Prevent Streaks & Specks From Vented Extruders

With vented extrusion, small amounts of melt can hang up on the screw and degrade, eventually resulting in streaks or specks that hurt the appearance of the extruded product.

With vented extrusion, small amounts of melt can hang up on the screw and degrade, eventually resulting in streaks or specks that hurt the appearance of the extruded product. This problem can be tricky to diagnose, however, because it may only appear hours or even days after the material actually degraded.

Vents have long been used in single- and twin-screw extrusion for hygroscopic or powdered resins to remove moisture and entrapped air. Now vents are increasingly used for direct extrusion of a range of other materials, including highly filled polyolefins, in which powdered mineral fillers trap air; recycled resins, from which moisture and volatiles must be removed; and wood-filled composites, which are highly sensitive to moisture.

A vent is an opening in the extruder barrel roughly two-thirds of the way down the barrel, which allows trapped gasses to escape from the melt. An extruder with one vent uses a screw with two stages, one on either side of the vent. Such screws are designed with more conveying capacity in the second stage than the first, creating zero pressure under the vent.

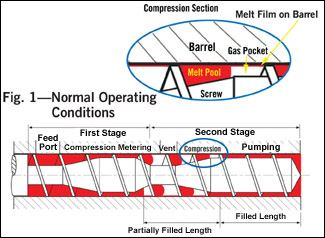

The first stage of a vented screw consists of three sections: deep-flighted feed, tapered compression, and shallow metering. This stage is where solids conveying and melting take place. The second stage also has three sections: deep-flighted extraction, tapered compression, and shallow metering. The extraction and compression sections devolatilize the melt, while the metering/pumping section develops pressure ahead of the die.

Where trouble starts

Appearance problems begin in the deep channels in the compression section of the second stage of the screw and are caused by fluctuations in melt pressure. These fluctuations in turn cause variations in the filled length of the screw.

In the second stage, the screw is partially filled in the extraction and compression sections and completely full in the last part of the pumping section. But the lengths that are partially and completely full can vary. Their lengths are determined by the amount of pressure generated in the pumping section.

If barrel pressure increases, the filled length gets longer, and the partially filled length gets correspondingly shorter. Conversely, if pressure drops, the filled length gets shorter and the partially filled length grows longer.

Degradation isn’t normally a problem in the filled length of the screw because melt that is close to the screw surface is constantly dragged away and replaced by new melt, while melt coating the barrel is constantly scraped by the screw flight.

Normally, the partially filled length has a melt pool at the pushing side of the screw flight, a melt film along the barrel, and a gas pocket between the melt pool and the trailing side of the screw flight. There is normally no melt on the unfilled surface of the screw.

As the filled length gets shorter, it leaves a film of melt behind on the now-empty surface of the screw. This melt film can’t be dragged or scraped away because there’s only a gas pocket over it. Since this film is at high temperature, it degrades in a matter of hours.

It may, however, take days before this degraded melt actually contaminates the extruded product. This only happens when the filled length increases again. As the flights fill with melt, the new melt picks up the old degraded material and carries it along.

Solving the problem

The key to solving this degradation problem is understanding the mechanism behind it: variations in barrel pressure. Every effort should be made to run the extruder with minimal variation in pressure.

It’s important that the pumping section generate good pressure. Optimum pressure depends on the melt viscosity and degree of shear thinning of the resin used. When several plastics will be run with the same screw, the screw design should be based on the resin with the lowest viscosity and highest degree of shear thinning. Large flank radii on the flights and a low-friction screw coating also help reduce hang-up of resin on the screw.

Many other factors affect barrel pressure and thus can cause a change in filled length. These include build-up of contamination on the screen pack and changes in any of the following parameters: screen-pack configuration, choker-bar setting inside the die, die gap, die or barrel temperature, and screw speed. But this is by no means an exhaustive list of possible culprits.

One solution to the contamination problem is to change screens more frequently—before the barrel pressure increases too much—with the help of an automatic screen changer, for example. A pressure increase of more than 1000 psi (about 7 MPa) is generally too much. A pressure increase between screen changes of only a few hundred psi (1-2 MPa) is more appropriate.

Using a melt pump may also help reduce pressure fluctuations, but it does not eliminate them because the screen pack is generally placed before the melt pump in order to keep contamination out of the pump.

Purging agents don’t necessarily clean up this degradation problem because they only work in the filled sections of the screw. Purging agents can’t clean a surface with which they aren’t in intimate contact, as is the case in partially filled flights.

The surest way to avoid the degradation problem is to pull and clean the screw each time the screen pack is changed. This may not be practical if you have to make frequent screen changes.

Pulling the screw is also a good way to identify the problem and see if there is degraded plastic in the compression and pumping regions. If there is degraded material present, this is likely caused by variations in the filled length. This is almost certain to cause appearance problems eventually, even if they haven’t yet become visible.

Related Content

Use Purging Compounds to Mitigate Processing Challenges of PCR and PIR

With frequent purging, you can minimize serious contamination issues and get both better results and higher profits.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreCast Acrylic Purging Compound

Mechanical purging compound comes in granulate form, enhancing handling, storage and grittiness for cleaning.

Read MoreMarket Changes Spur Industrial Recycler to Enhance Capabilities in Clear Plastic Reprocessing

Butler MacDonald found new business and flexibility thanks to a big step-up in purging efficiency.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More