New Welding Technologies Grabbed Spotlight at K Show

Greater use of electric servo drives and new hybrid systems incorporating multiple joining methods were recurring themes among the latest plastics welding and assembly equipment introduced at the recent K 2007 show in Dusseldorf.

Greater use of electric servo drives and new hybrid systems incorporating multiple joining methods were recurring themes among the latest plastics welding and assembly equipment introduced at the recent K 2007 show in Dusseldorf. Among the top innovations were an all-electric vibration welder, a servo-driven infrared welder, a hybrid that does both vibration and infrared welding, and a specially designed ultrasonic welder for cleanroom use.

SERVOS CUT CYCLE TIME

The new model M-624HRSi from Branson Ultrasonics is claimed to be the first all-electric vibration welder. It features an electrically powered lift table that moves at 500 mm/sec, twice the speed of comparable hydraulic lift tables. It dramatically reduces cycle time, energy consumption, and noise, Branson claims.

This is reportedly the first linear vibration welder to incorporate infrared preheating. An upper tool-change system with electric screwdrivers permits a tool change within 1 min. A self-locking connection with screw retention ensures reliability during the welding process. The unit is targeted for medium-size parts such as auto taillights, expansion tanks, and intake manifolds with a welding surface of 500 cm2.

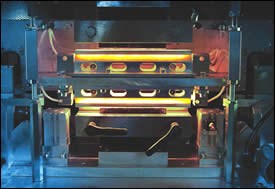

Branson also introduced the IR 40-60 Servo, a compact infrared welding machine with multiaxial servo drives specially designed for joining medium-size parts (600 × 400 mm) such as automotive glove boxes and fluid containers. Compared with standard pneumatic drives, servo drives on all three axes yield faster and more precise movements (to 500 mm/sec) and thus faster cycles.

An important feature is a wideband medium-wavelength metal-foil emitter for constant noncontact heating of the material. Embedded in a contour-aligned ceramic, the metal foil is exactly adapted to the run of the weld seam. This provides close proximity to the material and well-directed, loss-free heating. The IR welder allows clean, particle-free welding of low-viscosity materials that are unsuitable for hot-plate welding.

Dukane Corp. unveiled a new dual-servo spin welder for circular parts that require a tight tolerance for both the orientation between the welded parts and the final welded assembly height. The new design replaces the usual pneumatic Z-axis drive with a second servo motor. The control system holds orientation tolerances of ±0.1° of rotation and Z-axis tolerances of 10 microns. It also coordinates both servo motors and establishes a so-called “constant-torque” mode that enables users to specify a torque value that matches the material’s melt flow. The unitized packaging of the thruster portion of the press eliminates external cables.

HYBRID WELDERS

Several suppliers rolled out hybrid multi-process welding systems that promise greaters flexibility and performance. Some hybrids use infrared preheating for other welding techniques. Thus Branson’s M-624HRSi linear vibration welder qualifies as a hybrid, because it has a tool-integrated medium-wavelength metal-foil IR emitter.

Bielomatik of Germany introduced the K 3217, which can perform pure vibration welding, vibration welding with IR preheating, or pure IR welding. The preheating movement is controlled by two servo-driven axles. The hybrid system is claimed to offer shorter cycles and is particularly suited for car engine-compartment parts and optical components that require clean welds with low particulates.

LPKF Laser & Electronics developed a hybrid system that combines laser and halogen light for a faster welding than with lasers alone. More homogeneous heating is said to be achieved and the process window is wider. The system is designed for acrylic lenses that are welded to PC/ABS taillight housings, which are prone to stress cracks.

The new Soniqtwist welding process from Switzerland’s Telsonic Ultrasonics combines elements of vibration, spin, and ultrasonic welding. The sonotrode (horn) provides a twisting vibration at 20 kHz, with an amplitude of approximately 40 microns. The high frequency permits high energy output (12 kw) and cycle times less than 1 sec. As in conventional ultrasonic welding, the sonotrode contacts the upper part to be welded and the welding pressure produces molecular friction between the two joints, which melts the plastic.

For sensitive electronic and medical applications, this method is said to be “gentler” than standard vibration or ultrasonic welding, since there is a much smaller amplitude vibration in the parts to be joined. As compared with standard ultrasonics, Soniqtwist reportedly offers far-zone welds in the centimeter range and no “membrane effect” with films and thin components.

GAS-FUELED WELDING

Germany’s Bielomatik claims an industry first for its gas-fueled hot-plate welder. The noncontact convection system channels hot combustion gas onto the weld seam. Temperature inside the welding chamber reaches 950 C. The horizontal two-stage welding process also features servo-driven presses and integrated sensors that determine weld-seam stability directly after joining. Key benefits include quicker start-up, easy on/off capability, reduced cycle time, and lower cost than IR welding. The patent-pending equipment is not yet commercially available.

CLEANROOM ULTRASONICS

Ultrasonic welding moved to a higher level for cleanroom applications with the introduction of the Medialog welder from Germany’s Herrmann Ultrasonics. It is reportedly the first unit to comply with the FDA’s CFR.21.11 regulations for login and traceability. The machine has stainless-steel panels and a smooth finish to meet low-particle requirements. Incoming air reportedly is filtered to a high standard. Models are available with power up to 5000 W and frequencies from 20 to 35 kHz.

Switzerland’s Rinco Ultrasonics AG came out with the Standard 50 ultrasonic welder for small applications like medical components and electronic sensors. The 70-kHz benchtop unit reportedly sets new standards for precision controls and features a special low-speed cylinder that provides smooth, jerk-free operation and no force build-up in microcomponent applications. Its modular design facilitates integration into special-purpose machines.

Rinco also introduced a new ultrasonic Special Purpose Converter (SPC) and Special Purpose Actuator (SPA). The SPC is for automated welding operations with short cycles. The 35-kHz converter is spring mounted and can be used in complex applications as a substitute for compound horns. The modular, compact 20-kHz SPA has a max. stroke of 100 mm and reaches a force of up to 450 lb with compressed air at 87 psi.

Related Content

SPE Thermoforming Division Announces Biennial Parts Competition Call for Entries

This year’s parts competition includes two new categories with a focus in innovations in the use of sustainable thermoforming and in applications for electric vehicles and batteries.

Read MoreNext-Generation Workhorse Ultrasonic Welding Machines

NPE 2024: Rinco Ultrasonics’ line of standard ultrasonic welding machines significantly upgraded.

Read MoreLED Signal Tower Available in White, Cleanroom Ready

Werma’s eSIGN LED signal tower is now available in white, with a variety of signaling modes.

Read MoreOxygen Permeation System Also Tests Relative Humidity

Ametek Mocon expands Ox-Tran 2/28 instrument portfolio

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More