Process ‘Upcycles’ Waste Plastics To Virgin-Quality PET

Depolymerization technology developed by Loop Industries aims to repurpose scrap PET of all types.

Like so many technology start-ups, it began with a vision and in a garage. Three years later, Loop Industries’ vision of turning post-consumer PET into virgin-quality material as a result of technology developed in that garage has become reality. The firm’s proprietary “upcycling” process breaks waste PET down to its chemical building blocks, separating out any impurities such as dyes, additives, and foodstuffs. These building blocks are then combined to create virgin-quality PET that can be used in food-grade plastic packaging.

Daniel Solomita, founder and CEO of Loop, was working on a landfill reclamation project in South Carolina, recovering tens of thousands of tons of waste plastic that had been abandoned years before. While taking steps to market the recovered material for recycling, he met a chemist in Quebec who was in the early stages of developing a chemical technology to upcycle waste plastic into virgin-quality PET.

The sheer number of inbound calls we continue to receive is exciting and a testament to the demand for upcycled plastic by consumers and companies alike.

From March to September of 2014, they worked out of Solomita’s garage, perfecting the technology and developing its commercial potential. The result was the launch of Loop Industries in 2015. Loop has since moved from the garage into an industrial pilot plant north of Montreal, with about 30 employees. The pilot plant was built to optimize and demonstrate Loop’s proprietary depolymerization technology in continuous operation, in preparation for the company’s ramp-up to large-scale commercialization.

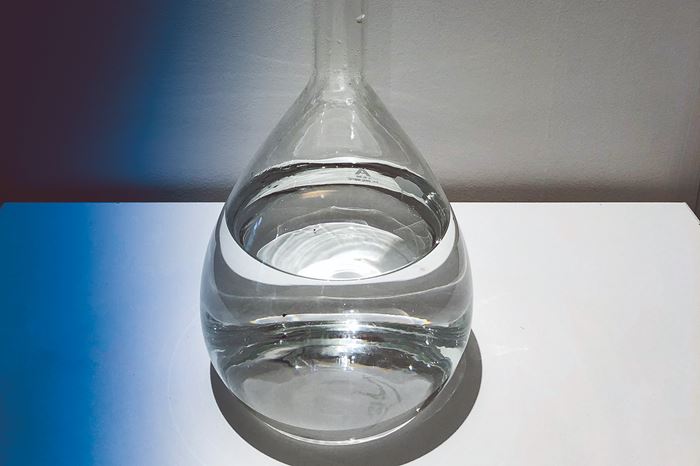

In its process, waste PET and polyester of all types, shapes and colors is brought to the company’s facility from sources like old t-shirts, fabrics, water bottles and food trays. Through the company’s depolymerization technology, the feedstock is completely broken down into its monomers: dimethyl terephthalate (DMT) and monoethylene glycol (MEG)—without adding heat or pressure. The monomers are then purified, removing all coloring, additives, and organic or inorganic impurities.

From there, the DMT and MEG are repolymerized into Loop-branded PET that meets FDA requirements for use in food-grade packaging. Loop-branded polyester resin allows consumer-goods companies to meet and exceed their stated sustainability goals and circular ambitions, the company says.

This past summer, Loop announced the next generation of its upcycling technology. Loop’s Generation II technology is significantly more streamlined and efficient than the Generation I process, including a considerable reduction in energy use and the complete elimination of water. The most significant change introduced in the Generation II technology is Loop’s decision to produce a monomer from DMT rather than terephthalic acid (PTA). Nelson Switzer, the former chief sustainability officer for Nestle Waters North America, who joined Loop Industries this year, says this move eliminates steps required to produce PET and requires less equipment and reduced amounts of chemicals, energy and resources.

In the next step toward commercializing its Generation II technology, Loop is designing a fully integrated manufacturing facility to upcycle waste PET and polyester fiber into virgin-quality resin and fiber. Loop is in the process of engaging engineering partners to complete the integrated design.

The growth plans include development of facilities strategically located near urban centers where both feedstock (waste PET) and manufacturers (bottlers) are found, Switzer says. Solomita says that these facilities will make it possible for all forms of waste PET and polyester fiber—even ocean plastics that have been degraded by the sun and saltwater—to be fully recovered and upcycled into PET “of the highest purity and performance quality.” This integrated manufacturing design will be the basis for Loop’s commercialization strategy.

WORK WITH MAJOR CONSUMER BRANDS

At the start of 2018, Loop announced a strategic initiative with evian—as part of a long-term Danone global partnership—to enable evian to meet its goal to have all of its water bottles made from 100% recycled plastic by 2025.

Loop has also signed a letter of intent with L’Oréal Group for Loop to supply L’Oréal with Loop PET resin in the U.S. and the European Union before the end of this fall. And Loop has launched a new program that allows consumers of Gatorade, produced by a subsidiary of PepsiCo, to help upcycle used Gatorade Gx pods into products of greater value with Loop technology. When consumers order their Gx bottle and pods on gatorade.com, they can elect to receive the free Gx/Loop mail-back pouch.

Consumers drop their used pods into the pouch, seal it once full and drop it in the mailbox. The pre-paid pouch is sent to Loop’s facility where the PET segments of each pod are deconstructed into base monomers, purified and upcycled into new virgin-quality, food-grade PET.

“We’re in discussions with or have been contacted by virtually every segment of the consumer-goods sector from beverages to apparel to furniture,” says Switzer. “The sheer number of inbound calls we continue to receive is exciting and a testament to the demand for upcycled plastic by consumers and companies alike.

Loop’s technology and our approach to commercialization is helping demonstrate that the circular economy can absolutely be profitable and drive sustainability. That’s because when you buy Loop PET, you’re not just buying a pellet, like from a conventional PET company or rPET company; rather, what you’re buying is a branded sustainable proposition that fulfills the needs and demands of consumers, governments, investors, environmental groups and other important stakeholders. It’s an authentic commercial demonstration of your commitment to sustainability.”

Loop has launched a new program that allows consumers of Gatorade to help upcycle used Gatorade Gx pods into products of greater value.

Switzer says Loop is driven by its entrepreneurial culture and commitment to a sustainable and circular economy—one where the economy is prosperous and restorative. He says, “The fact is that PET is a wonderful product because its properties allow food to be preserved and transported safely and securely, among its other important uses. The challenge becomes when this material enters the natural environment, which it has, and is why plastic has become a persistent environmental issue.

We believe Loop’s technology can help solve this issue by diverting this material from landfills and our shared rivers and oceans so that it can be endlessly upcycled and repurposed. That is a big part of what we are bringing to market—the upcycled plastics economy—and it’s something no one has done yet.”

Related Content

Nova Chemicals Attains FDA Letter for Mechanically Recycled LLDPE

RLLDPE product will be marketed for applications including food packaging.

Read MoreStar Plastics Achieves ISCC Plus Certification

West Virginia-based custom compounder adds to its sustainability credentials.

Read MoreCoinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More