News in Molding Simulation at K 2013 Show

Close Up: Simulation

At October's K 2013, suppliers of injection molding simulation software displayed solutions addressing a number of hot topics, as well as technology to speed up handling of larger models and multiple iterations.

Suppliers of injection molding simulation software are addressing a number of hot topics of current interest to injection molders—conformal cooling, variotherm molding, multi-shot molding, high-strength composites, LSR, and powder molding—as well as the need for greater solving speed to enable handling of larger models and multiple iterations within a practical time frame. Those trends were evident in the new developments in simulation displayed at October’s K 2013 show in Dusseldorf, Germany.

SOPHISTICATED COOLING TECHNOLOGY

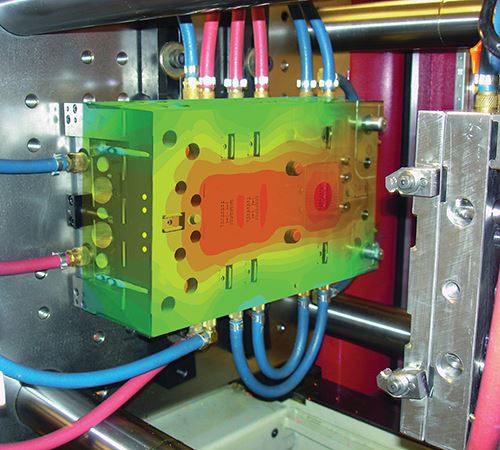

Among the latest developments from Autodesk Moldflow, Waltham, Mass., is simulation of two promising tooling technologies: conformal cooling—using Autodesk’s computational fluid dynamics (CFD) capabilities—and variotherm (hot/cold) mold cycling. For simulating the latter, Moldflow software now allows the user to change the inlet temperature cycle, which cycle can be defined by the user or controlled through a “virtual thermocouple.” Conformal cooling can be combined with variotherm technology for optimal control of mold temperature.

Also new in Autodesk Moldflow is simulation of injection-compression or pure compression molding of thermoplastics or thermosets (SMC or BMC). Also, Autodesk Moldflow is said to be investing considerable time in developing simulation for injection overmolding of continuous-fiber composite sheets. The company continues to work on simulation of liquid silicone rubber (LSR) molding, which includes building a database of material properties.

Another development project within Moldflow group is predicting surface roughness of parts made by additive manufacturing processes. Software is being developed for CAD model cleanup, simulation of the the 3D printing process, and solid modeling of the part and its visual appearance.

MEETING THE NEED FOR SPEED

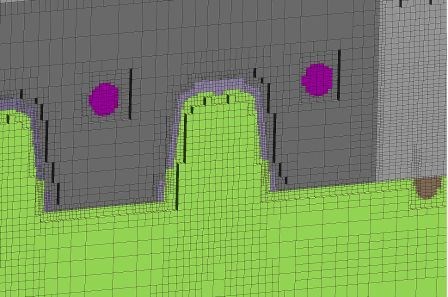

Faster optimization of new mold designs and process setups is promised by “Virtual Molding” technology introduced last fall by Sigma Engineering of Germany (U.S. office in Schaumburg, Ill.). This is made possible by the much greater speed of the latest release V5.0 of Sigmasoft simulation software. Such speed results from the ability to utilize multiple CPU cores and from redesign of the solvers so as to automatically coarsen the model mesh where fine detail is not required and refine the mesh where detail is needed, resulting in fewer mesh elements overall. The end result is the ability to simulate so much more detail of the mold than was practical before and provide multiple iterations within a reasonable time. Virtual Molding is a comprehensive 3D approach to the complete mold—including hot runners, inserts, and various mold component materials. Multiple iterations are useful for testing the effects of changing process variables on cycle time and part quality (warpage). Modeling multiple cycles also determines how long it takes a mold after startup to achieve thermal equilibrium and process stability.

For example, Sigma sources say it would have been very time-consuming in the past to model the performance of an entire hot-runner manifold over multiple cycles to take into account the long-term effects of shear heating and pressure drops. Other types of mold detail that can now be considered efficiently include small air gaps that act as heat insulators or complete hot-runner nozzles with electrical heating elements.

Sigma recently modeled a large auto instrument-panel mold that would have required an astounding 500 million mesh elements in the past, but the software automatically reduced that to 50 million elements without loss of accuracy. That’s still a very large model by historical standards, yet Sigmasoft V5.0 was able to model 40 consecutive cycles of that mold, taking just 2.5 min for each cycle. That makes it practical to test out the effect of different process settings or cooling-line layouts in Virtual Molding rather than on a real molding machine, Sigma sources explain.

The latest V.12 of Moldex3D from CoreTech System Co., Ltd. of Taiwan (U.S. office in Northville, Mich.) is up to 80% faster and can model compression molding of long- and short-fiber reinforcement orientation and its effect on thermomechanical properties through integration with Ansys Workbench for finite-element analysis (FEA). It can also predict the degree of fiber breakage in injection molding. Also new is 3D cooling CFD, which simulates water flow in 3D cooling channels to help optimize cooling design and cycle time and predict hot spots. New venting analysis can predict burn marks.

Modeling of metal or ceramic powder injection molding (PIM) and of two-component injection are other new capabilities. Others are modeling post-mold annealing and non-round runners and gates and automatic gate location in non-shell models.

Related Content

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

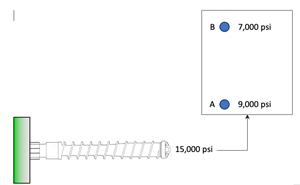

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More