Davis-Standard Opens Expanded Plant, Buys Maillefer

Machine builders adds space to accommodate blown film die manufacturing.

Davis-Standard, has completed its expansion of 15,000 ft2 at its home base in Pawcatuck, Conn. And on July 17, Davis-Standard president and CEO Jim Murphy welcomed Connecticut Governor Dannel P. Malloy; Department of Economic Community Development (DECD) Commissioner Catherine Smith; Connecticut State Representative Diana Urban; Connecticut State Senator Heather Somers; Stonington Second Selectman Mike Spellman and more than 400 employees to celebrate the occasion with a ribbon-cutting ceremony.

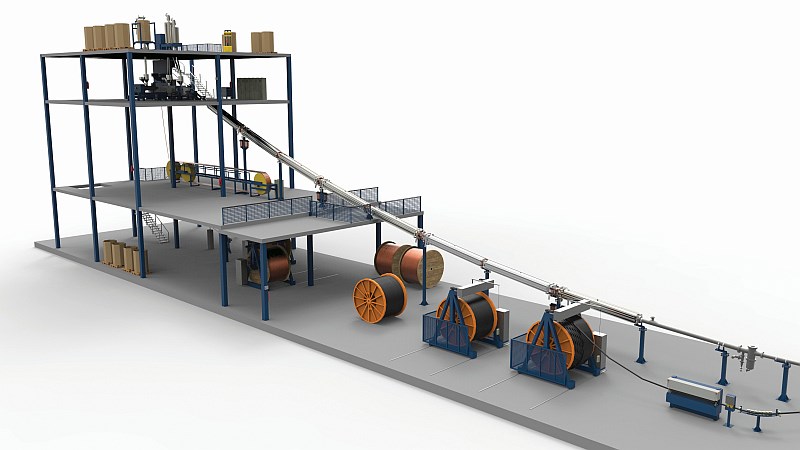

Meantime, D-S announced it had bought Maillefer International Oy of Vantaa, Finland and Ecublens, Switzerland. Maillefer is a global leader in wire, cable, pipe and tube production technologies (photo).

The new space houses manufacturing and precision machining of advanced multi-layer blown film dies, enabling Davis-Standard to move all blown film manufacturing from Gloucester, Mass., to Pawcatuck.

“The facility addition is the culmination of our vision to bring world-class blown film die production to Pawcatuck,” said Murphy. “All Davis-Standard blown film die technology is now integrated under one roof, making us one of the largest manufacturers of seven to 11-layer blown film dies in the world. These dies are used for making highly technical multi-layer films used in packaging and pharmaceutical applications, which are high-demand markets for us.

Davis-Standard has operated in Southeast Connecticut since 1848 and is one of the oldest employers in the Southeast Connecticut/Southwest Rhode Island region. The expansion will bring more than 30 new manufacturing jobs to the site over two years.

On the Maillerfer purchase, Murphy said, “Maillefer is a global leader that has built a strong brand based on operational excellence, technology, and providing superior customer solutions. We are excited to expand our organization with Maillefer’s talented workforce and outstanding management team.”

Related Content

-

New Rotary Die and Cam Lock Design for Tubing

NPE2024: New design enables quick and easy assembly and disassembly of the crosshead, and eliminates the socket head cap screws.

-

Updated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

-

Novel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.