Milacron Broadens Kortec Co-Injection Offering

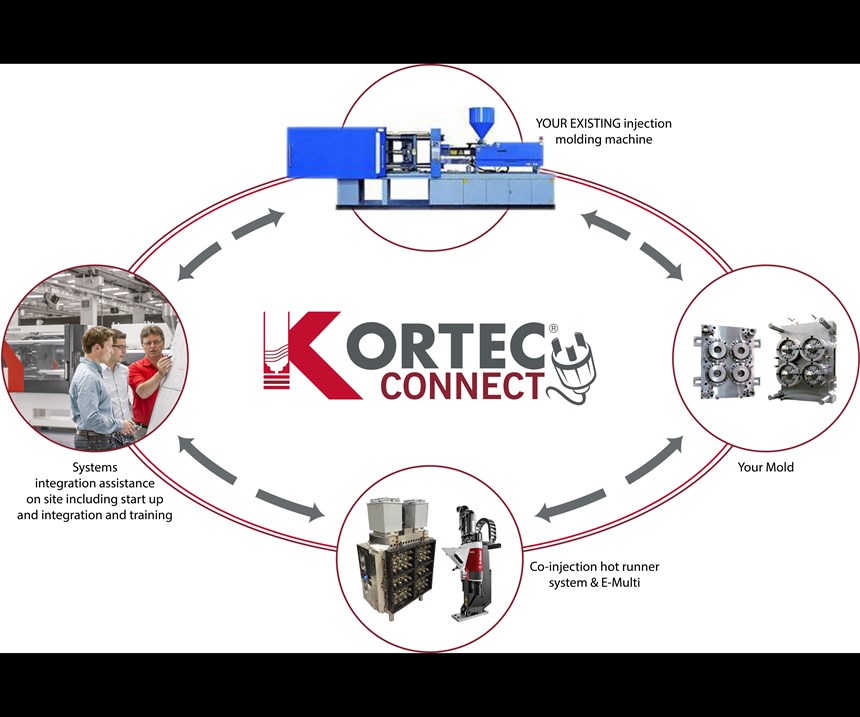

Now there’s a way to take advantage of Milacron’s Kortec co-injection technology using your standard injection machine.

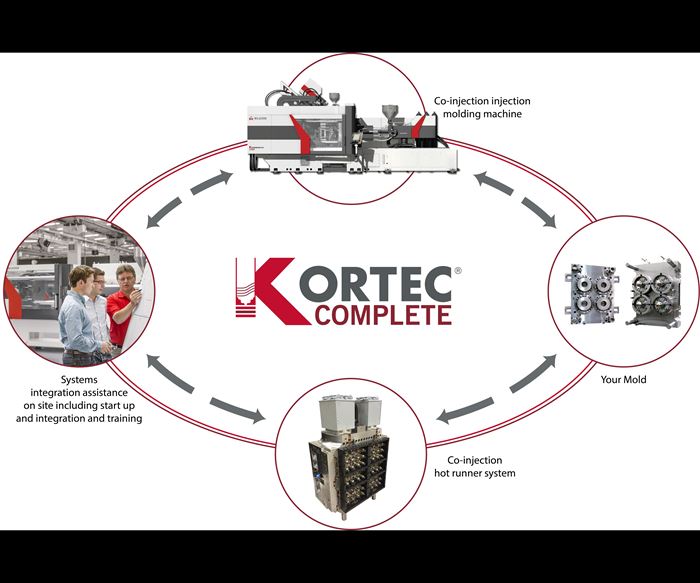

Milacron Holdings Corp., Cincinnati, is introducing a new way to take advantage of its Kortec co-injection technology for products needing a three-layer barrier sandwich structure. Up to now, Milacron has offered turnkey systems (now branded Kortec Complete) consisting of a two-component injection machine, Kortec hot runner and engineering support—including integration assistance, startup, and training. Now, molders who wish to use an existing injection machine can choose the new Kortec Connect package, which comprises a Kortec hot runner, Mold-Masters E-Multi secondary injection unit as an add-on for the existing press, and the same engineering support.

Milacron claims 30 years of experience in co-injection, with over 100 systems in the field, producing 12 billion parts in 18 countries. Kortec Connect will be featured at NPE2018 May 7-11 in Orlando, Fla., at booth W2703.

Related Content

-

Coinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.

-

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

-

Milacron’s Massive Booth Highlights Multiple Brands

NPE2024: Coinjection of postconsumer resin, in-mold decoration, LSR micromolding and bioplastics processing are just some of the machine displays at Milacron's booth.