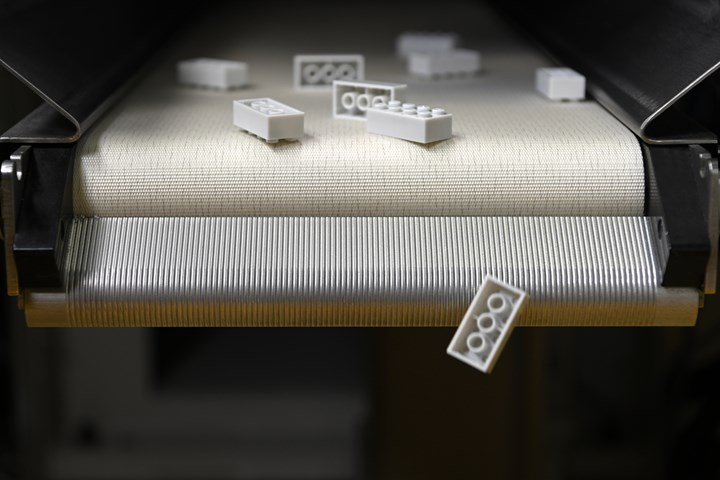

Prototype Lego Brick Made from Recycled PET

Proprietary compounding technology upgrades rPET with strengthening additives.

The new prototype Lego brick, which uses PET from discarded bottles, is the first brick made from a recycled material to meet the company’s strict quality and safety requirements.

Lego recently announced it has produced the first prototype brick made from recycled PET. Tim Brooks, v.p. of environmental responsibility for Lego, says that in 2015, the company set an ambition to make all of its products and packaging from more sustainable materials in the future without compromising on quality or safety. The company considers sustainable materials in this context, meaning materials from renewable or recycled sources.

Since 2015, a team of more than 150 people has been researching and testing a range of different renewable or recycled materials to see if they meet Lego’s strict quality and safety standards.

Overcoming Material Challenges

Recycled PET is one of hundreds of different recycled or renewable materials the team has tested and was selected due to its promising performance in safety and quality testing, according to Brooks. “Once we started to explore rPET, the team tested over 250 different variations of the material before we made the breakthrough with the patent-pending material formulation that we developed to make the material durable enough for Lego products,” he says.

The rPET is sourced from suppliers in the U.S. that use U.S. FDA and European Food Safety Authority (EFSA) approved processes to ensure quality. On average, a 1-liter PET bottle provides enough material for 10 “2 x 4” Lego bricks.

“When developing any new material, we need to make sure we can source enough raw material to meet our requirements,” Brooks notes. “We are confident that this will be the case with recycled PET and will continue to work on securing long-term supply.”

The patent-pending material formulation increases the durability of PET to make it strong enough for Lego bricks.

While there is plenty of rPET out there in the world, it’s not simply a drop-in solution. Brooks says Lego needs to invent entirely new materials for its products, as existing sustainable materials do not meet the company’s safety and quality requirements.

“For us, the challenge comes from needing materials that can be molded to the accuracy of a hair width to ensure bricks produced today fit with those made over 60 years ago, while being durable and safe enough to be handled by children day-in, day-out. At any one time, our expert team usually has around 30 different materials in various stages of development—this can include the prototyping stage if the raw materials pass our initial quality and durability tests.”

Lego has joined forces with universities and other pioneering companies to share knowledge, technology and research that will help sustainable material innovation generally.

“The challenges we face in the area mean we are really proud of the recent breakthrough that has allowed us to make recycled PET strong and durable enough for use in Lego products.”

One key innovation is that the company developed a patent-pending material formulation that increases the durability of the recycled plastic to make it strong enough for Lego bricks. Brooks says the process uses an innovative compounding technology to combine the rPET with a proprietary mix of strengthening additives. Lego is working with an R&D partner in the U.S. who applies this process to rPET granulate that has been cleaned and safety tested.

“The PET we make the prototype brick from has been enhanced to fit the purpose of a Lego brick with all the safety and quality requirements that come with it,” Brooks states. “That means we can’t apply conventional recycling methods for PET bottles to recycle these bricks. However, a number of more advanced recycling technologies are in development that may offer potential solutions to recycling PET bricks in the future.”

Next Steps

It will be some time before bricks made from a recycled material appear in Lego product boxes. The team will continue testing and developing the rPET formulation and then assess whether to move to the pilot production phase. This next phase of testing is expected to take at least a year.

“We still have further testing to do before we could consider including it in boxes—we need to work out how best to color this material and mold it into different shapes. For now, it’s showing good promise, but we plan to refine the prototype and material for at least another year before we assess whether we can move into pilot production.”

Currently the prototype recycled plastic Lego brick is light gray because Lego has not yet added colors to the prototypes. One of the next steps in prototype development is ensuring the material can be colored in the shades required for Lego products.

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More