Putting Industry 4.0 to Work in a Molding Plant

Learn why—and how—innovative molders have begun to develop “smart factories,” using advanced equipment, IT, and communication technology to enable greater connectivity and productivity.

Computer integration of plastics processing operations has been in the works for some time. For example, as early as the K trade fair in 1986, Arburg presented a fully automated production system consisting of several interlinked injection molding machines that used central computer control to almost eliminate manual setup. This system, which included an early version of the Arburg host-computer system, was referred to as “Computer Integrated Manufacturing” (CIM), a basic first step toward what is called today “Industry 4.0” or the “fourth industrial revolution.”

Computer-integrated manufacturing” (CIM) of the 1980s and ’90s was an early first step toward Industry 4.0.

Equipment design and information and communication technology have advanced considerably over the last 30 years and have made it possible to imagine ever more complex processes to meet demand for greater productivity.

These systems need to be flexible and easily manageable; increasing pressure for efficiency and the shortage of skilled technical employees argue loudly for more automation and equipment that operates with a minimum of human intervention. This, in turn, increases the

importance of tight integration of elements like machines, robots, other peripherals, and host-computer systems in the production process, using today’s advanced communications and connectivity technologies. Some of the most innovative molders are already taking advantage of these Industry 4.0 technologies to add value, increase producion efficiency, and enhance process reliability.

PUTTING INDUSTRY 4.0 TO WORK

The typical injection molding plant today is focused primarily on producing parts of sufficient quality while limiting costs. To that end, the processing staff studies current operating conditions and identifies problems so that the process can be optimized and molding capacity can be utilized most effectively to ensure a healthy profit.

Molders who embrace the broad concept of Industry 4.0 follow these fundamental practices too, but they need to be able to adjust and control the production process, however complex, intuitively without requiring specialized knowledge. The aim is to use “smart” machines that integrate peripherals with ease, analyzing and regulating process parameters, centralizing data management, and providing far-reaching assistance and support functions. There is still quite a long way to go before we achieve those objectives completely, but progress is being made every day.

As a technology and systems provider, Arburg has worked on several turnkey systems that involve not only injection molding machines and robotic systems, but also central monitoring and control of both injection machines and peripherals to capture process data and provide part-specific traceability.

For instance, Plastikos Inc., a world-class custom molder in Erie, Pa., uses integrated Arburg molding machines and robots. In one complex medical application producing around

4 million parts per year, ABS parts are produced in a first step in one press. The parts are picked up by a linear robot controlled by the injection machine control system. The robot places them in a second press to be overmolded with TPU, and then removes the finished parts. This automated sequence saves valuable cycle time. The molds are equipped with cavity-pressure measurement systems, as well as thermographic and visual camera systems for continuous quality monitoring.

“Our machines work around the clock, five days a week,” says Robert Cooney, Plastikos manufacturing manager, “and we can also continue on the weekend if necessary.” Using a host- computer system from Arburg, he adds, “We record the machine parameters necessary for quality control and documentation and archive all data sets. Thanks to this system and cavity-pressure measurement throughout our production, we can monitor quality and efficiency on an end-to-end basis and respond well in advance before reject parts are produced.”

Another example is Vorwerk & Co. KG in Wuppertal, Germany, which uses two Arburg turnkey systems in production of bearing shafts that are key components in the company’s Thermomix multifunction blenders. The cells are built around two vertical injection machines with four-cavity molds, one of which operates with a rotary table. The systems also include a six-axis robot, an insert feeder, and a preheating and transfer station. The robot is the central handling device in the cell, picking up shaft inserts from the preheating station, placing them in the molds, removing the overmolded shafts, and depositing them in pallets at the transfer station. Electric barriers at the clamping units ensure that the robot is out of the way before the molds close. A single human operator loads empty pallets and removes full ones.

JUST THE BEGINNING

The highly automated turnkey systems at Plastikos and Vorwerk allow these molders to produce critical precision components quickly and cost-effectively. Given this integration of upstream and downstream operations, the combination of injection molding and other processes, with centralized control and process monitoring via a central host-computer system, these companies can be said to be well on their way to implementing Industry 4.0. However, in reality, even these innovative molders have only begun to open up the full potential of Industry 4.0.

During the Technology Days open house in March of this year, Arburg demonstrated several potential applications of Industry 4.0 technology in production of “smart” luggage tags. It involved sequential manufacturing at spatially distributed locations, mass customization of high-volume parts through the combination of injection molding and additive manufacturing, as well as the end-to-end traceability of individual parts using a host-computer system.

The operational sequence began at a turnkey production cell where an injection molding machine and six-axis robot teamed up to produce luggage tags in high volumes. At the end of each molding cycle, the robot removed two half shells, inserted an NFC (near-field communication) chip, and then assembled the body of the tag.

Next, the individualization information—the identity of the owner and the graphic motif of the tag—was transferred from an input terminal to the NFC chip in the luggage tag. Thus, the part itself became an information and data carrier, identifying itself at the various stations and directing subsequent produc- tion operations. Each luggage tag was also assigned its own website in the cloud.

Individualized production—or “mass customization”—is one way in which Industry 4.0 can permit new modes of manufacturing.

At the next station, the personal information of the owner— name, address, phone number, etc.—were laser etched onto the tag in plain text and as a QR code. Then, the decorative motif previously selected and recorded on the NFC chip, was applied by Arburg’s Freeformer industrial additive-manufacturing (3D-printing) system. Finally, end-to-end traceability was made possible when the finished tag, with its integral NFC chip, was used to direct the central host computer to transfer all process and quality data related to its individual website in the cloud. From there it is available on any digital device at any time.

This production sequence may seem relatively simple, but it encompasses a number of important and complex concepts, all of which can be part of Industry 4.0.

The molding cell demonstrates the integration of multiple pieces of equipment autonomously producing a finished component (tag with integrated chip). The product itself manages and controls its own manufacturing process. In this case, it was a molding machine and robot, but as the applications at Plastikos and Vorwerk showed, the cell could have included insert feeders, quality inspection equipment, packaging systems, and much more.

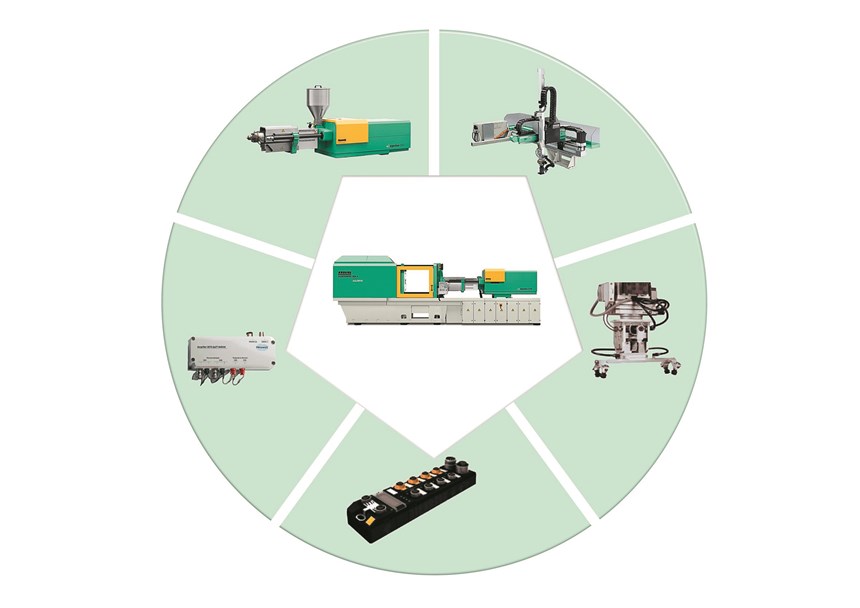

Key elements of Industry 4.0 are integration of peripheral equipment through the injection machine control, and networking of the press control to a central host computer.

Instructions required to produce a uniquely individual product (batch size of one) were entered offline and transferred to the manufacturing equipment via the NFC chip. In other words, the product itself communicated the information needed to direct its own manufacture, through several different operations at various processing sites.

Process and quality data from the manufacturing of each unique product (luggage tag) was gathered and stored so that it is immediately accessible using information in the product itself. This ensures 100% traceability.

IT NETWORKING AND ‘BIG DATA’

The key to efficient regulation and control of machines, automation, and the entire manufacturing process from an Industry 4.0 perspective is the IT networking of production with a high-performance manufacturing execution system (MES) that is directly connected to a company network. This allows molders to collect, process, analyze, and archive all relevant data on the job, machine, setup, process, and quality.

In the Arburg ALS host computer, this “Big Data” can be displayed in three information areas: Machine Status (operating modes, alarms, and fault causes), Operating Data (parts counter, program, mold, and order information), and Process Parameters (actual values from the molding cycle).

STANDARD INTERFACE FOR DATA EXCHANGE

Arburg is currently working with other controller and software developers from leading injection machine manufacturers on the new Euromap 77 standard, which seeks to establish a uniform international host-computer interface for two-way exchange of data between injection machines and MES. The host computer can initiate a job by loading it into the machine control system. Conversely, job-specific parameters relating to the machine and automation components integrated in the process are reported back to the host computer.

Simple, standardized networking of machines and peripheral components enables even faster and more efficient data exchange between the molding machine and the host-computer system. Compared with Euromap 63, which it will replace, Euromap 77 is much more flexible. It will encompass not only standard injection machines, but also multi- component and rotary-table machines, and even individual injection units, as required.

ON THE WAY TO THE ‘SMART FACTORY’

The eventual integration of information technology in “smart” machines could change plastics processing to the same extent that the smartphone has changed everyday life in recent years. However, unlike a smartphone, Industry 4.0 is not an off-the-shelf product.

Plastics processors do not have to set up a fully networked “smart factory” overnight in order to launch Industry 4.0 in their company. Instead, they can evaluate the concepts and technologies behind it individually, develop a strategy that suits their company’s unique competencies and operations and process requirements, and implement it gradually.

Many small and medium-sized companies have already started this journey towards Industry 4.0 and are implementing some aspects of it. For example:

• Production planning using a host-computer system;

• Modern molding machines with position-regulated screws and programmable pressure control for process stability and quality assurance;

• Flexibly automated and networked turnkey systems;

• Machine assistance systems like a menu-guided setup program.

The digital factory of the future will control and optimize itself. In other words, production data will no longer be managed centrally, but will be displayed and evaluated on a mobile, decentralized basis, via tablets and other smart devices. Human beings will monitor processes and sequences and intervene only as necessary. “Mass customization”—the individualization of high-volume parts—will become relatively simple and cost-effective. This will require a high degree of automation and extensive networking of order information, machines, molds, and logistics. Individual machines and systems must be well coordinated with standardized interfaces and data protocols before all this is possible.

In reality, we really don’t know yet what Industry 4.0 eventually will become. In this article, we have examined some of the elements that already exist, and we can imagine what will be possible as these technologies are refined and implemented. However, it will be up to plastics processors to tell us what they need Industry 4.0 to be.

ABOUT THE AUTHOR: Christoph Schumacher is head of global marketing for Arburg in Lossburg, Germany. A communication expert with a Ph.D. from Aachen University, he has a strong technical background, thanks to nearly 20 years’ experience in plastics, most of them with Arburg. Contact: contact@arburg.com; arburg.com.

Related Content

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More