‘Passive Variotherm’ Cooling Cuts Cycle Time at Low Cost

NPE Preview

A hot/cold molding technique lets the injected melt do the heating while water flow is paused.

Energy efficiency is one of the key elements of efficient plastics processing. Solutions that reduce cycle times without consuming more energy are particularly attractive. At next month’s NPE2015 show in Orlando, Fla., Single Temperature Controls, Inc., Charlotte, N.C., will highlight an approach to variotherm mold-temperature control that does not require active heating and cooling from an alternating temperature-control system. A less complex, less costly, “passive” system reportedly can often achieve cycle time reduction while also saving a substantial amount of energy.

ACTIVE VS. PASSIVE HEATING

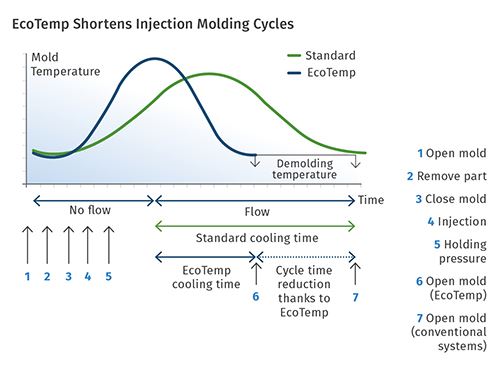

“Dynamic,” “cyclical,” or “variotherm” mold-temperature control is an increasingly widespread technology for improving the quality of injection molded parts by first heating the cavity wall above the glass-transition temperature of the plastic during melt

injection, followed by cooling to solidify the part after the cavity is filled. Such hot/cold mold cycling reportedly can improve the reproduction of gloss or fine surface detail of injection molded parts, increase dimensional stability through reduced stresses, and decrease cycle times.

Active systems such as Single’s ATT (Alternating Temperature Technology) alternately pass warm and cold fluids through the cooling circuit. Other active systems use electromagnetic induction coils in the mold for heating, together with water cooling. Both require investment in special equipment and modifications to the mold.

Passive approaches, such as Single’s EcoTemp system to be shown at NPE, interrupt water flow for mold cooling during the injection phase, so that the cavity wall heats up by conduction of thermal energy from the injected melt. This is followed by an intense cooling phase, which can use 10-20% lower water temperatures than standard constant-temperature cooling systems.

EcoTemp can be integrated into all Single water-temperature control units. In practice, it is used mostly at water temperatures of up to 90 C/194 F but can be used with up to 150 C/302 F pressurized-water systems. EcoTemp uses cycle-dependent signals from the injection molding machine to control the start and stop of cooling fluid circulation. Because this involves little or no additional investment, Dr. Babak Farrokhzad, director of sales and marketing at Single Temperiertechnich GmbH in Germany, has called it “a poor man’s variotherm.”

ADVANTAGES CONFIRMED

EcoTemp has been marketed in Europe for five years but NPE will mark its U.S. introduction. According to Dr. Farrokhzad, European experience on around 350 injection presses show these advantages:

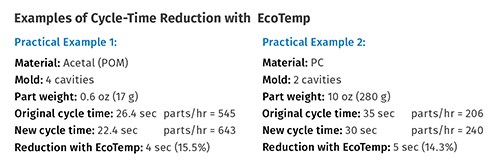

• Double-digit reduction of cycle times—by an average of 60.6% in European production. Two examples are shown in the accompanying table.

• Longer application of holding pressure, even in areas away from the gate, because melt does not freeze immediately in contact with the mold.

• Lower injection and holding pressures, potentially allowing use of a smaller injection press.

• More homogeneous glass-fiber orientation in engineering components.

• Longer fusing time for melt fronts and minimized weld lines.

• Lower risk of warpage as a result of molded-in stresses.

• No extra equipment or alterations to the mold.

Productivity advantages were also confirmed in a study by the respected Institute of Plastics Processing (IKV) at RWTH Aachen University in Aachen, Germany. On a sample mold, using PC/ABS material, conventional temperature control with a water supply temperature of 80 C was compared with with the EcoTemp system operating with a lower supply temperature and a cooling-time interruption of 14 sec. All other process parameters were kept constant. The cooling time was selected to achieve a maximum demolding temperature of 90 C in the area near the gate. Under these conditions, the quality of the molded parts would be comparable in both cases, according to the researchers.

The cycle time required by the conventional system to reach the maximum demolding temperature was 33 sec, while the EcoTemp system took 7.5 sec less, an 18.5% reduction. At the same maximum temperatures at the gate, the demolding temperature of the rest of the part surface was about 20° C lower with the EcoTemp system, as revealed by thermographic imaging of the parts after demolding. This was due to the lower mold temperature achieved by the EcoTemp system. While the cooling-time interruption with EcoTemp resulted in a mold-surface temperature 7-10° C above the water-supply temperature, it was still 30° C lower than that achieved by conventional temperature control. “The EcoTemp system shows a slightly higher temperature increase, but also faster and more efficient cooling,” said Sergio Rigano, ATT specialist at Single.

He notes that, for maximum efficiency and profitability, either EcoTemp, active variotherm, or conventional mold-cooling methods should be applied in combination with molds that provide good thermal conductivity, ensure an effective heat transfer to the cavity, and have a low mass to be cooled/heated. In order to keep this mass to a minimum, small inserts with conformal cooling/heating channels are recommended. These inserts can be designed by means of additive-manufacturing methods such as 3D printing or lasercusing, which build up these inserts layer by layer from steel powder

so that the integrated cooling channels closely follow the cavity surface contour and run very close to the cavity wall.

NEW CONTROLLER

Also to be shown at NPE is Single’s new “intelligent” controller for EcoTemp and other Single temperature-control units. It is user-configurable, easy to use, and multi-lingual, notes Frank Spork, Single’s managing director. It has a scrollable touchscreen that resembles a smartphone in design. It runs in Basic and Expert modes, and allows storage of 20 mold recipes. Special features include notification of upcoming scheduled maintenance, a list of spare parts, and service contact information. Spork says the next upgrade will be remote access via the Internet.

Related Content

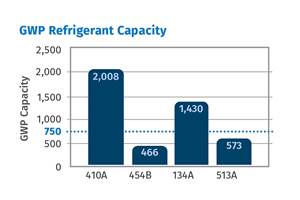

Chiller Lines Updated to EPA-Approved Refrigerants

Thermal Care’s chillers now utilize EPA-approved low Global Warming Potential (GWP) R‐454B and R‐513A refrigerants.

Read MoreTemperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreACS Group Adds Regional Sales Manager

Richard Gutierrez named Southwest regional sales manager.

Read MoreIs Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More