New Pump Helps Resin Producer Gear Up for Higher Productivity

MELT PUMPS

Adding new gear pumps allowed LLDPE producer to boost production by nearly 40% and cut downtime.

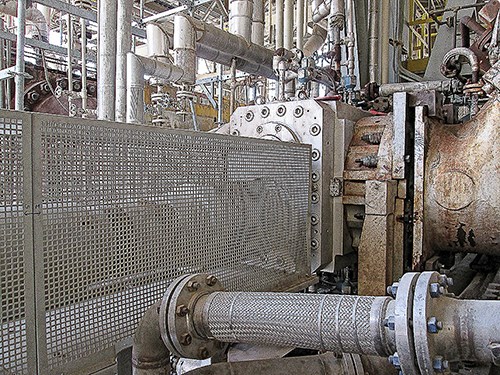

A major Middle Eastern producer of polyolefins realized big gains in production by switching to a specially designed gear pump furnished by Maag Automatik, Inc.. EQUATE Petrochemical Co. in Kuwait was established in 1995 as a joint venture between Petrochemical Industries Company (PIC), Dow Chemical Company, Boubyan Petrochemical Co., and Qurain Petrochemical Industries Co. EQUATE began operating in 1997 and is now considered a worldwide producer of a variety of petrochemicals as well as PE and PP. Its products are marketed throughout the Middle East, Asia, Africa, Europe, and the Americas.

SLIPPING OUT OF GEAR

EQUATE runs two lines at its LLDPE plant in In Kuwait. While output rates were more than adequate, the material supplier believed they could be increased with a gear-pump upgrade, says Mohammad Al-Qahtani, senior technical advisor for polyethylene. “We tried to push those gear pumps more than the design allowed,” he explains. “The result was that we still didn’t get the production rates we wanted and the pumps were more prone to breakdowns and maintenance issues.”

LLDPE must be pumped at high temperatures, and the production rates were limited by the fact that the gear pumps EQUATE was using would experience bearing failures if the temperature reached the highest allowed limit. This limited the pump to a lower LLDPE flow rate, which created a challenge for Al-Qahtani: If he wanted to reach a higher desired flow rate that matched the extruder’s maximum rate, he would have to risk pushing the pumps past their breaking point.

“We want these pumps to run for years without needing to be maintained, but the existing pumps were starting to need maintenance every two to three years due to pump volumetric efficiency lost,” Al-Qahtani notes. “Maintaining the pump was also difficult since the shaft could not be taken out while the pump was in place. To repair it, the pump would need to be taken out of line, a spare pump put in, and the broken pump would be sent to a workshop for repairs, causing serious interruptions in production.”

Faced with insufficient production rates and costly maintenance shutdowns, Al-Qahtani began the search for a solution. His colleagues at Dow Chemical recommended an alternative: the polyrex 32 (PR 32) gear pump from Maag in Switzerland (U.S. office in Charlotte, N.C.).

“We approached Maag to see if we could reach the required production rate while using the same motor,” Al-Qahtani recalls. “We also wanted a drop-in pump that could be customized so that the old pump could be removed and replaced with the new one, a like-to-like pump.”

The PR 32 was able to meet all of Al-Qahtani’s demands because Maag designed it specifically for polyolefins, explains Manfred Waeckerlin, Maag’s director of pumps. It has special gear teeth that have low squeezing power for gentle treatment of polymer melt, along with upgraded shafts and bearings that can easily handle the higher operating temperatures found in LLDPE manufacture and transfer, he says. The PR 32 model offers a flow rate that is higher than the extruder’s maximum rate, which hits the production target that EQUATE was aiming to achieve, according to Waeckerlin.

Since EQUATE was also looking for a pump that could be a drop-in replacement for the existing pumps, the PR 32 models could be built to fully match the existing pump dimensions with no changes required to the system layout or effect on the plant’s operations, Waeckerlin notes. The pumps were also designed so that if maintenance were required, the pump shafts can be pulled one by one directly at the site, without taking the pump out of the production line. This also results in far less production interruption than EQUATE confronted with its previous pumps.

The first PR 32 was put in service in February 2014, with a second going on line in December 2014. According to Al-Qahtani and Waeckerlin, production rates have increased by 39% compared with the previous pump. The units are also said to be running with normal bearing tempera- tures that are well below the preset emergency shutoff point.

Because of the production-rate improvements, EQUATE can now produce more LLDPE that is valued at multi-millions of dollars, while the reduction in maintenance costs and production interruptions will also have positive benefits for the bottom line. Says Al-Qahtani, “Since we’ve put these PR 32 pumps in line we have achieved more than the agreed upon flow rate. The pumps are running in a comfortable state and we expect they will provide many more years of reliable, cost- effective, and safe operations in our LLDPE production.”

Related Content

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MorePart 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More