-owned Specialty Silicone Fabricators (SSF).

“Trelleborg Sealing Solutions has been in the medical market for many years but our offering, though at the forefront of technology, was primarily for healthcare equipment,” explains Drew Rogers, global director, Healthcare and Medical for Trelleborg Sealing Solutions.

“The acquisition of SSF allowed us to bring into our portfolio solutions that could be implanted into a patient, enhancing our already established global offering,” adds Rogers. “Trelleborg has now broadened its capabilities to tap into a growing industry.” Trelleborg’s medical and healthcare operations in the Americas are focused on silicone—with both LSR and HCR capacity—and form part of a global network for extruded and molded products in its other markets.

Trelleborg’s third medical manufacturing plant is in Elk Grove, Mich. At this site, dip coating operations are used to produce minimally invasive surgical instruments.

The acquisition of SSF enhanced Trelleborg’s capabilities with what Rogers describes as “a clearly differentiated product line.” He elaborates, “The implantable footprint is really the major step that Trelleborg has taken. SSF had a long history and a lot of expertise in implantable devices; 60% of what we manufacture are implantables.”

Trelleborg’s healthcare and medical segment is supported by various plants located across the world. Through the SSF acquisition, Trelleborg gained three additional manufacturing facilities. One is in Paso Robles, Calif., a 102,000-ft2 plant that is ISO 9001 and 13485 certified and houses ISO 8 and ISO 7 cleanrooms. Trelleborg does a majority of its medical parts processing in Paso Robles, with an undisclosed number of extrusion lines for tubing and sheet.

Trelleborg’s second facility dedicated to medical is in Tustin, Calif., and is registered with the Food and Drug Administration (FDA) as a finished medical-device manufacturer. Also ISO 13485 certified, this 55,000-ft2 plant has ISO Class 8 and Class 7 cleanrooms. In Tustin, the company does product assembly, packaging, sterilization and drug-device work; the Tustin facility is licensed to work with active pharmaceutical ingredients (API), meaning that it can produce tubing that elutes anti-microbial agents, for example.

CUTTING ITS TEETH IN EXTRUSION

The majority of what the company makes in Paso Robles are custom components. On the tubing side, they can range from a few hundred feet to several thousand. About half of what the company extrudes is coiled, the other half cut to length. Tubing extrusion equipment is moved around to accommodate other production processes as needed.

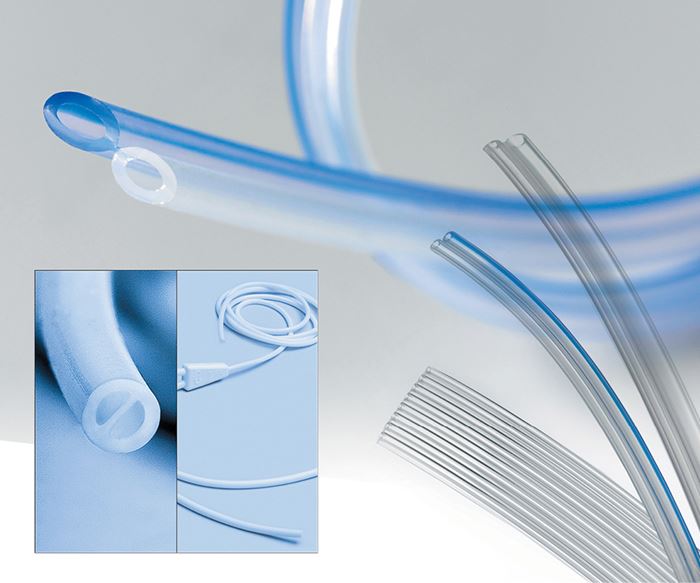

“But extrusion is our differentiator,” states Rogers. “Extrusion is where we cut our teeth.” Trelleborg offers high-precision, tight tolerance silicone extrusion tubes in wall thickness of 0.004 in. at excruciatingly tight tolerances of ±0.001 in.

About 10 years ago, the company developed its own extrusion tooling process, called GeoTrans (short for geometric transition). In this technology, components within the die can be moved on the fly to change tubing geometry, to transition from single to multiple lumens, or even to split a single tube into two in a “Y” shapes. The technology eliminates secondary assembly steps.

GeoTrans technology is used on Trelleborg’s balloon catheters, bump and tapered tubes. It is also deployed on what the processor calls its Material Transition tubes, in which one silicone material transitions to another over the length of the tube, where different mechanical properties, additives, color, opacity, radiopacity, and durometer are required. A typical application for this technology would be a catheter that has a soft tip for patient comfort but is otherwise stiff, making it easier to be placed where it belongs in the patient’s body.

Trelleborg is also on the cutting edge of technology that uses its silicone-based devices or parts as a vehicle to deliver drugs. “We have a lot of experience in this area, and it’s a segment of the medical market that is growing very quickly,” says Rogers. “We’ve been working with API for antimicrobials but with hormones for contraception and devices that include medicines for sexually transmitted diseases. We’ve worked on a molded silicone implant that elutes a drug specifically for malaria-infested populations. In this case the drug that elutes kills not only the diseases but the mosquitos too.”

Combining silicone products with an API provides a variety of benefits. For one, it can permit a more controlled release rate of the medicine. Secondly, it allows for a more targeted delivery of the API. Explains Rogers, “Cancer drugs are often taken by pill or injection. Of course these are very strong medicines that, when delivered this systemically, travel through the entire system. The result is many well-known and undesirable side effects, including tissue degeneration. With an implant delivery device, you can deliver a drug right at the point of the tumor, using a drug reservoir and release control or a patch. Generally speaking, a drug/ device combination product may be a part already going into a patient: a wound-drain catheter, for example. Impregnating the antimicrobial into the wound-drain tube itself turns that tube into a solution as opposed to a culprit (for infection).”

Silcone products and drugs can be combined in one of three ways, Rogers explains. In one scenario, raw silicone and a powdered form of a drug are mixed prior to fabrication. The drawback of this technique, Rogers notes, is that silicone is typically cured at high temperatures, and the extreme heat can affect the efficacy of the medicine.

In the second approach, a silicone part like a tube is immersed into a liquid form of the drug or a drug in solution for a very specific period of time. States Rogers, “In addition to being biologically inert, the great thing about silicone is that it has very consistent absorption and elution characteristics. So if you take a particular durometer of silicone and immerse it into a particular concentration of a drug for a particular amount of time, it will always absorb the same amount of drug and once implanted will always elute at the same rate. You can get a very consistent effect.” Most of the time, Trelleborg develops an application- specific drug-device combination to meet the customer’s elution specifications. These formulas, as Rogers puts it, are both “precise and precious.”

The third way silicone and APIs are mixed is by producing small, proprietary drug-delivery reservoirs, used in conjunction with a vaginal ring. This approach is being widely embraced in women’s health on a global scale.

WHY JUST SILICONE?

States Rogers, “We are experts in material selection and recipe formulation for the particular solution. If, for example, the tube has to be firm when inserted into the body but be able to be twisted when it’s inserted, we can develop a recipe to that spec.

We can help with material selection and process development to accommodate those performance characteristics.”

Rogers continues: “There are other benefits silicone brings to the table in medical. Once it’s cured, the shape will not change. It can be sterilized in any method. Thin silicone sheets can be gas permeable. Of course, not every application requires this. If you just want a good hard tube to run from an oxygen tank to a mask, you probably don’t need silicone. We don’t push anyone to silicone unless it’s the right solution.

“We also think of ourselves as a safe haven for start-up companies who come to us with an idea and a picture and who want to ensure they will pass regulatory or not experience a shutdown due to FDA findings down the road.”

Related Content

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreCustom Molder Pivots When States Squelch Thriving Single-Use Bottle Business

Currier Plastics had a major stake in small hotel amenity bottles until state legislators banned them. Here’s how Currier adapted to that challenge.

Read MoreDuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More