Robots Play a Role in Industry 4.0

Robots are gaining the ability to monitor their internal systems for remote troubleshooting and predictive maintenance. They also are reporting production data.

If a show as big as NPE can be said to have a single overarching theme, this year the leading contender would be the wave of technological innovation and futuristic enthusiasm known variously as Industry 4.0 or the Smart Factory or the Internet of Things. That wave has charged across the ocean from Europe, where new protocols for machine-to-machine and machine-to-central-computer communications are being developed under the leadership of the German machinery association, or VDMA, as well as the European Plastics & Rubber Machinery Association, EUROMAP.

Although much of plastics machinery used here comes from Europe, the concept of Industry 4.0 has not achieved the same degree of familiarity on this side of the Atlantic. “Molders here are more at the stage of ‘What is it, and why do I need it?’ They want to know how much change it will bring to their operations, what it will cost, and how they will benefit,” says David Preusse, president of Wittmann Battenfeld, Inc.

Jim Healy, v.p. of sales and marketing for Sepro America, thinks that Industry 4.0 can be understood in part as an evolution of trends that have been developing for years. “If Industry 4.0 is about connectivity between machines, then robots have been ‘Industry 4.0’ for years, thanks to standardized control protocols. Today, that connectivity goes several steps further in automation cells that may involve not only a molding machine and a robot, but also insert feeders, secondary robots, complex end-of-arm tooling, in-mold sensors or vision systems, post-mold handling, inspection, finishing, stacking, and packing.”

Preusse advises show visitors to observe how exhibitors illustrate practical ways of using elements that tie into this new Smart Factories era. He said these can include:

• Molding cells with robot, press, and auxiliaries all connected together;

• Mold setup recipes for robots and other auxiliaries stored on the injection machine for

faster mold changes;

• Web service support;

• MES collection of production data;

• Smartphone apps to get production status or alerts;

• Predictive-maintenance monitoring of robots and other cell equipment;

• “Smart molding” process solutions;

• Production traceability;

• Remote access and control.

That’s an awful lot to digest, and Chris Parrillo, national sales manager of Yushin America, thinks the best way for molders—especially those from small to mid-sized firms—to approach the topic is to “break it down into manageable chunks.”

One of those chunks is predictive maintenance, which is an emerging theme that is being sounded at the show by injection machine suppliers and builders of auxiliary equipment. The idea is for a robot “to monitor its own internal systems and detect problems as they develop, so it can warn of a maintenance issue before a catastrophe strikes on a weekend shift,” explains Dino Caparco, Yushin’s engineering operations manager.

Some of early signs of this trend for robots are visible at NPE. For example, look for features such as monitoring gripper vacuum levels to warn of leaks or other problems before the robot loses its grip. Other approaches include vibration sensing and monitoring servomotor torque and amperage load to detect bearing misalignment, insufficient lubrication, damaged rails, and/or fatigue of the robot arm due to repeated flexing.

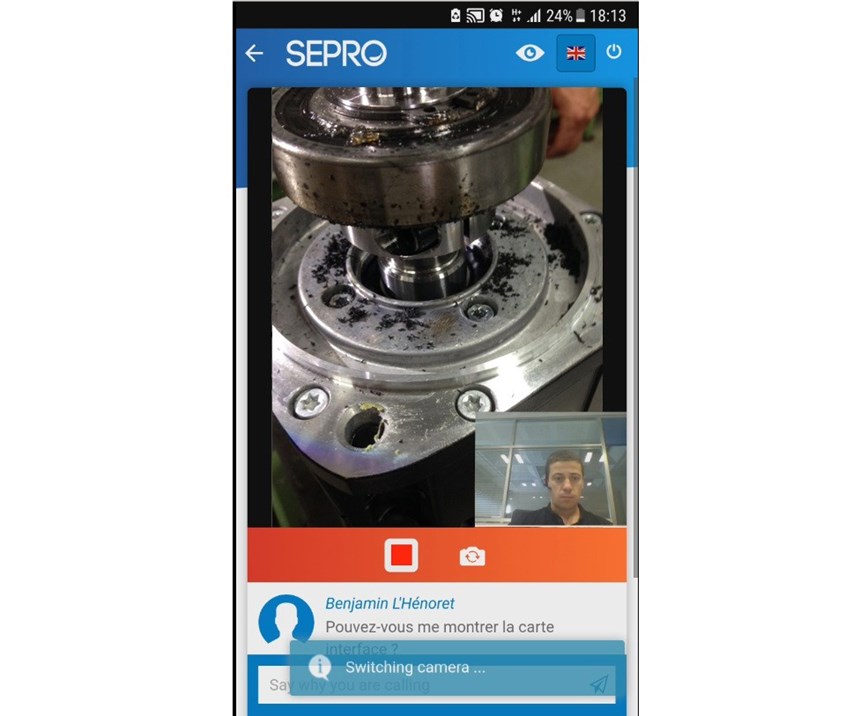

Another closely related “chunk” of Industry 4.0 is remote monitoring and web-service support. Such features have become increasingly common for molding machines and are now spreading to robots.

Still another related trend under the broad umbrella of Industry 4.0 is varying degrees of integration of robot controls with those of the injection press, which can range from “mirroring” of the robot control interface on the operator panel of the press to actual sharing of data between the robot and press—a more complex issue when different vendors are involved.

Related Content

Automation in Winding, Coiling and Cutting for Reduced Labor and Increased Safety and Consistency

Reel Power will demonstrate how its automatic winding system works in concert with extrusion and automated pick and place.

Read MoreEngel Teases Generative AI Assistant at Digital Days Event

The Austrian maker of injection molding machines and automation introduced a prototype large-language model assistant for its customers: Engel GPT.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More