On-Site: An ‘Empire’ Built on Scientific Molding

A U.S. custom injection molder that’s hiring?

A U.S. custom injection molder that’s hiring? You couldn’t miss the on-line “help wanted” notices this summer when visiting empireprecision.com, the website belonging to molder and moldmaker Empire Precision in Rochester, N.Y. And when visiting the company in person, you’ll quickly learn what company officials believe to be a key reason for their company’s growth: From the top to the shop, Empire Precision has fully embraced the principles of “Scientific Molding.” What’s more, the company has developed and implemented a proprietary business system for putting those principles into practice.

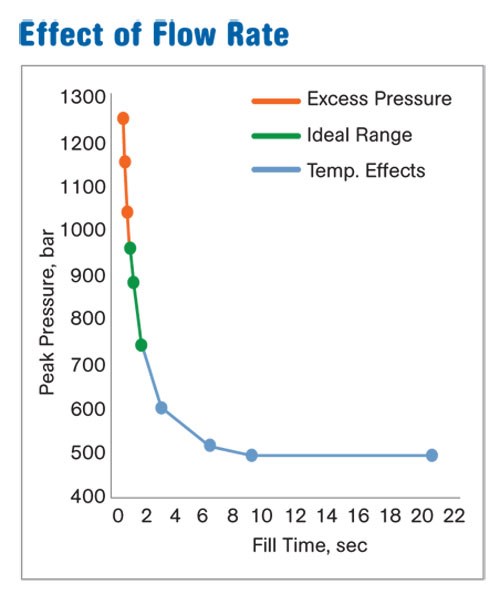

Scientific Molding, promulgated by Plastics Technology columnist, John Bozzelli—the founder of Injection Molding Solutions (a.k.a. Scientific Molding), Midland, Mich. (scientificmolding.com)—is a procedure for optimizing the molding process by managing material viscosity through the control of material temperature and pressure, injection velocity, and mold temperature. Neal P. Elli, president of Empire Precision, says his company’s adoption and adaptation of these principles began about eight years ago after attending a Scientific Molding seminar.

“We decided that what we really needed was to create a process,” he explains. “We didn’t create a new way to process plastics. We built a business system. We take all of the important data when we develop a process, fine-tune it, and we put it into a software package that we wrote and store in a captive online database. It’s a procedure that’s been in place now for more than five years.

“Once we establish the process that we’re going to use in production, it’s a frozen process, and that’s what we run. We don’t ‘process at will’ anymore. Everything drives back to the pedigree of that very specific process.”

Elli believes there’s much more involved in Scientific Molding than simply using process-monitoring sensors: “I think that Scientific Molding has nothing to do with sensors. But if you develop a process along its principles, and then you put sensors on it, you can assess how you’re doing. It kind of ‘opens up’ the mold and lets you see what’s going on inside before waiting for it to actually open up and knock out a part.

“In my mind, it’s all about how you build a mold, and how you build a process that allows the molding machine to control material viscosity, so you’ll fill the tool consistently shot after shot.”

COURAGE CATALYST

Empire needs a “scientific” approach for its kind of molding. At its 42,500-ft², facility, it specializes in precision, intricately detailed, small and micro parts—some weighing less than 0.1 g—for medical, electrical/electronic, industrial, and consumer products. The firm is also proficient in MuCell microcellular molding (trexel.com) and multicomponent, two-shot parts. Empire is ISO 9001 and 13485 registered, UL46D recognized, and TS 16949 compliant.

Empire runs parts in filled and unfilled engineering resins—everything from acetal, PPO alloy, and TPE to PPA, PEI, PPS, PEEK, and LCP. Mold temperatures of 500 to 800 F are routine. Empire uses a little less that 40,000 lb/month of materials to manufacture and ship 7 million to 10 million parts a year. Average annual sales are approximately $8 million.

“Scientific Molding takes the fear out of molding engineering materials,” states Mark Trudeau, a Six Sigma Master Black Belt, and the company’s director of operations. “Without theory, you run completely on experience, which is fine, but I don’t believe it allows you to control technology.”

Empire Precision has an active Six Sigma program in place. In addition to Trudeau’s black belt, Gary Oliver, senior process engineer; Steve Steinmetz, production manager; and Chris Judd, quality director are Green Belts.

Operating three shifts, 24/7, the company employs 55 and runs 40 molding machines, mostly from Arburg and Sumitomo. It operates an ISO Class 7 clean room, and its secondary operations include light assembly, pad printing, machining, ultrasonic welding, and part functionality testing.

ERP software from IQMS, run through a wireless router, monitors every machine to help manage production. Process monitoring is accomplished through a data-acquisition system supplied by RJG Inc. (rjginc.com).

PREDICTIVE PROCEDURES

Empire also designs and manufactures molds. Employing eight toolmakers, it provides everything from prototype mold manufacturing and engineering changes to complete builds—both for its own use and for captive molding customers.

What it can’t build in-house it outsources from established local moldmakers and specialized regional and offshore partners. Additionally, Empire builds hot-runner tooling, incorporating systems primarily from PolyShot, Mold-Masters, and Heitec. It can make mold bases and pins, but it mostly focuses on core and cavity work.

Its highly automated moldmaking capabilities include wire and sinker CNC EDM, high-speed CNC milling, grinding, and polishing. An eye-catcher is its Makino E33, a late-model high-speed mill. It’s serviced by a 3R Robotic system. A late-model EDM sinker nearby runs unattended.

Empire uses Autodesk’s Moldflow software (moldflow.com), of which Toolroom Manager Scott McLaren says, “It won’t tell us everything, but it helps us run molds in our equipment using Scientific Molding. It helps us to optimize tool design and predict potential problems and risks during the design phase.”

Adds McLaren: “Our designs may take a little bit longer, since we use Scientific Molding principles for process prediction and Moldflow to assess mold designs, but these procedures help us get the process ‘scripted’ before we start to build the tool. An easier way to manufacture a mold might make it harder to mold a good part.”

PEDIGREED PRODUCTION

Empire Precision has about 450 active molds and makes three to five mold changes per shift. Most of its tools are built in S-70 or H-13 steel, though it usually uses stainless steel for medical projects. Empire has also built aluminum tools from day one, which are now growing in popularity among injection molders because of their superior heat transfer and faster machining. Empire has run a million cycles off on one of its aluminum molds. On occasion it also has built aluminum/steel “hybrid” tooling.

Elli notes that the company has found Scientific Molding to be an important tool for analyzing and remedying problems with incoming molds. “We’ve developed a process for diagnosing tools that allows us to talk to our customers in a factual way about what’s going on with transfer tooling. That’s one reason why we’re a vendor of choice for transfers. We can get that tool up, running, and making the best parts it’s capable of producing as fast, or faster, than anyone else, while also backing it up with ‘process-pedigree’ documentation to produce consistent parts going forward.”

EVIDENT EXCELLENCE

On Empire’s manufacturing floor, under 23-ft-high ceilings, materials are pneumatically conveyed above the center spacing between three rows of machines, which prevents any possibility of materials and molded parts competing for floorspace. The shop floor is currently lit by sodium halite lighting, but Empire will convert to energy-efficient compact fluorescent lighting later this year.

Virtually all of the company’s manufacturing auxiliaries—from suppliers such as Novatec, Advantage Engineering, and Rapid Granulator—are backed-up with spares. Both power systems and heat exchangers are used with redundant pumps. Elli says the in-house team that laid out the shop floor made sure to reserve space for a preventive-maintenance staging area and for equipment cleaning.

“I must have one of the smallest screw/barrel sizes in the business on all my presses,” he adds. “For instance, on an 80-tonner, I’ll usually have an 3-oz barrel. We use the smallest shot size that we can get in order to apply more melt pressure and to ensure that we’re not pressure-limited.”

One other thing you’ll notice on the shop floor is a digital display screen at every molding station. Each press can be monitored by Empire’s proprietary “Fill Analysis Software,” which presents a visual, shot-to-shot verification that key process parameters are run in compliance with setpoints generated by the company’s Scientific Molding design of experiments (DOE).

“That’s a tangible event that we can go back to when we develop a process. It also helps us when, for whatever reason, customers change materials. And it shows us how to evaluate tools that come in, regardless of who built them and where they came from.”

With a capital investment of approximately $4 million, Elli expects Empire’s current sales volume of $8 million to rocket to $20 million in less than four years through the use of procedures the company has developed under the influence of Scientific Molding.

As for hiring… at last count, Empire Precision has added a project manager, a tooling engineer/quoter, a scheduler, maintenance personnel, machine operators, and materials specialists since posting its online help-wanted ad.

Related Content

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More