NPE 2006 News Wrap-Up: Compounding

Much of the compounding news at the NPE Show in Chicago in June ad-dressed the growing trend among extrusion processors to become compounders.

Much of the compounding news at the NPE Show in Chicago in June ad-dressed the growing trend among extrusion processors to become compounders. It’s all about saving resin cost, as makers of film, sheet, profiles, and pipe put more and more mineral fillers into formulations.

But raising filler content is new to many processors, as is the extra wear it puts on their screws and barrels. At NPE, lots of methods of metal hardening were offered—some new, some not so new—but all showing more attention to abrasive and corrosive fillers.

Loading up the film

PE film processors typically add 10% to 15% calcium carbonate to formulations, though there are exceptions like recycled film for garbage bags, which may have mineral content as high as 65%. Now processors of films at all filler levels are looking to load up with more calcium carbonate. “If they’re at 10%, they’re looking at 20-25%. If they’re already at 30%, they’re looking at 40,” notes a source at one filler supplier.

At up to 10% loading, CaCO3 hurts impact properties, but from 10% to 25%, dart impact properties can double, though tensile strength drops. Above 25% loading, impact strength levels off, but with higher toughness, film can be downgauged. Adding CaCO3 also tends to makes gauge more uniform.

“The problem is that people are trying to increase filler levels with their existing single-screw extruders, which won’t properly disperse higher filler levels,” says Farrel Corp. president Alberto Shaio. If volumes are large enough, one solution is to compound higher filler levels in-house. Farrel recently sold twin-screw mixers to two plastic film processors, allowing them to go from 65% CaCO3 up to 75% in LLDPE/LDPE masterbatch. Farrel says the resin saving from that 10% increase in filler will be $1 million/yr, recovering the cost of the machine in a year. That assumes 90¢/lb for PE, 12¢/lb for 7-micron CaCO3, and processing at 2500 lb/hr.

Erema’s model TVE film-scrap repelletizer system is being used in Europe to add 20% to 55% CaCO3 to reclaimed film. Fillers are added where the cutter/compactor precuts, prewarms, and mixes material before it enters the extruder. The result is said to be less expensive pelletized material for film with higher properties.

Harder metal jackets

Two suppliers brought out new twin-screw barrel coatings to address the need for greater wear resistance coupled with better corrosion resistance. Both coatings are applied with hot isostatic pressure (HIP) powder-metallurgy. Century Extrusion announced a new HIP coating of 65% tungsten carbide in a nickel-boron matrix. Coperion Corp. introduced its new ProtectExtreme HIP coating, a powdered nickel alloy (NiCrBSi) combined with spherical borides and carbides. It’s applied in a layer 3 mm thick on the barrel and 4 mm thick at the apex between barrels.

Meanwhile, Conforma Clad has begun direct sales of its original brazed trimetallic barrel cladding, 16 years after developing it with Coperion. Conforma Clad’s WC200 (which corresponds to Coperion’s WPR 29) trimetal cladding coats a barrel with 68% tungsten carbide and forms the apexes between barrels with 62% tungsten carbide.

New compounding concept

Coperion has agreed to commercialize one of the most intriguing processing technologies of the past 25 years. It uses a combination of vibration and extensional flow to disentangle temporarily plastics’ molecular chains, producing pellets with lower viscosity that reportedly can be processed into products like thin film or thin-wall moldings using lower temperature and pressure. The effect is temporary and is accomplished without additives, change in molecular-weight distribution, or any performance tradeoff, says Coperion. The remelted plastic resumes its previous entanglements in the end product. The technology reportedly also allows for blending more thermally sensitive additives and improves the performance of recycled plastics.

This patented technology, called Tek-Flow, was developed on a lab scale by Stratek Plastics in Wallingford, Conn. Coperion will develop and market commercial-scale Tek-Flow equipment. A prototype PMC (polymer melt conditioner) machine should be in operation at Coperion in the fourth quarter to produce up to 125 lb/hr of material for test sampling. The first commercial-size PMC unit for up to 1000 lb/hr is expected next year.

Better mixing

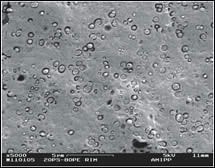

With growing popularity of more highly filled formulations, single-screw extruders have to be able to mix more like a twin-screw. Tests of a 0.625-in. Randcastle single-screw lab extruder with three Recirculator mixing sections at Rutgers University’s Polymer Science lab blended 20% PS into PE and produced mostly sub-micron PS domains without use of compatibilizers. Typically such an immiscible blend would create large (10-micron) PS domains.

Glycon Corp. showed a new turbulent mixer for aggressive mixing of non-shear-sensitive materials like PP. The patent-pending Hurricane mixer has flights that change from deep to shallow, compressing material into a deep, cross-cut reverse channel, which sends some material backward until it hits a deep forward cross-cut, which takes it to the die. The Hurricane mixing screw is being used in extrusion, injection molding, and structural foam.

Xaloy’s patented Fusion II barrier screw (U.S. Patent No. 7014353 was issued just before the show) also uses notches across flights—either across the barrier or main flight. The notches line up along the length of the screw and can be any width or depth from full root-channel depth to just a scratch. As compared with the Fusion I, this version can impart more chaotic mixing and backflow, depending on the depth of the notches.

Higher throughputs

For its Banbury batch mixers, Farrel introduced replacement mixing chambers (normally changed every three to four years) that reportedly increase output capacity by 10% to 15% while using the same gearbox, motor, and rotor center distance. The new F440 (440-liter) mixing chamber fits an existing F370 mixer. The new F305 fits an existing F270.

Maris America Corp. showed two new series of corotating twin-screw extruders for the first time in the U.S. Both have higher free volumes and throughput capacities. The HS series has a D/d ratio of 1.65 vs. 1.55 for a normal twin-screw. Maximum screw speed is 1300 rpm. Its new TM-VM series has D/d ratio of 1.78 and maximum speed of 1800 rpm. It’s de signed to incorporate large quantities of low-bulk-density fillers like talc or wood flour.

Buss Inc. USA introduced a new 67-mm size of Quantec kneader with 2200 lb/hr throughput of PVC vs. 700 lb/hr for the older generation 70-mm kneader. The Quantec uses a four-flight oscillating shaft that reportedly gives three times higher throughput than a traditional three-flight Buss kneader. Mixed material is discharged into a short, 4:1 L/D hot-melt extruder and hot-face pelletizer.

Italian twin-screw maker ICMA San Giorgio has a new calendering system for thin insulating sheet (1 to 8 mm thick) made from 15% powdered copper, 65% CaCO3, and 20% EVA. The sheet is applied to PS foam panels for electromagnetic shielding and heat and sound insulation. It requires a large, 500-mm-diam., three-roll calender to make 1.5-meter-wide rolls. But the sheet is so heavy that it can be rolled into only very small rolls (250 mm diam.) that weigh 55 lb apiece.

Achieving better bimodal polyolefin compounds is the object of Coperion’s ZSK-NT (new tandem) twin-screw, which pairs a short (20:1), high-speed (350 to 700 rpm) twin-screw for melting the resin with a long (24:1), slow (80 to 150 rpm) twin extruder for mixing. Coperion has sold the first two systems for PE pipe.

Related Content

BASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreCompatibilizer for Nylon/ABS Alloys

CAI Performance Additives’ ST-AN3230 has shown to improve both compatibility and performance of nylon/ABS alloys.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MoreTosaf’s Investments in North America Result in 40% Increase in Production Capacity

Backed by a global presence, Tosaf provides localized additive and color solutions, and services for the plastic industry in North America.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More