Sandretto’s 3D Printer Highlights MilanPlast Show

A second injection press supplier throws its hat into the 3D ring. Meantime, several Italian suppliers’ growth plans target North America.

Held in early May outside of Milan, Italy, the 2015 MilanPlast show also hosted three satellite shows: Rubber 2015, 3D Plast (3D printing and related technologies), and StartPlasti (innovative startups). Together, their 1584 exhibitors attracted over 50,000 visitors from 115 countries. To ensure even bigger turnout in the future, the next MilanPlast will take place Sept. 26-30, 2017—a year in which it will not coincide with the NPE or K show.

Despite the latest MilanPlast’s proximity to NPE2015, BrazilPlast, and ChinaPlas, the show featured some new products and industry surprises. Some Italian suppliers are focusing their global expansion plans on North America. Most notable of these are injection machine builder Sandretto S.p.a.; Termostampi, a maker of precision molds for thermoforming; Bausano & Figli S.p.a. manufacturer of a wide range of single- and twin- screw extruders; and Comac s.r.l., producer of co-rotating twin-screw extruders and complete compounding lines for masterbatch production.

3D PRINTERS FROM SANDRETTO

The biggest news from Sandretto S.p.a. wasn’t about injection molding machines at all. Instead, the company unveiled a range of heavy-duty, FDM-type industrial 3D printers. This makes Sandretto the second injection press manufacturer to enter the additive manufacturing arena, after Arburg, which launched its Freeformer at K 2013 and debuted it in North America at NPE2015 in March. Sandretto says its plans in additive manufacturing include investigating technologies ranging from “hot-wire” deposition to polymerization of filled resins to sintering metal powders.

The newly launched Delta machines were initially built to use 1.73-mm filament and have been tested with PLA, ABS, TPU, HIPS, SEBS, PET, and PETG. “We can run all types of resin filaments used in FDM and laser sintering processes, as well as SLA photopolymer powders,” explains Roberto Moretti, COO of Sandretto’s new Additive Manufacturing Div. Delta can even use filled compounds such as PLA with 20% bronze powder. Moretti also said that by year’s end there would be a wider range of materials, including the option of using granulated plastics, as well as polycarbonate and PTFE.

“These machines allow you to change parameters such as temperature and pressure, adapted to the material to be used. There is also software that will allow them to work automatically,” states Moretti. He notes that the largest of the three models has a third vertical axis for isotropic properties so that even complex parts can be produced with the same quality as those that are injection molded.

The company is setting up a dedicated laboratory, Sandretto Skunk Works Lab, to handle the development process. Moretti says the firm is ready to produce 1000 machines/week. For the North American market, Sandretto will set up a direct branch for additive manufacturing by end of this year, to be followed by assigning distributors, says CEO Fausto Ventriglia.

BARREL HEATING BY INDUCTION

Another interesting new technology was also unveiled by Sandretto. It’s newly enhanced Series Ten injection press line features barrel heating by electromagnetic induction, which is said to reduce heating time by 40%. The induction heating system consists of a power supply and a coil. Converting electricity into heat occurs with no contact between the coil and barrel. Key advantages include about 35% faster heat-up, an average of 50% less variability in part weight, and 96% efficiency vs. 70% for resistive heaters.

Protected by two patents, the Series Ten line is available in clamping forces from 30 to 500 tons. The series has a new injection unit and a more rigid base structure, as well as greater tiebar spacing. Hydraulics powered by brushless, variable-speed motors reportedly produce energy savings of 25% over traditional systems. These units are also equipped with the new SEF 3000 electronic control system, said to be intuitive and easy to use. Its graphical interface supports easy navigation and learning, reducing operator errors.

NEW COMPOUNDING EQUIPMENT

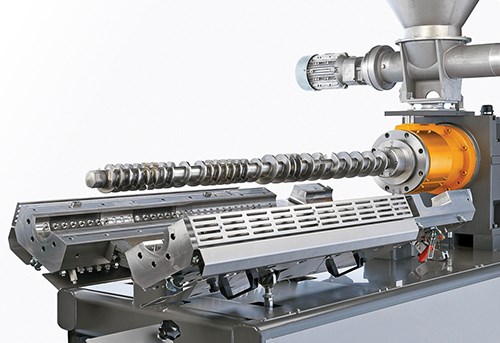

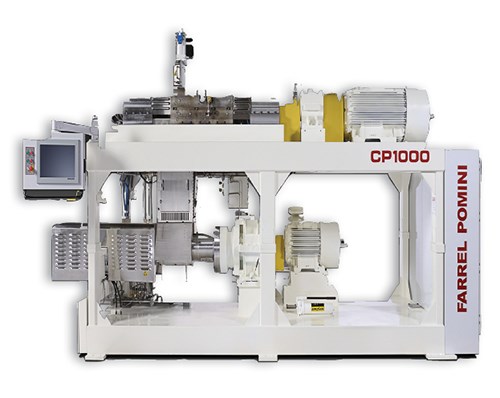

Farrell Pomini, Ansonia, Conn., displayed the latest and largest addition to its CP Series II of compact processors. Model CP4000 has a 60% greater production capacity (5512 to 11,023 lb/hr) than the company’s next largest size (CP2500) and has unitized ancillary equipment.

The CP4000 is a direct scale-up of the company’s small-to-mid-sized CP550, now available for lab testing both in the U.S. and UK. Both are designed for top-quality dispersion of highly filled, highly pigmented materials as well as highly abrasive compounds. A hybrid of Farrel’s CP 2500 and 9UM, the CP4000 is equipped with an integrated continuous mixer and 12-in. extruder for applications such as masterbatches, compounds with high levels of fillers, and temperature-sensitive materials.

Switzerland’s Buss (U.S. office in Carol Stream, Ill.;) showcased the latest addition to its quantec G3 family of high-performance kneaders, first launched at K 2013. These are designed for rigid and flexible PVC compounding at up to 13,227 lb/hr. Like the other units, the new quantec 46 G3 reportedly offers outstanding time and cost efficiency. With throughputs up to 1100 lb/hr for filled PVC, this smallest version of the series is said to offer optimal flexibility and short changeover times for frequent formulation changes.

Said to be very cost-effective for small to medium production runs, the machine is delivered as a turnkey compounding line, with all components from feed intake to control cabinet and pelletizer mounted directly on the base frame. The 46 G3 is also very compact: Its footprint is only about 30 ft².

TESTING & ADDITIVES NEWS

Two suppliers of testing instruments discussed new products at the Milan show. MTS, Eden Prairie, Minn., introduced its first plastics pendulum impact tester. Exceed Model E21 can perform Charpy, Izod, and tensile impact tests. It comes with a controller that is used to set test parameters and calculate, record, store, and print test data.

Instron, Norwood, Mass., is planning to launch this September a new generation of HDT testers. The HV3N thermo-mechanical tester has a more compact footprint, features touchscreen operation, faster testing, and faster cooling after testing. It has enhanced safety features and boasts energy conservation.

The Tosaf Group of Israel (U.S. office in Blauvelt, N.Y.), a manufacturer of additives, masterbatches, and compounds, is reportedly close to making its manufacturing entry into North America. Tosaf expects to start up its plant in Bessemer City, N.C., in the first quarter of 2016, where it will make a broad range of additives for packaging, agricultural films, and construction uses, ranging from antifog, antislip, and antistat to antioxidants, UV stabilizers, and flame retardants, as well as a range of color and additive masterbatches.

Related Content

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreAdditive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

Read MoreAdditive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreDuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More