Several Thermoplastic 'Firsts' Among 2018 SPE Automotive Awards

With the addition of an Additive Manufacturing slot, all nine categories exemplify innovation and transferability in the use of plastics.

Spanning nine categories, including one newly added for Additive Manufacturing, the Society of Plastics Engineers Automotive Division’s 2018 Blue Ribbon Automotive Innovation Awards (which this editor helped judge) represented a number of “firsts” in either metal replacement or replacement of earlier plastics solutions with better options. In this 48th annual competition, the oldest and largest competition of its kind globally, thermoplastics and/or thermoplastic composites ruled. Here’s a look at the winners, starting with the grand winner award—also the winner of the Powertrain category.

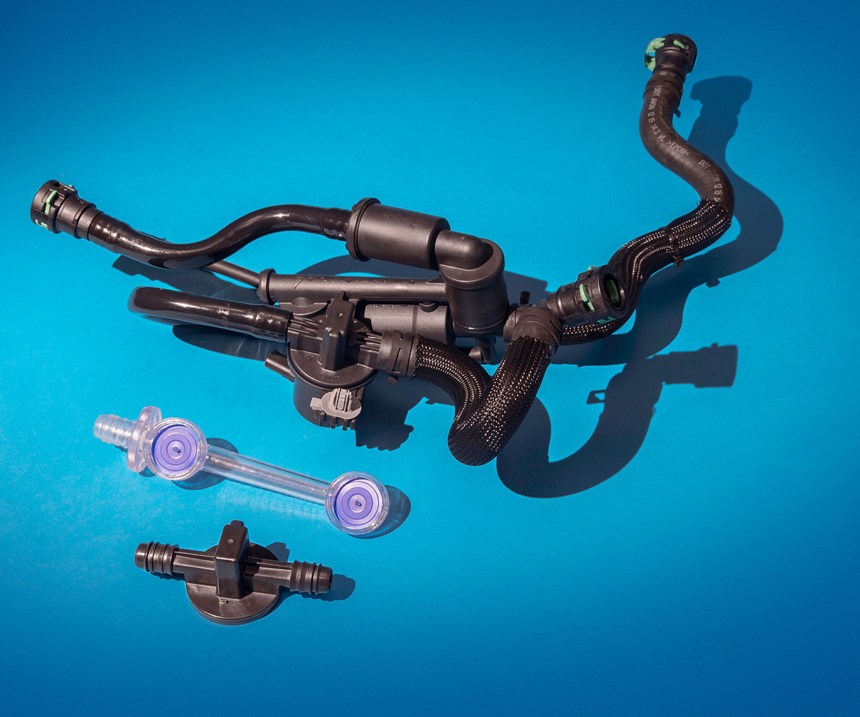

POWERTRAIN: VACUUM GENERATION SYSTEM FOR BRAKE ASSIST

The open/close valve-actuation system made its debut in the 2017 Ford F-150 pickup, and was designed and supplied by Tier One supplier Dayco Products and molded by MacLean-Fogg’s Engineered Plastics unit. The system utilizes two complimentary resin systems from DuPont Automotive—Delrin 73M30 acetal with PTFE, and Minion 520MP mineral-filled nylon 6—which together prevent “stick-slip” and result in no measurable wear after 2.5 million hot/cold test cycles. A 40% weight savings and a 25% cost savings over current pump systems was achieved.

This application is transferrable to other Ford platforms and is being considered by other car companies.

ADDITIVE MANUFACTURING: WINDOW ALIGNMENT FIXTURE

This fixture appears in the 2017 Ford Mustang convertible and was produced by Stratasys using its Fused Deposition Modeling (FDM) system and nylon 12 with 35% short carbon fiber. The fixture integrates pneumatic control, eyelets for a stowage rack, trigger-switch housing, ergonomic handles, gauge-protector deflector and pneumatic-tubing retainers and switch mounts. This unit is 30% lighter and cheaper to produce than a traditional welded fixture. It is also much faster to manufacture—taking only 50 hr to build the integrated fixture with handles and mounting brackets. Moreover, ergonomics reportedly were improved significantly. The plastic fixture allows for easier handling and avoided the requirement for a lift assist.

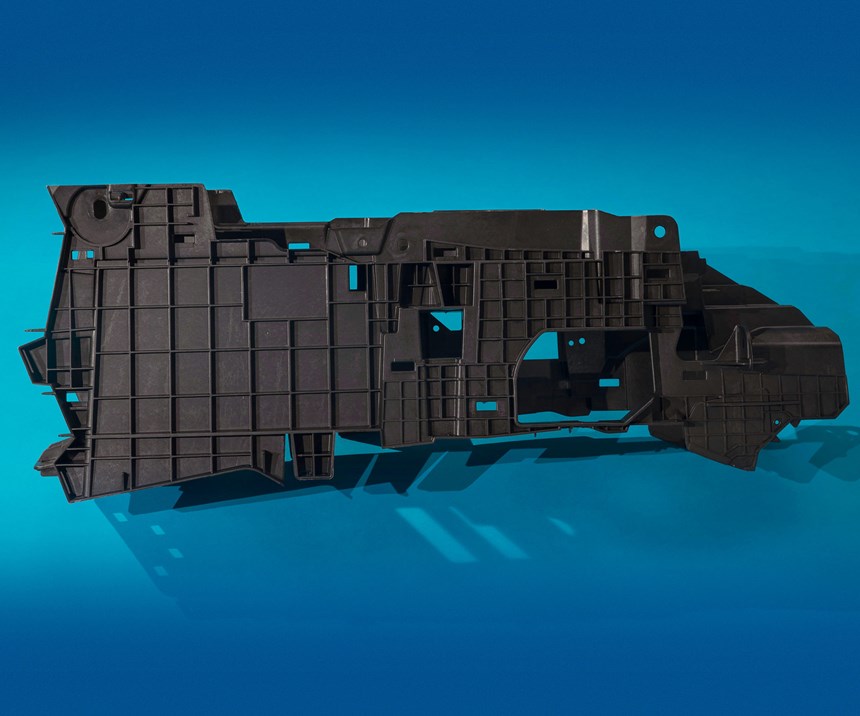

BODY EXTERIOR: THERMOPLASTIC LIFTGATE

This liftgate appears in the 2019 Fiat Chrysler’s Jeep Cherokee SUV, and was molded by Magna International’s Magna Exteriors business. It’s injection molded from Trinseo’s DLGF 9411, a 40% long-glass PP with good flow properties, and Lyondell Basell’s Hifax TYC, a very high-flow TPO containing 30% glass. The integrated tethering attachments are molded in glass-filled nylon. Replacing a steel liftgate with a thermoplastic design enabled a 28% weight reduction and a 50% savings in tooling and capital investment through part integration and manufacturing efficiency.

An industry-first use of conformal infrared welding behind the MIC (molded-in-color) grain class A surface increased structural and dimensional performance and enabled quicker processing. Bonded brackets enabled novel tethering attachments without fasteners, improved metal reinforcement efficiency, and maintained styling surface wrap in D pillars without sacrificing DLO. All this was accomplished within an 18-month window.

BODY INTERIOR: INTEGRATED MODULAR PELVIC BOLSTER

This application appears on the 2018 Ford Lincoln Navigator SUV and is molded by Faurecia Interior Systems from LyondellBasell’s Profax SX702, a high-flow, high-impact PP copolymer. The unit combines two unique side-impact bolster designs. Integrating them into the map packet resulted in tooling cost savings estimated at $100,000. There was an additional $100,000 indirect savings in testing time and $8 per vehicle cost avoidance vs. using add-on bolsters. An approximate 10% weight savings was achieved.

CHASSIS/HARDWARE: HIGH-STRENGTH, SELF-TAPPING COMPOSITE NUT

This appears on the 2016 Fiat Crysler Pacifica minivan and is molded by ITW Deltar Fasteners from Asahi Kasei Plastics’ Leona 90G55, a 55% glass-filled nylon 66. This composite nut has self-healing properties, enabling it to maintain sufficient torque and clamp load even after it has been stripped, unlike the metal nut that it replaces.

Total mass savings is 8 g per location x 121 locations, for a total vehicle mass savings of 2.1 lb for this vehicle. Estimated cost savings per vehicle is $3.25. The composite nut can be translated across all OEMs and in many additional applications.

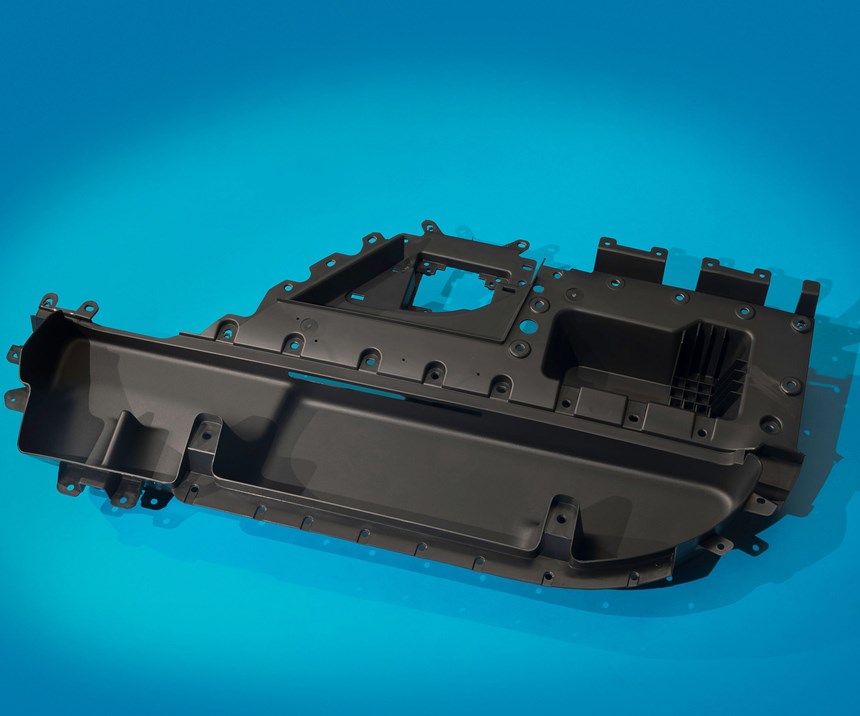

ENVIRONMENTAL: SUSTAINABLE HYBRID COMPOSITES

This center console carrier appears in the 2018 Ford Lincoln Continental luxury sedan and is an industry-first application of composites combining cellulose fiber from trees with long-glass fiber (LGF) in PP to replace 35% short-glass/mineral-filled PP. It used International Paper’s Thrive cellulose composite made with Celanese’s Celstran PP+HC, containing LGF and continuous glass fiber with PP and recycled PP. Melt compounding was followed by injection molding by Tier One Summit Polymers. A 24% weight savings and a 13% cost savings were realized. A total of $2 million cost savings resulted from reducing weight and reducing cycle times by 20& to 40%. This is said to be the largest single automotive part thus far that is made with sustainable plant-based composite materials.

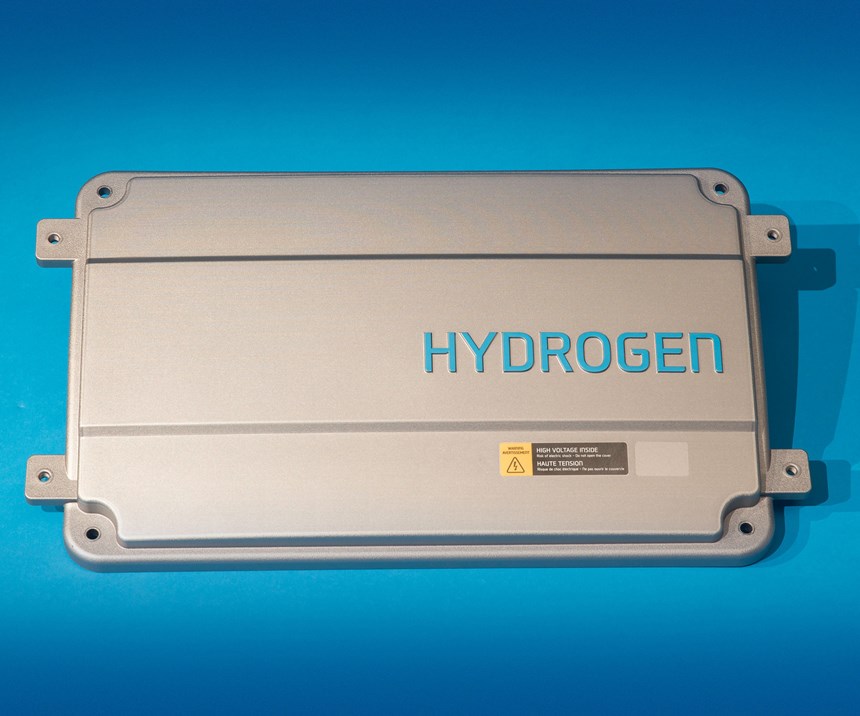

MATERIALS: EMI SHIELDING COMPOUNDS FOR HIGH-VOLTAGE COVER

This application debuts on the 2019 Hyundai Nexo SUV. It is made of a new conductive plastic compound from Hanwha Compound, developed specifically for EMI shielding of high-voltage junction-box upper covers. Injection molded by Yura Corp., it is made of Hanwha Compound ESM-204B nylon 6/PPO compound with hybrid conductive carbon filler (carbon fiber, nano-carbon fiber/carbon nanotubes, and carbon black). The material, which contains no metal powder or metal-coated fiber, replaces conventional die-cast aluminum covers for reduced weight and manufacturing costs. Weight savings are estimated at 30% (0.3 kg) and cost savings are estimated at 70% ($50 per vehicle.)

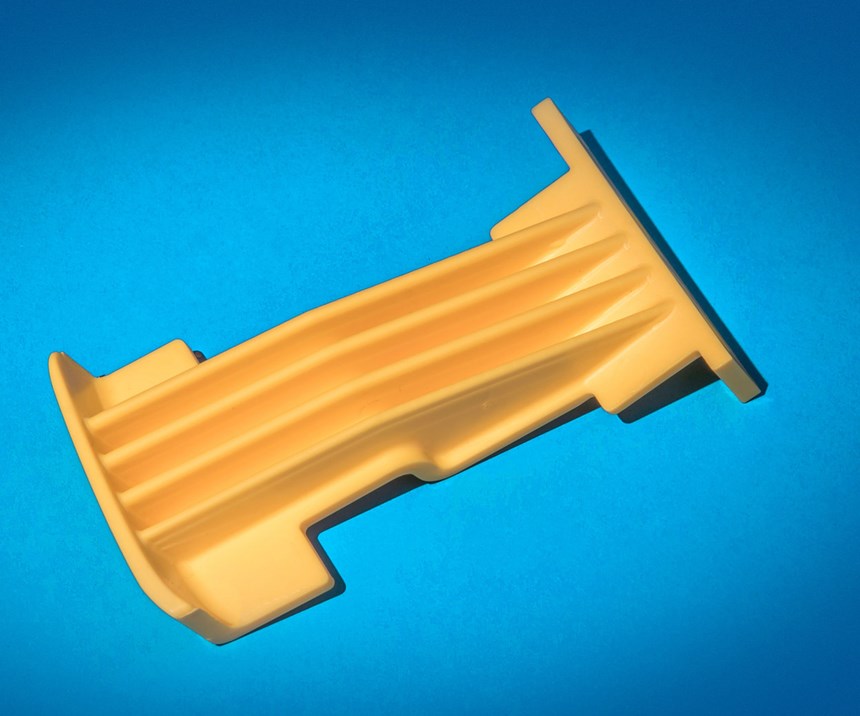

PROCESS/ASSEMBLY/ENABLING TECHNOLOGIES: INTEGRATED TIRE CARRIER, REAR CAMERA & BRAKE LIGHT

This appears on the 2018 Fiat Chrysler Jeep Wrangler SUV. Its hybrid composite technology utilizes Legerra Technologies’ injection molded magnesium (thixomolding) and TMD-Grammer AG’s overmolding with DuPont’s Zytel ST 801 AW, an unreinforced, super-tough nylon 66. It is said to offer higher structural strength with reduced weight and improved impact and corrosion resistance.

Weight savings are 60% vs. metal stamping and 20% vs. die casting. Cost savings are 20% with an improved load rating from 85 to 115 lb. The new design also eliminates the need for a steel bracket.

SAFETY: INTERLOCKING MECHANISM DESIGN FOR SIDE IMPACT

This debuts in the 2019 Ford Transit Connect van. It was designed and molded by Furecia Interior Systems and Thermolympic SL using Trinseo’s Magnum 3325MT, a medium-heat ABS with low gloss and high flow. This interlocking mechanism improves door-trim performance during side impacts by preventing fracture or separation of components that could leave sharp edges.

This design provides strong attachments, force absorption, and high impact resistance between two components during side impact. It replaces the need for metal brackets, saving 3.70 kg per vehicle. Cost avoidance of $30.60 per vehicle and tooling-cost savings of $9.88 million were achieved, along with 3.7 kg vehicle weight saving.

Related Content

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More