Running Hot: Solutions for High-Temperature Injection Molding Cells

Here are some best practices for setting up and maintaining high-temperature injection molding processes, including sourcing and maintaining suitable water- and oil-circulating systems.

Specialized hoses, manifolds and valves are available for high-temperature molding applications.

Source: Plastixs

High-performance, engineered plastics — particularly in aerospace, medical and automotive — increasingly require higher mold temperatures than those used in traditional molding applications. These high temperatures are needed to meet the tight tolerance and high surface-finish requirements for parts molded from high-performance resins. In many cases, high mold temperatures are also required to ensure parts have the correct physical properties post molding.

Achieving high mold temperatures requires advanced high-temperature water- and oil-circulation systems, including water-circulation systems capable of running up to 445°F, with oil units up to 550°F. Both types of circulation systems pose challenges for processors, especially for those unfamiliar with operating molding cells with mold temperatures up to 450°F.

To protect your team and ensure optimal throughput when using high-temperature circulation systems, several issues must be addressed. In this article, we will focus on:

- Safety for personnel and plant operations

- The importance of a clean water supply for equipment and circulation loops

- Sourcing the correct system components

- Safe operation of molds running above 300°F

High-temperature circulation equipment must be treated with respect, and the installation of this equipment requires planning to ensure supporting components and materials meet safe operating requirements. Operational procedures for this equipment can be unique when compared to similar equipment running in a typical molding facility.

Equipment shielding, hose insulation and personal protection equipment (PPE) requirements must be considered to ensure safe operation of the molding cell on a busy production floor. Generally, circulation systems need guarding or shielding on the supply and return connections of the process manifolds to protect operators who work closely with these units. All high-temperature hoses going to and from the mold must be insulated to protect molding technicians who access the molding area, as well as for process stability and efficiency.

Mold insulation that isolates the tool from the machine’s platens is also strongly recommended to keep the platens from heating up and causing safety and operational issues. These materials must be the same type of insulation used on the hot runner side of the mold, but also installed on the tool’s ejector side. This insulation can be machined to size from a number of plastic industry sources.

For both high-pressure water and oil units, it’s imperative to avoid leaks of any size in the manifolds, valves, connections and hoses, otherwise serious operational issues can occur. This is why component selection related to this equipment is so important and discussed in its own section below.

For high-pressure water-circulation units, it’s important to understand that these systems circulate water instead of steam, even at 400°F or higher. With the help of controls and valving, these units generally operate 1 Bar above the vapor pressure of water so, for whatever the water temperature set point is, the water is always circulating as a liquid. This is important because it makes it very difficult to identify leaks. When a leak occurs, it’s released as steam because there isn’t enough pressure to keep it liquid. Compared to water, this steam can be difficult to see. As a matter of safety, steam loses heat quickly and is less likely to cause injury beyond approximately 1 to 2 feet of the leak.

On the other hand, oil units generally operate at low pressure, that is > 50 psi in most equipment. Heat-transfer oil, which is the only oil that can be used in these systems, has low viscosity at operating temperatures above 300°F. This can cause seepage leaks in any area of the system not tightened and sealed with the correct techniques.

These leaks can also lead to smoking as the oil degrades and the seepage is exposed to air. A major difference with oil versus pressurized water is that heat-transfer oil is an insulator, which can cause severe burns to exposed skin, regardless of distance from the leak point.

When operating at elevated temperatures, safety considerations are critical. The equipment and components that tie these units to the mold must be closely evaluated to ensure all high-temperature and pressure requirements are met.

The Importance of a Clean Water Supply

Many injection molders overlook water system quality, which has a direct impact on plant equipment and, ultimately, the ability to produce high-quality parts. It’s even more important when using water-circulation units operating at temperatures from 300°F to 445°F. A key feature that manufacturing engineers need to discuss with their equipment suppliers is the availability — either as a standard or optional addition — of a separate water supply for the temperature circulation unit (TCU). Ideally, one water supply is needed for the cooling water serving the heat exchanger, while another water supply is needed to supply the TCU and mold-filling circuit. It’s important to fill the mold-circulation circuit of these units independently from the plant water systems.

Here are some of the issues to identify and recognize when the plant cooling loop is used for both cooling the heat exchanger and filling the water circulation unit and the mold:

Glycol in Closed-Loop Chiller Systems

Closed-loop chilled-water systems are common in industrial processes because of their efficiency and ability to maintain consistent temperatures. A key ingredient in many of these systems is glycol, which serves as antifreeze to ensure the system remains operational in colder conditions.

However, when exposed to temperatures above 260°F, that glycol breaks down and transforms into a sticky gum-like substance. This not only restricts water flow, but it can also cause significant issues for the molding cell trying to run at high temperatures.

Solution: Use separate water supply systems for distilled water that can maintain pressure and supply the unit with enough water to fill the system, hoses and mold. Note: pressure must be maintained on the water inlet for the circulation system to run.

Potential Consequences

- Blocked Lines and Passageways: the gum-like residue from decomposed glycol can clog lines, valves and passageways, reducing flow rates and causing drastically reduced heat-transfer rates that reduce cycle times and impact part quality.

- Equipment Failure: the degraded glycol will cause major issues with the sensitive valves in this type of circulation system, leading to system failures and causing undue stress on pumps, which in turn degrade seals and cause expensive repairs.

- Reduced Heat Transfer Efficiency: the insulating properties of the decomposing glycol can inhibit heat transfer, causing systems to work harder to achieve desired temperatures, which leads to increased energy consumption and decreased product quality.

- Safety Concerns: glycol decomposition can release hazardous byproducts, causing unsafe operating conditions and posing risks to both the operator and equipment.

Centralized Open-Loop (Cooling-Tower) Systems

Open-loop systems are vulnerable to contamination, impurities and mineral deposits, especially calcium. As temperature and pressure rise in the circulation systems, the solubility of these minerals decreases, forcing them out of the circulating water and causing them to solidify and form hard deposits, known as scale, on the internal piping of the circulation system, hoses and the mold itself.

Buildup of as little as 1/16 inch can be equivalent to 3-5 inches of steel in terms of heat-transfer resistance. This inefficiency can result in increased energy consumption and potential product defects.

Potential Solutions

- Separate water supply system for distilled water that can maintain pressure and supply the unit with enough water to fill the system, hoses and mold.

- Regular cleaning: scheduled cleaning of the system can prevent scale from reaching problematic levels. This is highly effective, but costly, in terms of downtime and labor availability.

- Adding heat exchangers to tower cooling systems: this isolates the tower loop from the process loop, enabling the process loop to be treated and filtered to a high level.

- Using “dry” cooling towers: these air-to-water heat exchangers provide a completely closed loop system, enabling the process loop to be treated and filtered to a high level.

- Antiscaling agents: for use with closed loop systems, there are chemical additives available that, when introduced to the water, prevent the formation of scale by inhibiting the precipitation of minerals.

Potential Consequences

- Reduced Efficiency: scale buildup constricts water flow, making the system work harder to achieve the same cooling effect, which increases energy costs, reduces equipment life and impacts product quality.

- Maintenance Costs: removing scale can be a tricky and arduous process, often requiring specialized equipment, chemicals and professionals. Regular maintenance to prevent scale buildup, or to remove existing scale, can significantly increase operational costs and downtime.

- Inhibited Heat Transfer: because scale acts as an insulating layer, even a minuscule amount can drastically reduce the efficiency of heat transfer, and a compromised heat transfer rate can lead to increased energy consumption and longer process times.

- Material property alteration: in processes like injection molding, precise temperature control is critical in ensuring that plastic achieves its desired and intended properties. Even slight deviations due to scale buildup can lead to products with compromised quality, strength, flexibility and finish.

- Equipment damage and reduced life span: over time, scale leads to corrosion, pitting and other forms of damage to equipment, which can result in frequent maintenance, potential system breakdowns and shortened equipment lifes pans.

High-Temperature System Components

Everything used with high-temperature injection molding needs to be rated for the temperatures and pressures required by these systems. Using products that do not meet these requirements can result in poor functionality, decreased efficiency and potential injuries to plant personnel. By investing in specialized high-temperature solutions, molders can ensure a safer and more efficient production process.

Standard high-temperature stainless steel manifolds should be able to withstand temperatures up to 400°F and pressures up to 250 psi, with higher temperature and pressure systems withstanding temperatures up to 450°F and pressures up to 680 psi. High-temperature oil manifolds, meanwhile, can withstand temperatures up to 600°F and pressures up to 250 psi.

Molders should avoid: aluminum manifolds because they can start to soften at their annealing temperature of 320°F; manifolds with soldered valves because the solder will melt under high temperatures; and square steel and stainless steel manifolds because they’re made from structural steel and have no pressure or temperature rating.

High-temperature hoses should feature smooth-bore PTFE construction with steel braids and hydraulically crimped fittings that can withstand temperatures up to 450°F and minimum pressures of 1000 psi. These can also satisfy high-temperature water and oil applications. Corrugated PTFE hoses are well suited for high-temperature water and oil applications requiring increased flexibility, especially for small lengths that need to be bent in tight spaces. These can be used for temperatures up to 450°F and pressures up to a minimum of 1000 psi. PTFE hoses with hydraulically crimped/swaged swivel JIC fittings enable coupling and hose connections to rotate and move freely, which prevents twisting, kinking and excessive bending. Corrugated stainless steel flexible metal hoses with steel braids and welded-on fittings can withstand temperatures up to 1000°F and pressures up to a minimum of 1,000 psi. Silicone insulation covers for the PTFE and stainless-steel hoses listed above are required to protect plant personnel and to reduce heat loss from the hose.

In terms of water fittings and valves, seek durable construction that can handle the high temperatures and pressures required for these specialized applications. Swivel JIC fittings and matching NPT adapters provide leak-free connections without sealant; female swivel fittings prevent hose twisting and kinking, extending the life of the hose. Quick-connect fittings can quickly and easily connect and disconnect coolant lines to molds and dies, but it should be noted these fittings are limited to operating temperatures of 360°F. Temperatures above this require specialized fittings which have limited availability.

Steel or stainless-steel pipe nipples for mold applications are sometimes required, and NPT by JIC adapters are readily available. Stainless steel 2- and 3-piece valves are required for high-temperature water. Molders should note that the pressure rating on 2-piece valves decreases above 400°F. For those temperature levels, specialized 3-piece valves with the correct pressure rating for the equipment must be used. For high-temperature oil, steel 3-piece valves with special seats and packing are required, and it should be noted that due to its very low viscosity at operating temperature, heat transfer oil requires specialized valves, fittings and assembly techniques to ensure it does not leak. Application of locking valve handles provides safety and prevention of accidental opening.

Other high-temperature products and components that should be considered include flowmeters for measuring the flow rates and temperatures of circulating media, as well as flow regulators for managing flow. Low-flow indicators are a good idea for use in critical injection mold cooling circuits, such as bubblers and baffles, where flow is restricted and effective cooling is essential.

In terms of consumables, heat-resistant mold releases, lubricants and purging compounds are required, as are high-temperature heat transfer fluids with proven formulations for operating at elevated temperatures.

About the Author: Mickey Blyskal is president of Plastixs, Shrewsbury, Massachusetts. Plastixs increases productivity and optimizes efficiency of new equipment and work cells by eliminating small production issues that can become big problems for plastics processors, equipment manufacturers and process companies. Blyskal started Plastixs in 2000 after spending more than 20 years working with engineers at molding companies to help them solve problems with equipment and components. Contact: 888-792-2223; mblyskal@plastixs.com; plastixs.com.

Related Content

Process Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreHot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreRead Next

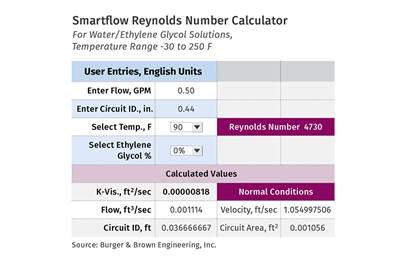

Cooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read MoreIs Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

Read More