New TPE Compounder Debuts in U.S.

Formulating thermoplastic elastomers is a highly customized business.

Formulating thermoplastic elastomers is a highly customized business. In its first three months of operation, Kraiburg Corp. in Duluth, Ga. has made some 30 custom products and another 20 standard grades of TPEs based on styrenic block copolymers (SBCs). Of course, it has a long way to go to catch up with its German parent company, Kraiburg TPE GmbH. Since 1984, that firm has made over 6000 varieties of styrenic TPEs alone and has over 10,000 grades in its entire line.

Kraiburg TPE, which has operations in five European countries and Malaysia, became an independent part of the Kraiburg rubber group in 2001. It set up a U.S. sales office in 1999 and started up its first production here in March of this year. The Georgia plant has one Theysohn twin-screw extruder with a capacity of about 3.2 million lb/yr. Kraiburg is gradually ramping up production and is adding to its current staff of 18 in order to expand from two shifts to three.

Heading up the U.S. operation is president Rudi Herbst, who has been with Kraiburg since 1991. Chuck Calhoun, director of sales and marketing, came to Kraiburg from 14 years in sales and product management at Ticona. He foresees adding capacity within the next 18 months to over 10 million lb/yr. Additional equipment will be dedicated to longer runs of standard grades, while the current machine will be used for custom colors and short-run products.

Strong in consumer goods

Kraiburg’s first major success in the U.S. was supplying TPEs used in razor blades. Since then, it has branched out in consumer disposable and non-disposable products such as razor handles and toothbrushes. Other market focuses in the U.S., Calhoun notes, are toys, sporting goods, appliances, electronics (including cell phones), power tools, and auto interiors (e.g., covers for airbags, instrument panels, and steering wheels).

The Georgia operation is making only the Thermolast K line of products, which are based mostly on SEBS, though some are based on SEPS (a specialty SBC from Septon Co. of America). One recent addition, developed jointly with Ti-cona, is the CO Series, which is modified for good adhesion to acetal in two-component molding. Very few plastics adhere to acetal, notes Calhoun. He says the CO Series offers potential in sporting goods, personal hygiene, materials handling, and irrigation applications.

Other products available here as imports from Germany are a TPE-O line based on PP modified with acrylate rubber. These grades are designed for good oil resistance at moderate temperatures. Calhoun says some automotive firms have expressed interest.

He has seen more enthusiastic interest in Kraiburg’s newest product, dubbed E2. This novel TPV (thermo plastic vulcanizate) is based on epoxidized natural rubber in a PP matrix. The rubber is patented by a Kraiburg joint venture in Malaysia and Kraiburg has the exclusive right to use it in compounding. In terms of oil and heat resistance, E2 reportedly fills a gap between thermoset rubbers (EPDM and NBR) and TPVs of EPDM/PP. Oil resistance is said to be comparable to NBR and much better than standard TPVs. Compression set is also lower for E2. According to the ASTM D-2000 standard, E2 reportedly fulfills all the requirements stipulated for NBR and epichlorohydrin rubbers. Current pricing is generally competitive with standard TPVs but is expected to drop as E2 production achieves higher volumes.

Kraiburg has developed E2 grades from 55 to 75 Shore A. Representative properties appear in the accompanying table. Calhoun says customer interest suggests opportunities for this material in automotive and fluid-handling components.

Unusual applications

Two recent success stories with Thermolast K in Europe have potential in this country as well, says Calhoun. One that has attracted some attention in the U.S. is an injection molded keypad for an electronic controller in Germany. It replaces more costly thermoset silicone rubber. This is said to be the first use of a TPE in a keypad. It’s molded of a new transparent Thermolast K compound with a density of just 0.9 g/cc.

Another unusual application is the injection molded back and headrest for an office chair by Vitra of Italy. A 42 Shore A compound is used for the headrest and a 75A grade for the back.

| Properties of E2 TPV | ||

| Shore Hardness Destiny, g/cc Tens. str., Mpa Ultimate Elong., % Tear Str., N/mm 100% Modulus, Mpa 200% Modulus, Mpa | 66 1.08 5.0 275 12 - - | 75 1.08 5.2 345 15 2.6 3.3 |

Related Content

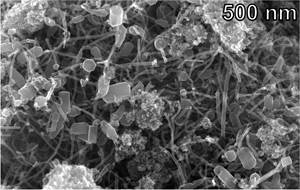

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More