New System Runs Two Molds in One Press Simultaneously

Shuttle-mold system is one of several eye-popping innovations that Canon Virginia brought to NPE2018.

Canon Virginia Inc., Newport News, brought the wow factor to NPE2018 last month, showcasing not only its custom mold manufacturing capabilities and signature vision systems, but also a new, sleek multimold system, new mold-texturing technology, and a new focus on medical contract manufacturing.

Takashi Arai, v.p. of the company’s Advanced Manufacturing Technology Group, emphasizes the company’s continual pursuit of innovation to provide customers with new and better ways to achieve efficiency in cycle time, mold changeovers and overall productivity.

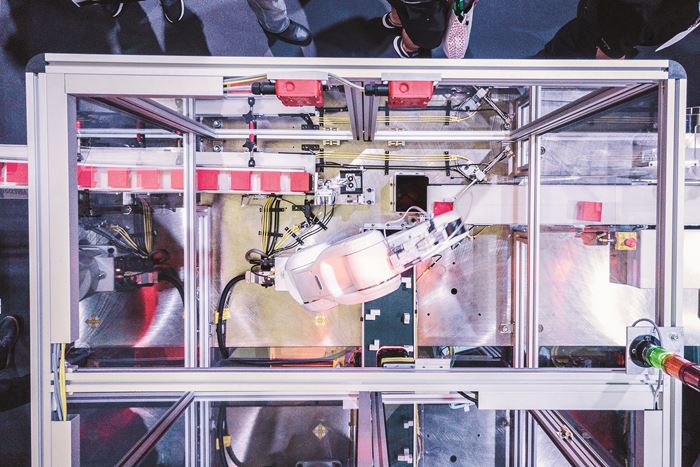

An example is the new multi-mold system, which runs two separate molds in one press simultaneously. NPE attendees saw the system running in a customized Sumitomo press in Canon’s booth.

This is how it works: Plastic is injected into the first mold. The system then moves the first mold outside the machine’s clamping area for cooling and moves the second mold into place for processing. Then the first mold returns into the machine and ejects its parts, while the second mold moves outside of the machine for cooling.

The system incorporates a robot that can handle two types of parts with different shapes. This “mold shuttling” process repeats for the next cycle and so on.

According to Arai, this system helps transform idle cooling time into productive time by shuttling a second mold into production. Technicians can program different process conditions for each mold, like pressure, temperature, injection speed and clamp force as specified for each mold; and the system changes the parameters automatically as the molds shuttle back and forth. The proprietary process accomplishes dual, multi-product molding by the same machine without error or loss of time.

MECHANICAL MOLD TEXTURING

Canon also introduced machined texturing for molds that can replace traditional chemical processes. Arai explained that thanks to proprietary vision technology, Canon machined texturing can reduce lead times compared with chemical processes, and improve mold life and reduce downtime and costs. “This next-generation technology creates product textures that the human eye perceives not as flat surfaces, but as patterns with tactical differentiations based on human sensory response. It creates very precise patterns with delicate features unlike chemical processes that can have wide deviations in texturing,” he said.

Finally, Canon displayed various machine vision systems, including 3D vision, in which the “eye” utilizes cutting-edge optics, image recognition and data processing to achieve three-dimensional recognition of production parts that are randomly piled in a bin and then snaps multiple images to quickly create a 3D image of the part.

EDITOR’S NOTE: Cynthia Kustush is senior editor for Moldmaking Technology Magazine, a sister publication of Plastics Technology.

Related Content

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

How to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.