NPE Trend Watch: Predictive Maintenance

New technology allows processors to address equipment and component hiccups before they start to foul up manufacturing.

If an ounce of prevention is worth a pound of cure, how much is a pound of “prediction” worth? According to firms developing new technology aimed at keeping manufacturing equipment up and running, the answer is: a lot of money.

Many plastics processors—particularly those in North America—are known to have adopted an equipment-maintenance policy (either on purpose or by practice) called “run to fail.” That basically means you operate your equipment until you can’t anymore. In “run to fail,” according to the maintenance and asset-management website fiixsoftware.com, “assets are deliberately allowed to operate until they break down, at which point reactive maintenance is performed. No maintenance, including preventative maintenance, is performed on the asset up until the failure event. Importantly, a plan is in place ahead of the failure, so that the asset can be fixed without causing production issues.”

The website continues, “Under ‘run to fail,’ it is important to have spare parts and staff on hand to replace the failed part and to keep availability above organizational requirements. This strategy is useful for assets that, on breakdown, pose no safety risks and have minimal effect on production.”

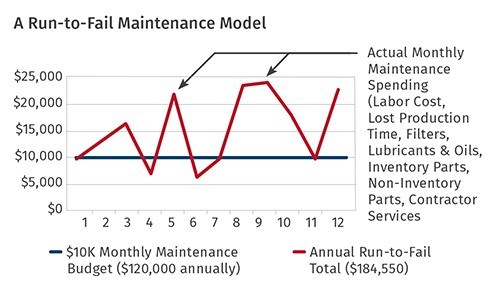

A run-to-fail strategy for, say, light bulbs, is perfectly reasonable. But why would a plastics processor, operating in a highly competitive environment, eschew basic maintenance procedures on primary and auxiliary equipment and essentially beat the heck out of the equipment until it collapses. With “run to fail” you’ll no doubt be paying more over the long haul than in the short term (see chart).

When plant maintenance and production cross swords, who wins that battle?

To be fair, many processors have implemented preventive (or scheduled) maintenance programs aimed at getting machinery and components repaired before bad stuff happens. But what happens if an injection molding machine is due for a preventive-maintenance check when it is in the middle of a huge production run? When plant maintenance and production cross swords, who wins that battle? What happens during production when an alarm sounds? Odds are, unless it’s signaling a dangerous condition, as opposed to a more minor “malfunction,” it’s silenced.

That brings us to what will undoubtedly be a significant trend at NPE2018: Sensor and software technology that allows processors to detect machinery and component problems before they wreak havoc on production. It’s called predictive maintenance. As Plastics Technology Executive Editor Matt Naitove explained it in a blog, “Predictive maintenance is an essential strategy for obtaining maximum machine efficiency and uptime. The idea is to install sensors on processing machines that will measure vibrations, torques, temperatures, pressures, electrical functions, and other things like oil quality (particle count), level, and moisture content.”

When you think about it a bit, the idea of mounting sensors on industrial machinery to monitor their condition is essentially an extension of technology that consumers have been using for years by wearing watches and other devices that monitor their temperature, heart rate, and so forth. “What we’re doing is helping bring this technology into an industrial environment where ‘run to fail’ is too often the norm,” remarks Conrad Bessemer, president and CEO of Novatec Inc., Baltimore, a licensee of predictive-maintenance technology firm MachineSense/Prophecy Sensorlytics.

Mounting sensors on machines and sending a signal that something’s awry is one thing. But the key is software algorithms that provide “actionable advice” on what to do about it.

MachineSense/Prophecy Sensorlytics introduced this technology in a big way at NPE2015. Since then, injection machine builders such as Engel (U.S. office in York, Pennsylvania) and Wittmann-Battenfeld (Torrington, Connecticut) have introduced predictive-maintenance platforms of their own. Interestingly, Naitove recalls that more than a decade ago, Coperion Corp., Sewell, New Jersey (then called Werner & Pfleiderer), promoted the idea of putting vibration sensors on compounding equipment to sense the health of drive bearings. And at K 2013, Leistritz (Somerville, New Jersey) displayed a twin-screw compounding extruder with an “intelligent screw” system appropriately dubbed Smart Screw. The screw’s smarts are obtained via an embedded RFID chip, which keeps track of, and can log and store, machine data such as operating time, formulations, and specific processing values.

The real key is what to do with this data. Mounting sensors on machines and sending a signal that something’s awry is one thing. But the key is software algorithms that provide “actionable advice” on what to do about it. That becomes especially critical at a time when processors have fewer and fewer maintenance technicians on-site. States Bessemer, “There is a big difference between condition monitoring and predictive maintenance. Pumps, for example, are typically furnished with only a local vacuum gauge. Controls can track motor faults and vacuum with costly sensors, etc., and alarm when something is wrong. That’s condition monitoring. But even condition monitoring has typically never been available for conveying pumps.

“Lots of times, when the alarm sounds, the production people turn it off,” Bessemer continues. “With predictive-maintenance technology, on the other hand, analytics are used to establish an operating baseline, and the software predicts what is going to happen ... as opposed to reporting what did happen.”

Another key to how quickly processors embrace what to many will be an entirely new concept is retrofitability. U.S. plastics processors are highly unlikely to replace functioning equipment with brand-new machines just because they can predict when a component will fail. But having the ability to mount sensors and capture data on existing machinery might be a different proposition altogether.

And now the technology is being advanced to help processors solve power problems. Low-quality power is said to cost plastics processors $9.6 billion a year. According to the Electric Power Research Institute (EPRI), poor power quality is costing the U.S. economy up to $188 billion a year. What’s more, the EPRI estimates that 80 percent of power-quality problems are generated from issues within a facility. MachineSense/Prophecy Sensorlytics is one company that has developed a solution.

Predictive maintenance is more than a buzzword; expect to see it highlighted at a number of booths. Among those entering the arena will be Conair, Cranberry Township, Pa. At NPE2018, it will launch a new program called Smart Services to assist customers in monitoring equipment, anticipating problems and responding proactively. Explains Sam Rajkovich, Conair’s v.p. sales and marketing, “As we see it, the key lies in data analytics. Auxiliary equipment generates a tremendous amount of useful data on its own… even without the need for special sensors. We just need to process that data in a way that is timely and informative. That’s what we think is the real secret to predictive maintenance.”

Some may be of the mindset that predictive and prescriptive maintenance technology, as well as so-called “smart machines,” will wind up “unemploying” people. Fact is, though, the technology is all about making existing personnel more productive and smarter—because finding enough skilled technicians and other labor is a problem in manufacturing not likely to be solved soon.

Time to bid farewell to run to fail.

Related Content

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreNPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More