New Engineering Materials for Challenging Automotive Applications

Nylons, PPA, and PPS for high heat and chemical resistance and/or high strength with light weight.

Two units of Solvay (U.S. office in Alpharetta, Ga.) have introduced several new engineering materials for demanding automotive applications requiring high heat resistance, chemical resistance, and superior strength with light weight.

NYLONS FOR THERMAL MANAGEMENT

Solvay Performance Polyamides introduced two new Technyl nylon products for automotive thermal management. One is Technyl Blue D 218CR V33, a nylon 66/610 copolymer that features very high hydrolysis resistance plus high resistance to road salts. Main immediate applications are radiator end tanks, oil-filter housings, and exhaust-gas recirculation (EGR) heat exchangers. This product has been grouped together with two existing series of Technyl nylon 66 products in the Technyl Blue family with three levels of performance. The new grade has “very high hydrolysis resistance”; below it are the Technyl Blue G2 grades (“high hydrolysis resistance”) and Technyl Blue 34NG grades (“hydrolysis resistant”) in a range of glass contents.

All three reportedly offer thermal-aging resistance in presence of aggressive coolants (hot water/glycol mix). Technyl Blue 34NG reportedly shows 15% higher tensile-strength retention than standard nylon 66 after 1000 hr at 130 C/266 F. Technyl Blue G2 raises that to 30% greater strength retention; and the new D 218CR V33 grades provide 60% greater tensile-strength retention than standard nylon 66. All three are said to offer high flow and excellent surface quality, relative to competing specialty polymers.

New nylons fight off attack from road salt and glycol coolants.

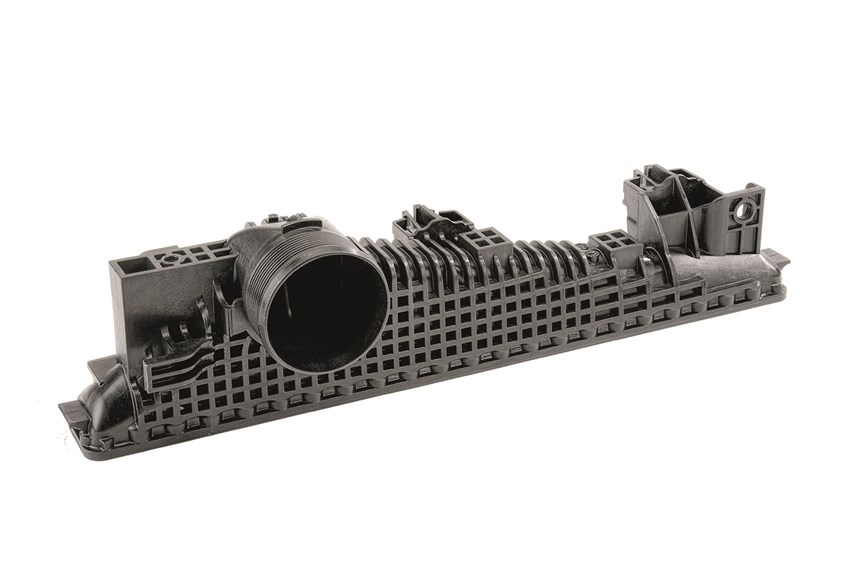

The second new product from Solvay Performance Products is Technyl Red S, a nylon 666 that is highly heat stabilized for continuous use at 200 C/392 F. It is aimed at turbo engine air ducts and charge-air coolers, as well as cylinderhead covers. It is said to be an advance over the established Technyl HP grade.

Technyl Red S has been tested at 200 C for 2000 hr and at 210 C/410 F for 1000 hr. It also boasts high resistance to impact and to acid condensates, as well as high flow, superior surface quality, and excellent weldability.

MORE SPECIALTY ENGINEERING GRADES

Meanwhile, Solvay Specialty Polymers also has fielded several new materials for specialized applications. Solvay added more automotive thermal-management materials with new Ryton R-4-300 PPS with 30% glass and Amodel A-89XX series of polyphthalamide (PPA) resins with 30-50% glass.

The new Ryton grade is a linear PPS with improved tensile strength and elongation, as well as “best-in-class” weld-line strength. The new PPAs are for underhood components such as thermostat housings, multi-coolant valves, and water inlets/outlets and crossovers.

Also new is orange-colored Ixef 1524 polyarylamide (PARA, also known as MXD6 nylon), a halogen-free flame-retardant grade with 50% glass fiber for electric-vehicle recharge connectors. It is color matched to “signal orange” for this application.

Despite high glass content, it reportedly shows high flow for walls as thin as 0.5 mm, supporting high injection speeds and short cycles. It offers a balance of high stiffness and toughness, as well as a glossy, resin-rich surface. It also meets UL 94V-0 at 0.4 mm.

Another new Ixef PARA grade is black Ixef 3012, containing 55% carbon and glass fibers. It was developed to offer extremely high strength and stiffness at low weight, along with “exceptional” surface finish. Its high flow allows molding long, thin parts that need no painting for automotive, aerospace, and consumer applications.

Additional properties include electrical conductivity and high creep resistance. Applications could include auto air-vent lamellas and throttle-body levers, drone components, and action-camera fixation parts and cantilever snaps.

Related Content

Custom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreNovel ‘Clamtainer’ Extends Thermoformer's Reach in Packaging

Uniquely secure latching expands applications for Jamestown Plastics’ patented clamshell package design.

Read MoreNew CRM Streamlines Quoting for Automotive Molder

Eliminating the need to contact each supplier for every individual quote, a new CRM for automotive supplier Axiom Group tracks past quotes as well as industry history to generate fast, reliable RFQs and more.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More