Recycling: What's Ahead in Advanced Sorting Technology

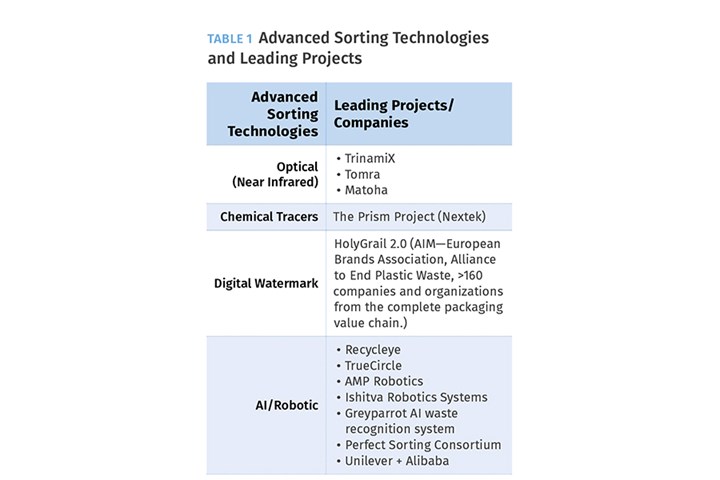

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

To enable the detection of black plastics, Tomra’s Autostart combines multiple technologies in one sorting machine, including NIR, laser, electromagnetic, and AI-based camera sensors. (Photo: Tomra)

Reports published almost daily refer to the abysmally low plastic recycling rates, with the national average in the U.S. and globally still hovering around the single-digit mark. While the corresponding data from the European Union is definitely higher, it’s safe to say that a lot of work is still needed and that there is no “silver bullet” to tackle this issue. Several coordinated actions, already on the move, are required to accelerate scale-up of recycling rates.

Advances in recycling technologies—be they mechanical or chemical —are underway and their complementary implementation is crucial to widening the pool of high-value recyclates. Equally important will be steps taken during the complete lifecycle of the plastic product—starting from design for recycling (before the product hits the market), further reuse while in circulation, and finally, wide-spread collection and enhanced sorting at end-of-life.

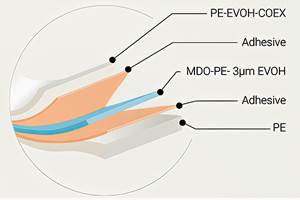

The plastic waste issue is multi-dimensional not only because of the large volume that needs to be dealt with, but also due to the wide variety of plastic types (polyolefins, polyesters, styrenics, vinyls, and specialty polymers) and plastic product designs (rigid, flexible, multilayer). This diversity makes recycling them a challenging task—one that can be overcome with a “toolbox” of recycling solutions. To significantly improve the recycling rates and also the quality of recyclates, it is also important to ensure advanced sorting of mixed plastic waste into high-quality mono-waste fractions.

The good news is that the industry has taken up this challenge and there are several innovative solutions in the offing—ranging from enhanced optical sorting technologies to advanced solutions based on digital watermarks, and artificial intelligence (Table 1).

The Nextloopp technology project aims to create circular food-grade PP from PCR packaging and is based on high-speed precision sorting using Nextec’s invisible PolyPrism fluorescent markers.

Photo Credit: Nextec

Expanding the Scope of Optical Sorting

Near-infrared (NIR) is a proven technology that uses a hyperspectral camera to identify and sort specific polymer types. However, there are certain limitations such as the inability to detect inner layers in the case of multilayer packaging, plastic with carbon black pigment, low levels of contamination, and very thin coatings.

Research institutes and industry players are working on solutions to improve this technology to enhance the quality of the sorted fractions. Earlier this year, Danish researchers from Aarhus University in collaboration with Vestforbrænding, Dansk Affaldsminimering Aps and PLASTIX shared an update regarding a new NIR camera technology that can distinguish between 12 types of polymers: PE, PP, PET, PS, PVC, PVDF, POM, PEEK, ABS, PMMA, PC, and nylon 12. This technology, tested at pilot scale, can allow separation of plastics based on purer chemical composition (polymer type) than is possible today, further improving the recycling rate.

Efficient separation of nylons 6 and 66, which have similar properties, has also been a challenge that was recently addressed by trinamiX, a wholly-owned German subsidiary of BASF. Its hand-held mobile NIR spectroscopy solution combines robust hardware with intelligent data analysis and a mobile app to distinguish between the two polymer types.

Another interesting portable unit that uses NIR has been developed by the U.K’s Matoha. Its easy-to-use PlasTell device reportedly can identify all the common polymers such as PET, PVC, PE, PP, PS, ABS, PC, nylons, PMMA, PLA, and PU. Specialty plastics or polymers can be added upon request. However, thin films (<20 microns) and plastics containing carbon black cannot be identified by this product.

To enable detection of black plastics, Tomra, a leading manufacturer of sensor-based sorting systems, has developed add-on laser sensors. Its Autosort technology combines multiple technologies in one sorting machine—including NIR spectroscopy, laser, electromagnetic, and AI-based camera sensors.

Tomra is also a partner in the Nextloopp project, which aims to create circular food-grade recycled PP from post-consumer packaging. The technology behind Nextloopp is based on high-speed precision sorting of packaging using Nextek’s PolyPrism fluorescent markers. In sorting trials conducted with Tomra, 99.9% purity was achieved at full speed using NIR/VIS sorting equipment.

Digimarc’s digital watermarking technology as part of the advancing HolyGrail project reportedly improves sortation accuracy, efficiency, and precision. (Photo: Digimarc)

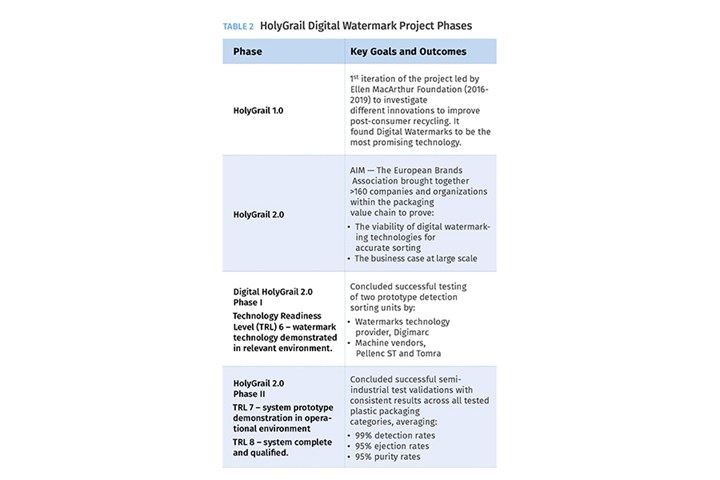

Digital Watermarking: The ‘Holy Grail’ of Sorting

The project HolyGrail 1.0, initiated in 2016 by a consortium that now numbers more than 85 European companies across the consumer packaging value chain, has been advancing to new phases of its Digital Watermarks Initiative. Digital watermarks are essentially barcodes the size of a postage stamp that are unnoticeable to the naked eye. These are printed repeatedly to cover the surface of a package. They encode a wide range of attributes, including the materials of construction. Once the used package enters a waste-sorting facility, the digital watermark can be detected by a standard high-resolution camera on the sorting line. Based on the attributes “read” by the camera, the package could then be more accurately sorted than by current technologies, such as NIR spectroscopy, which cannot reliably identify multi-material structures.

Digital watermarks offered by companies such as Digimarc, Beaverton, Ore., a recognized global leader in product digitization, have been identified as perhaps the most promising technology to improve post-consumer recycling in HolyGrail’s 1.0 iteration. Meanwhile, HolyGrail 2.0 is approaching its third and final phase. Industrial-scale tests are planned to start before year’s end and their successful completion would bring the technology to the level of an actual system proven in an operational environment.

Digital watermarks have been identified as perhaps the most promising technology to improve post-consumer recycling.

Digimarc offers a secure, universally available, and covert identification technology, which reportedly improves sortation accuracy, efficiency, and precision. It does not impact the overall recyclability of the packaging and performs in the harsh conditions of waste sortation and recycling facilities. The watermark can be identified regardless of the position or orientation of the packaging, even at high sorting speeds. This technology also enables sorting machines to detect dark-colored & multilayer packaging and sort nonfood from food packaging. (Table 2).

The digital watermark requires no special inks, printing process, materials, or manufacturing process and can be applied in print, using encoder software that applies tiles to graphics over the entire surface by using existing pixels, or in the substrate, by embedding micron-height topological variations via engraved molds or laser texturing.

Together with SGK, a global packaging and brand-experience company, Digimarc tested another option of applying the code in the varnish only. The initial results are promising, as it can offer additional benefits such as allowing brands to preserve their original design and enabling standardized application for all artworks, removing the need for customization of the Digimarc application method.

Thanks to the QR codes, it is has already proven possible to use this innovative technology for consumer engagement as it can provide information such as product composition, usage, and recycling guidelines.

Unilever has partnered with Alibaba on the Waste-Free World initiative, whereby 20 recently installed AI-equipped recycling machines in two Chinese cities allow consumers to deposit bottles in recycling bins; and the AI technology identifies the bottle’s plastic, sorts it and stores it so that it can be collected and returned to recycling centers and fast-tracked for reuse. (Photo: Unilever and Alibaba)

AI-Based Waste Sorting

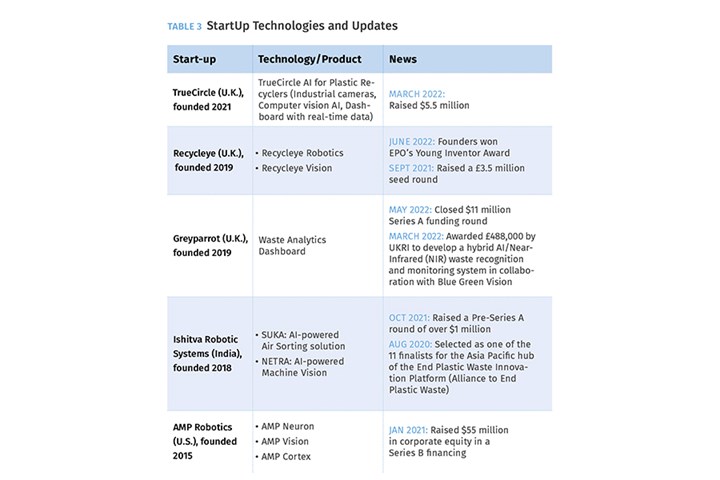

The past couple of years have seen a flurry of startups designing innovative solutions based on artificial intelligence (AI) and machine learning to address plastic -waste sorting challenges. The AI models designed for waste sorting usually consist of three segments: computer vision technology (the “eyes”); AI learning (the “brain”); and sorting robots (the “hands”).

While all these technologies have already been used in industrial processes, advances in algorithms in recent years allow most of these models to offer greater granularity. They can identify multiple categories associated with plastic waste (e.g., plastic type, its weight, the brand, food versus nonfood). Many of the startups are also creating an end-to-end digital twin of the sorting process and providing customers access to customized dashboards that display real-time analytics (Table 3).

It’s not just the startups, though. Earlier this year, nine brand owners (including Danone, Colgate-Palmolive, Ferrero, LVMH Recherche, Mars Incorporated, Michelin, Nestlé, PepsiCo, and Procter & Gamble), along with an independent test & research center and two universities announced the launch of The Perfect Sorting Consortium. The goal is to apply their combined expertise over the course of two years to develop and test an artificial intelligence (AI) decision model.

Also, Unilever has partnered with Alibaba of China on a joint initiative called Waste-Free World. In this project, 20 recycling machines equipped with AI technology have been installed in Shanghai and Hangzhou, China. Consumers can deposit their bottles in the recycling bins and the AI technology automatically identifies the plastic in the bottle, sorts it, and stores it so that it can be collected and returned to recycling centers and fast-tracked for reuse.

Adopting AI-based sorting models can streamline and accelerate the waste sorting process, and material-recovery facilities can achieve high accuracy rates (>93% and up to 99% in some cases). This will further allow the recyclers to meet the growing demand for high-quality recyclates.

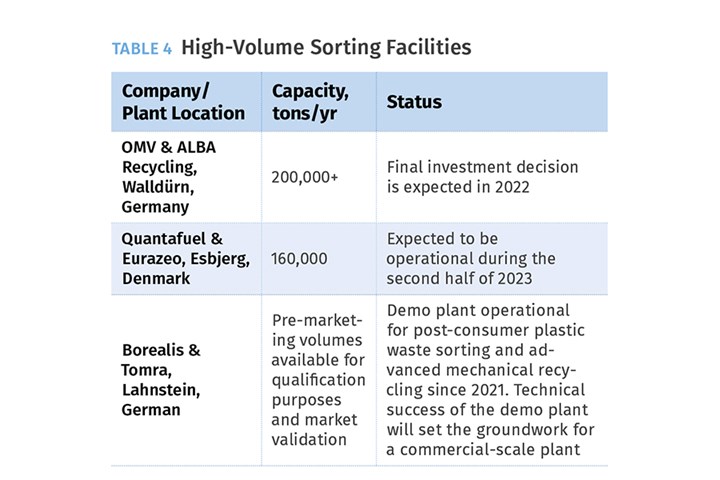

As the deadline to meet the challenging recycling targets approaches, the industry is looking to secure both good quality and sufficient quantity of sorted waste fractions. There have been a couple of noteworthy capacity announcements, with most of the plants expected to be operational in the next two-to-three years (Table 4).

ABOUT THE AUTHOR: Sreeparna Das is an independent consultant, communications and editorial specialist with a M.S. in chemistry and 13 years of experience in the specialty chemicals industry and digital media. Specializing in communication of sustainability topics within the chemicals industry, she advises leading brands and industry associations that support the transition towards a Circular Economy. She has published over 30 articles on topics related to advanced recycling of plastics, circularity of flexible packaging, carbon capture and utilization, the impact of the European Green Deal on specialty chemicals. Contact: sreeparna.das.pro@gmail.com or @SreeparnaDas20.

Related Content

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreRecycling Terminology Can Be a Minefield, So We Should Tread Lightly

Loose propagation of terms like “recyclable” and “compostable” has already brought down government regulations on labeling. The plastics and packaging industries should take that to heart with other recycle-related language. Like “monomaterial” for example.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MorePurpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreRead Next

Chemical Recycling Poised to Take Off

Investments in chemical-recycling facilities abound as the industry moves closer to the Circular Economy model, accompanied by plenty of new rollouts of packaging made from chemical recycling.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More