Process Improvement Tools Starred at Fall Rotomolding Show

A new approach to faster cycles focuses on resin modification rather than mold or machine technology.

A new approach to faster cycles focuses on resin modification rather than mold or machine technology. This, plus advances in mold temperature and pressure monitoring and a new ovenless molding concept, were some of the highlights of the recent 31st Annual Fall Meeting of the Association of Rotational Molders in Washington, D.C.

Use resin to speed cycles

A. Schulman has developed a novel resin modification that reportedly brings the melt to an optimum cure in a shorter time than can be achieved by modifying molds or machinery. By attaining optimum cure, Schulman’s proprietary Better Parts Faster (BPF) compounding technology is said to attain the best physical properties while shortening oven cycle times up to 25% and decreasing cooling times about 10% compared with conventional methods.

BPF was developed to help molders increase throughput without additional labor or equipment. The technology can be used when a molder is running several parts of different thicknesses on a single arm. BPF assists by curing the thicker parts faster to bring them more in line with thinner sections’ cure times. Also, molders running parts with dissimilar colors can rectify throughput imbalances.

BPF technology can be compounded into any polyethylene, regardless of melt index or density. There is reportedly no change in physical properties of the resin—“only a faster cycle,” says Thomas Wyszynski, technical manager for rotational resins. Schulman’s testing revealed that BPF technology reduced an 18-min cycle for one part to 15 min while attaining similar tensile properties.

News in mold monitoring

A new low-cost, entry-level mold-temperature data logger was introduced by 493K, a supplier of temperature and pressure measurement products for rotomolding. The U.K. company is represented here by Ferry Industries, Mity-Lite, and STP.

The K-Log device is a one-shot, one-channel temperature logger. The portable, camera-size unit is heat-insulated so it can be fastened to the mold with simple cable ties. The data from one complete molding cycle is collected with thermocouples and stored in the data logger. The device is then removed from the mold and connected to a PC to download the data. K-Log operates at up to 572 F and is said to be accurate to ±2° F.

The company also announced that its K-paq real-time pressure and temperature monitoring system has been upgraded to handle up to 12 machine arms with multiple molds. The system mounts on the mold and measures mold temperature with thermocouples in the mold wall and mold pressure via a sensor in the vent pipe. Data from the molding cycle is sent wirelessly in real time to the K-paq receiver and to a computer for display. The system operates at temperatures to 662 F. The firm says mold monitoring can trim heating-gas use 8% to 10% and reduce scrap up to 20%.

Meanwhile, Datapaq introduced Insight software for its Rotopaq real-time oven-temperature profiling system. The system includes a data logger, thermal barrier, and thermocouples. It attaches directly to the mold and sends data wirelessly to a receiver attached to a PC. The Windows software reportedly delivers fast download, analysis, storage, and printing of reports that can be exported to Microsoft Excel. Software “wizards” guide the user through basic setup of an oven profile and entry of product recipes and production templates. The system allows comparison of different runs.

With the new waterproof thermal barrier, data can now be collected and analyzed from molds with water-spray or mist cooling. RotoPaq can withstand up to 575 F for up to 3 hr.

Mold without the oven

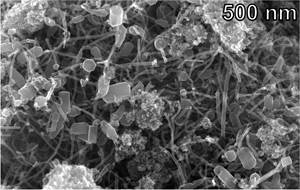

A new ovenless molding concept in which the mold is electrically heated via a conductive coating was unveiled by Innovex Systems (formerly reSource, Inc.), a supplier of custom machinery and automation for material preheating and dispensing, mold clamping, and parts removal. Its new HeatPaint Rotomolding system heats and cools the part without an oven or cooling chamber. The mold is painted with a new nano-particle conductive coating that receives current via slip rings that carry the power to the mold. The coating can be heated to 400 F in 30 sec, says sales manager Dirk Yerian. The coating reportedly can take continuous use at 650 F and short heat cycles at 850 F. Only the mold gets hot, so a center spider arm can carry electronic controls that send real-time data to the operator.

Innovex test-molded parts of 0.220-in. wall thickness in a 5.5-min heat cycle using preheated LLDPE powder and 6.5 min using cold powder. This compared with a cycle time of 12 min for the same part in a conventional machine. Energy cost for heating the mold was about 1.08¢ vs. around 11.5¢ with conventional gas heat.

Innovex is developing a fully automated system that includes automatic mold charging with preheated material. PC software will provide zoned temperature control of the mold and data acquisition. A lab machine will cost around $10,000 for the basic unit without molds.

More machinery news

The TRM swing-arm series from STP Rotomachinery has been upgraded with a redesigned combustion chamber, burner, and fans that improve hot-air distribution and heating efficiency. The series has also been redesigned for ease of maintenance. Also, the company is moving its manufacturing operations to a larger plant in the Sherbrooke, Quebec, area. The new site will help trim lead times to 12 to 16 weeks.

Larger parts can now be made on the XT line of dual-shuttle machines from Rotoline Industrial Equipment Ltda of Brazil, represented here by Reduction Engineering. The machines’ unique cylindrical oven is now about 10% longer, which is said to increase productivity and energy efficiency by eliminating dead or cold spots. The system reportedly provides 30% more output than a single carousel, and can use 20% to 25% less gas for heating than competing equipment while delivering up to 20% shorter cycle times.

A larger-capacity Mega-Mill material pulverizer was introduced by Powder King. Its new PK-DD Mega model can process 1700 to 2100 lb/hr of PE. The unit’s direct drive eliminates floor plates, belt guards, and the bearing housing assembly used in belt-drive models. It also delivers 10 hp more power than the belt-drive version.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More