Process Simulation Advances For Stretch-Blow Molding

Blow Molding

The challenges in molding simulation multiply along with the process complexity, making injection stretch-blow molding one of the most challenging areas to tackle. But one group is becoming a world leader in modeling ISBM and developing tools and hardware for process and product development.

Computerized process simulation has become an indispensable technique in injection molding but is still quite rare in blow molding. The challenges in molding simulation multiply along with the process complexity, making injection stretch-blow molding (ISBM) one of the most challenging areas to tackle. But those difficulties have not stopped the Advanced Materials and Processing group at Queen’s University in Belfast, Northern Ireland, from becoming a world leader in modeling ISBM and developing both software tools and hardware instruments for process and product development.

Starting in 1991, Queen’s University’s School of Mechanical and Aerospace Engineering received funding from the U.K. Research Council with the goal of removing all the typical trial and error from the ISBM process. “This started as a three-year project, but 20 years later we’re still working on it, although with a far more sophisticated toolset,” says Dr. Gary Menary, senior lecturer in the engineering school.

He started out as a mechanical engineering student at Queen’s, where he received his Master’s degree in computer-aided design (CAD), specializing in polymers. He stayed with the University as the advanced materials department developed its ISBM expertise and earned a Ph.D. in modeling the process. He became the ISBM team leader in 2003.

From the start, the research team collaborated with industrial manufacturers, including a local Irish company, Coca-Cola in the U.S., and a bottle development project that involved 16 European partners in an academic/industrial partnership. “We have conducted research with several billion-dollar U.S. companies,” says Menary. “Our industrial collaborators have helped keep us on track, giving us real-world feedback on what we are trying to accomplish.”

NEW INSTRUMENTATION & TEST METHODS

The primary simulation tool at Queen’s is the Abaqus finite-element analysis (FEA) software from Simulia, an application of Dassault Systèmes of France (U.S. headquarters in Providence, R.I.). “Even before I arrived, the department had benchmarked different software packages to see which was the most capable for nonlinear FEA, and Abaqus won out,” Menary says. “As our analyses of the ISBM process became increasingly sophisticated over the years, so did the software’s capabilities.” For example, “Abaqus gave us the ability to code our own material models and customize our analyses.

“One of the major difficulties faced by previous researchers in modeling the ISBM process was the inability to fully represent the deformation behavior of the PET polymer,” Menary notes. “Prior work definitely advanced the knowledge base, but we developed our own tests to provide validated data on which we could confidently build our library of Abaqus FEA models.”

Earlier models that the Queen’s group evaluated all made a critical assumption—that the air pressure inside the preform remained uniform as it inflated. “But our experimental observations showed us how much process conditions changed during inflation, greatly affecting the properties of the final bottle,” says Menary. “As the PET material expands, pressure inside the membrane is not uniform. It varies depending on the rate of air flowing into the system as well as the concurrent expansion of the membrane.”

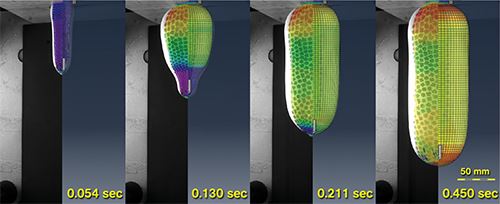

The changing pressure phenomenon is difficult to observe inside a closed mold. So the group utilized “free blow” without a mold. “Blowing without the mold enabled us to fully visualize the development of the preform,” Menary explains. Using a high-speed camera and digital image correlation, the engineers inflated a preform with a pattern applied to it, in order to track the expansion of the material (see photo sequence).

Data from these free-blow experiments were used to calibrate Abaqus FEA models for a more realistic simulation of bottle inflation response to fluctuating pressure. The team compared empirical test data to simulation predictions for the commonly used direct-pressure-input method versus the constant-mass-flow-rate method. The latter, available in Abaqus, calculates pressure based on the volume of gas in a cavity over time. “The mass-flow-rate method was much more appropriate and accurate for modeling pressure input in our ISBM simulations,” says Menary.

With a clearer understanding of the role of pressure from their validated free-blow models, the Queen’s engineers have turned to simulating the process inside the mold, including the all-important role of the stretch rod. “The sequence of stretch-rod movement and the onset of the pressure are key to controlling proper distribution of material in the process,” Menary says.

“There are still things we don’t fuly understand, such as the contact issues between the PET and the mold, and heat-transfer conditions,” Menary adds. “When the hot polymer touches the cold mold there is heat transfer as well as frictional behavior. There’s also temperature-dependent slippage between the polymer and the mold. All of these are the focus of our simulation work at the moment.”

Menary’s vision is to link everything together with simulation, from bottle and preform design and process conditions to thickness distribution and mechanical properties. “The data from the manufacturing process simulation can then be transferred to virtual packaging tests where you can see how the preform design affects things like bottle drop or topload performance, or even shelf life. You could couple this with optimization software like Isight (also from Simulia) to pinpoint optimum process conditions or minimum material usage.”

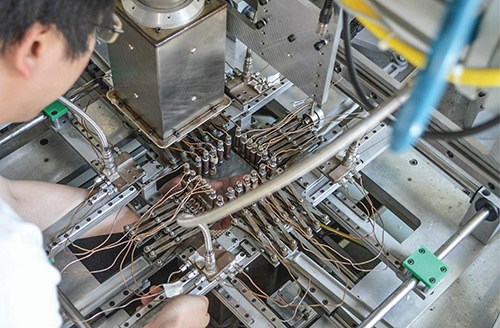

Besides validated simulation software tools, the Queen’s research has come up with its own testing hardware, such as a biaxial stretcher for materials characterization (photo p. 19). Two devices have been commercialized through a spinoff company, Blow Moulding Technologies. It sells instrumented stretch rods and the patent-pending Thermoscan device for preform temperature monitoring.

Released in 2011, Thermoscan is a laboratory benchtop instrument that measures the external and internal temperature along a heated preform. Thermoscan units have been sold to two of the largest U.S. bottle blowers, Menary says. Blow Moulding Technologies also offers simulation services and biaxial stretch testing of preform designs.

“We now have a multinational industrial collaborator that is using our current software tool to optimize its preforms and containers and troubleshoot production problems,” Menary says.

For the future, he sees new materials challenging his group. “We have a pretty good handle on the behavior of PET right now. Next we may turn to modeling the new plant-based plastics.”

Related Content

Adding Remote Service Functions for PET Bottle Blowing

KHS has added features to its internet machine communications portal for PET stretch-blow molding.

Read MoreCoca-Cola Europacific Transitions to Tethered Caps and Lighter PET Bottle

Sidel is converting all Coca-Cola PET bottling lines in Europe to meet new EU packaging regulations by July 2024.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreCoca-Cola’s Redesign of Small PET Bottles Pushes Lightweighting Below Prior ‘Floor’

Coca-Cola thought it had reached the limits of lightweighting for its small PET carbonated soft drink bottles. But a “complete redesign” led to a further 12% reduction.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More