Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.

“Let’s just build it ourselves,” is the motto of Axiom Group Inc. and, more specifically, of its president, Perry Rizzo. An airplane pilot by training, and an “engineer by passion,” Rizzo is constitutionally averse to compromising on quality or efficiency. That’s why he didn’t hesitate to design and build a child’s lunchbox when he couldn’t find one on the market that would keep both soup hot and a sandwich cold. He used that same approach when it came to production-monitoring and ERP systems for Axiom, a Canadian Tier 1 automotive molder and moldmaker, of which he is co-founder and co-owner.

Based in Aurora, Ont., and with a plant in Mexico and a partner plant in Italy, Axiom is a $50-million-plus (U.S.D.) business that employs 250. Its headquarters plant occupies 80,000 ft2 and houses 31 injection machines from 200 to 1500 tons, including six two-shot machines and a pair of rotary-table vertical presses. A second plant in Aurora houses its tooling department, called Intex Tooling Technologies, which builds all Axiom’s molds, and its software development activities for production monitoring and ERP.

Software development—Axiom’s most recent venture—is the key to Rizzo’s focus on “driving out waste in the system” and becoming “the Industry 4.0 ‘smart factory’ of Canada.”

‘HOMEBREW’ SOLUTIONS

Three to four years ago, Axiom started looking around for a production-monitoring system and concluded that the commercial products on the market were too costly and too complex, requiring weeks of personnel training and expensive installation. “Let’s build our own,” was Rizzo’s response.

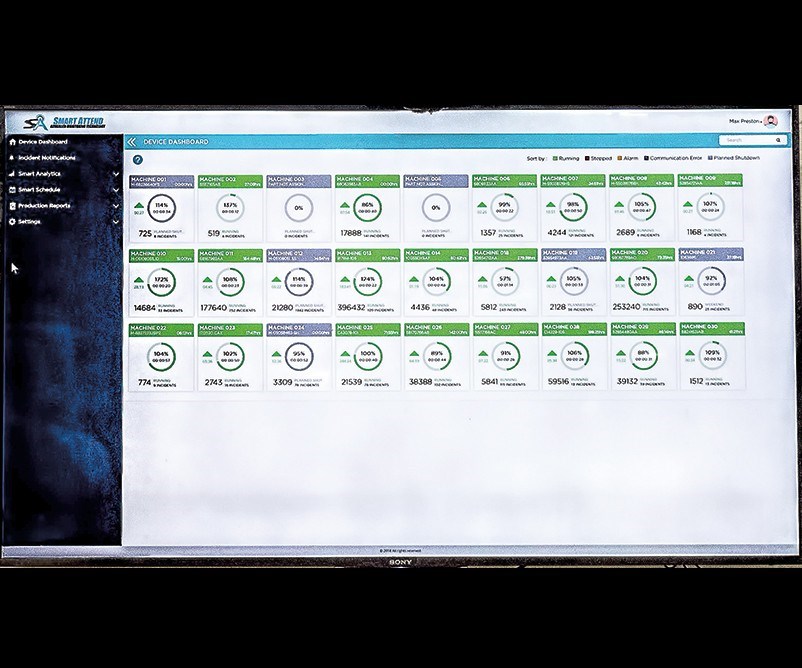

The result was Smart Attend, the first prototype of which was installed on an injection machine in late 2016. It is now used on all injection machines at Aurora, and on machining systems in its tooling operations. Smart-Attend terminals are at each lead hand’s desk and in the central office. A large Smart Attend screen is located on a wall of the molding floor and has become an anchor site for production team meetings. Last June, Smart Attend became available commercially to other processors and moldmakers.

As explained by Max Preston, director of sales and marketing for Smart Attend, “We decided that the ‘smart factory’ should not be only for large multinational organizations. We built Smart Attend to bring the benefits of real-time manufacturing data to entry-level companies and owner-operated firms that need to move themselves forward in competitiveness.”

As explained in detail in a January Keeping Up, Smart Attend collects data (such as 24V I/O signals) from injection machines, extruders, CNC machines, or other equipment and connects to the plant’s WiFi network to send data to PCs via web browser or to mobile devices via the Smart Attend app for iOS or Android. Data is collected by a small, WiFi-enabled box that sends encrypted data to a secure “cloud” server. A backup 2GB memory card ensures that data is never lost and can be collected in case of a network disconnect. Any brand of machine of any age can be connected to the system.

Preston says initial configuration can be completed in as little as 20 min without requiring IT or special training. Overall installation time averages 2-4 hr. Smart Attend makes data available in three ways. First, a tower light (also made by Axiom) displays machine status and alarms in customizeable colors and modes—flash, strobe, or solid color. Second, a powerful speaker atop the tower light accepts custom sound files to represent specific alarms. And third, the data collected by the system is available on a user “dashboard” that provides a quick overview of plantwide data and the ability to home in any individual machine. The dashboard provides cycle times, machine status, part counts, alarm description, Pareto analysis of downtime causes, hourly incident reporting, job scheduling and tracking, and machine OEE (Overall Equipment Effectiveness).

The essence of the dashboard, says Preston, is immediate availability of important, useful data—not a digital blizzard of information—to everyone who can use it. “With Smart Attend, data goes instantly from machines to managers.” Smart Attend will exhibit at NPE2018 next month in Booth S10029. (Intex Tooling Technologies will be in Booth S32053.)

The development of Axiom’s own ERP (enterprise resource planning) software, called Prism, followed a similar trajectory. Rizzo says, “We didn’t have a good experience with a commercial ERP system. It was too complex and inflexible. So we pulled the plug after a full year of attempted implementation.”

What followed were several years of full-time software development that resulted in Prism. “It tracks everything from when it comes in the front door to when it goes out the back door for shipping,” says Rizzo. “The key thing is that it works in real time. It provides lot traceability to the second. It tells us in real time, which operators are on the floor and which operator made which part.”

All Prism data are available to shop personnel on tablet computers. “We’re a paperless operation,” Preston notes. All inspection data is also available on the tablets. Quality data is available in real time throughout the plant. A digital image of a part defect can be sent to the operator’s tablet in minutes.

Axiom has integrated Smart Attend with Prism. Rizzo says that combination is so powerful that he can see doing inventory only once a year in future, instead of twice annually now. What’s more, he says that having comprehensive production data means “we can allow lead hands to create, start, pause, and end jobs on the shop floor to keep machines occupied. Equipment utilization is not all driven from the head office.” Wide availability of data, Rizzo states, makes possible “real-time manufacturing,” whose key elements are “accountability, ownership, empowerment.”

Axiom plans to market Prism in the long term, and is willing to discuss it with visitors to its NPE booth. Next steps for the system will include adding interactive video streaming on topics such as how to inspect a particular part for quality issues.

WHAT’S IT ALL WORTH?

With Smart Attend, Axiom gained four to five percentage points of OEE, according to Rizzo. “That’s worth tens of thousands of dollars a month to us.” OEE is a metric used widely in the automotive and other industries. It combines equipment availability (uptime), productivity performance (cycle time), and good/bad parts production (quality) into a single percentage number. Rizzo says OEE of 70-80% is average for the plastics industry; greater than 80% is “very good.” Axiom has achieved 89-91% since implementing Smart Attend.

Rizzo adds, “Our five-year global quality rating from the auto industry is 100%, delivery rating is 100%, warranty rating is 100%, and overall system cost rating is 98%.”

This gets to what Rizzo defines as the most immediately relevant meaning of Industry 4.0. The term has been applied widely by machinery producers to data communication from machine to machine. That will no doubt have value, Rizzo agrees; but for him, there is much greater immediate benefit for company managers from having crucial manufacturing data in real time to enable prompt and accurate decision making. “We transformed into an Industry 4.0 facility without buying a single new piece of machinery.”

He cites the example of Smart Attend’s Pareto charts that make it quickly apparent to managers where (or when) their biggest—and most expensive—sources of downtime and quality problems are occurring. “It takes away redundant, burdensome thought processes from managers and highlights their top three or five issues that need attention.” The future of Smart Attend, Rizzo hints, may be application of artificial intelligence to identify trends that are costing the plant money. “For us, the importance of Smart Attend has been monumental,” says Rizzo. “We’re a lean Just-in-Time operation. We don’t hold safety stock for our customers. We can’t make mistakes.” Before Smart Attend, he notes, Axiom sometimes made more parts than necessary—which wastes money and resources. “In the automotive business, do you know what it costs to miss an order ship date? Or to short-ship an order? Or the cost to expedite a shipment that would be late because of production problems?” In fact, Axiom saved thousands of dollars in the first week of using Smart Attend by not having to expedite parts shipments, thanks to better production data.

“Our biggest problem in implementing Prism was the human interaction—manually entered data, which could be missing or inaccurate. Smart Attend ends that. Smart Attend does not have opinions; it has data. It tells us that we made so many parts by counting cycles. Prism tells us that so many boxes of parts were barcode scanned into the system. If there’s a difference between the two, we know to start asking, ‘Where did the parts go?’ For example, Smart Attend told us that on one job that was making left and right-hand parts in the same mold, we were scrapping out left-hand parts. But the parts are shipped in pairs—so what happened to the extra right-hand parts?”

Rizzo notes that “every day brings another story of what Smart Attend did.” On one night shift, Smart Attend sent an alert to a manager at his home. He contacted the lead person, who reported that parts were sticking and the robot was struggling to get the parts off the mold. The manager checked Smart Attend, and saw that cycle time on that job had stretched from the usual 45 sec to 70 sec. He then asked if any new operators were working that job. The lead person checked and found that, yes, new operators were being trained, and that was responsible for cycle times lengthening, leaving time for parts to shrink tighter on the mold and resist removal. Put experienced operators on that job now, the manager ordered. And sure enough, the sticking problem went away. The moral of the story, says Rizzo: “Without the data from Smart Attend to give the manager a clue to the cause, we might have pulled the mold and sent it out for polishing—which would have been a huge, unnecessary cost and delay.”

Data-driven decision making, says Rizzo, “is a quantum shift in how people run their business. In many shops today, people come in Monday morning—or any morning—and get together to discuss the weekend’s or last night’s problems, and then people fan out to try to gather information on what went wrong and why. With Smart Attend, there’s no need for morning meetings. Problems were identified when the issue happened overnight; the appropriate people were notified; and they had data in their hands that could help them find a solution right away.”

Related Content

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

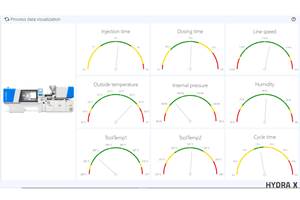

Read MoreManufacturers’ Superpower: ‘X-Ray Vision’ into Your Processes

Meet a ‘new’ name (to North American processors) in MES software, which provides a simple, modular way to achieve visibility into your production operations.

Read MoreLSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

Read MoreEquipment Suppliers Show Adaptability and Smarts at TaipeiPlas 2024

Customizable equipment solutions, warm hand-off support, and seamless software integrations highlight Taiwan’s plastics show.

Read MoreRead Next

Injection Molding: Production Monitoring System Built for Simplicity, Affordability

Smart Attend reportedly installs in 2-4 hr and boosts productivity by 10-20% within two weeks.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More