New Machinery and Processes for Thermosets, LSR Foam and Moldable Leather

A new small vertical press for insert molding and a new BMC stuffer were rolled out by Arburg GmbH + Co.

A new small vertical press for insert molding and a new BMC stuffer were rolled out by Arburg GmbH + Co. KG, Lossburg, Germany, at its annual Technology Days conference and technical exhibition. Meanwhile, Arburg together with industry partners showed two interesting process developments—a new technology that pairs scrap leather and resin to make injection molded leather parts, and updated information on a novel LSR foam molding process.

Equipment advances

Arburg provided more details on the Allrounder 275 V vertical-clamp unit that was first introduced at last October’s Fakuma show in Germany. The new unit extends Arburg’s vertical hydraulic C-clamp line with a clamp force of 27.5 tons and a fixed or rotary table. The press has an opening stroke of 225 mm and daylight of 475 mm. Its upper platen handles mold weight up to 143 lb. A choice of two injection units offers three screw diameters from 18 to 30 mm. Shot capacity is from 21 to 65 g PS.

Arburg also unveiled a new screw feeder/stuffer for glass-reinforced polyester thermoset bulk molding compound (BMC). The device has a new feed-pressure control that allows it to convey BMC compounds more efficiently than a conventional piston.

New processes presented

Bader GmbH & Co., Goppingen, Germany (represented here by Bader USA), a supplier of leather components for automotive interiors and the largest maker of leather-clad car gearshift handles in Europe, has found a new use for leather scraps not suitable for prime auto applications. Bader usually sells the scrap leather to processors in Pakistan or Asian countries that make wallets, handbags, and other accessories.

Five years ago, Bader created Kollamat, a subsidiary that compounds leather scrap with resin. Bader is now marketing the material (also called Kollamat) commercially. The plastic/leather compound may find use as a replacement for vinyl in auto interiors or for toys. The plastic/leather mixture absorbs moisture and has a soft leather-like feel and appearance, notes Alexander Stoll, director of the Kollamat business.

To produce the Kollamat, the leather is chopped and shredded into fiber. Bader adds chemical agents that remove up to 80% of the moisture and retard aging. A special process is used to compound the leather, resin, color, and additives into moldable pellets. Stoll says the material can be foamed.

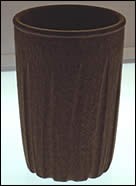

Stoll showed off a 100-g injection molded drinking cup made of 60% leather fiber and 40% LDPE. It was molded on a 100-ton Arburg Allrounder C 1000-250 press on a 58-sec cycle. The single-cavity mold required slight modifications. Bader has also produced a shoulder guard made with TPE and 25% leather. “Products can be molded with 10% to 70% leather by weight. The leather can be combined with many different polymers, including TPE, EVA, PVC, LDPE, PS, or EPDM,” says Stoll. Usually it can be run with short cycles and low clamping forces.

Leather is best suited for use with polymers that melt in the range of 320 to 338 F, he notes, so PP may be excluded because it processes at around 428 F. Due to its high viscosity, the material is molded currently with a cold runner. Stoll says the leather compound requires more intense mold cooling. Parts experience about 0.5% mold shrinkage. Kollamat has a typical elongation between 5% and 120%, moisture content of 1% to 3%, density from 0.5 to 1.2 g/cc, and tensile strength from 145 to 1450 psi.

Meanwhile, new information is available on the Optifoam LSR injection foaming process unveiled at last year’s Arburg Technology Days (see Learn More). Developed by Sulzer Chemtech in Switzerland, the process has been upgraded with new valves for material dosing and gas loading to improve repeatability. The dosing of the gas used to affect resin metering by causing slight changes in pressure levels, but that has been alleviated. The new valves achieve more exact dosing and hold part-weight variations to less than 0.1% of target, vs. about ±1% before.

The Optifoam technique adds nitrogen or CO2 under 1450 to 2900 psi to both LSR components through metering units connected to each material feed line. Introducing the gas in a “supercritical” state enables it to diffuse fully into the LSR. Optifoam can reduce weight by 30% to 60% and Shore hardness by up to 50%.

Related Content

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreScaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

Read MoreAbsolute Haitian Brings Next Generation of Presses to Orlando

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More