Solving Common Problems in Underwater Pelletizing

Pellet quality and consistency are critical to any compounding operation. But in underwater pelletizing, a variety of issues can stand in the way. Here’s how to fix them.

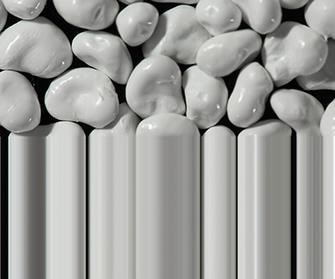

Compounders face many challenges today. Maintaining consistent product quality is critical to success. One of the most common issues with underwater pelletizing is pellet inconsistency. Pellet inconsistency can be caused by improper die selection or sizing or by output fluctuations.

In this article, we will examine several issues that contribute to pellet inconsistency and suggest ways to solve them.

IMPROPER DIE SIZING

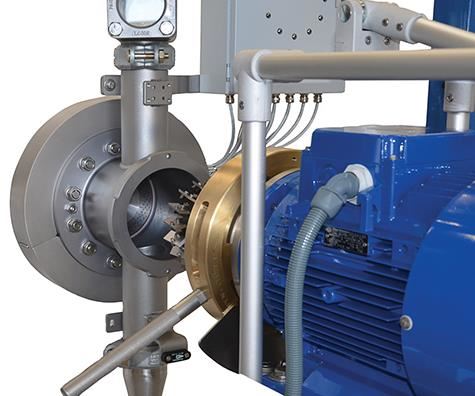

In most underwater pelletizing applications, improperly sizing the die can lead to poor polymer flow uniformity across the die-hole cross-section and actual solidification of polymer in the die hole (sometimes referred to as freeze-off). To prevent die freeze, a minimum polymer velocity through the extrusion hole and the correct die temperature must be maintained.

In most cases, 2.5 to 3 ft/sec velocity through the die hole is recommended to to prevent the extrudate from solidifying in the hole. To maintain correct velocity per hole, you must have the correct number of holes in the die plate for the desired production rate.

Let’s look at sizing a die using a hole diameter of 0.125 in. (3.2 mm). In order to achieve the recommended velocity you need 50 to 60 lb/hr per die hole (V=0.0002122/R2 x rate per hole in lb/hr). Keep in mind that this is based on a material with specific gravity of 1. In many instances where there is a significant amount of filler or pigments, the material will have a much higher specific gravity. This needs to be taken into consideration when sizing the die.

For example, if a material has a specific gravity of 1.8 you need to run 1.8 times the 50 to 60 lb/hr per die hole. This can be very deceiving. You might think it is necessary to add more holes to the die to reduce the pressure drop across it, when in reality, fewer holes are needed so that all stay “open” while running. There is a calculation to determine if all die holes are open while running. It is as follows:

X = R × 7.6 /(W × S × N) where:

X = Number of open holes

R = Rate in lb/hr

W = Weight in grams per pellet

S = Speed of the pelletizer in RPM

N = Number of blades on the cutter hub

Generally speaking, the velocity of polymer, in addition to the heat it provides at the die plate, must be managed properly to facilitate a cleanly cut pellet. Without this control or understanding, few process settings or engineered devices can provide a full solution to certain process problems causing pellet inconsistency.

IMPROPER DIE TEMPERATURE

This can also contribute to die freeze. In most cases the die temperature should be 25° F higher than the melt temperature of the polymer. This may vary a bit from product to product, but it is a good starting point. The temperature of the die can also be affected by insulation. Most dies are insulated in some form. This is necessary to isolate all but the cutting face from contact with the process water to prevent the die from losing heat.

This insulation is usually sealed with a high-temperature, room-temperature-vulcanizing (RTV) silicone, and you need to be aware of the temperature ratings. Sealant degrades over time and at elevated temperatures, which allows water to seep into the insulation and bring the die temperature down. For example, suppose the die temperature drops significantly from setpoint at startup and the control system is calling for heat, but the die struggles or never comes back up to the original die heat setpoint. This is a very good indication that the die plate insulation has degraded, is missing, or is improperly installed.

Check the amount of power the die is using. Many control systems are equipped with an ammeter on each die heat zone. Calculate the amp draw required for each heat zone then compare with the actual reading. If the reading is less than optimum, one or more heaters have likely failed.

DIE-HOLE BLOCKAGE

Inconsistent pellets can be caused by physical blockage of the die holes from contaminants in the material or from mineral fillers not dispersed well in the matrix. In most cases a screen changer or some type of filtration prior to the die is desirable. On smaller systems this type of blockage can be removed from the die hole using a special hand-cleaning tool. On larger systems the die is usually removed for cleaning. It is also advisable to reduce temperature profiles, including the die heat zone, during prolonged periods of idle time.

Up to this point we have talked about cause and effect on the underwater pelletizer itself, but there can be several factors in the process that may lead to inconsistent pellet sizes. Feedstock bridging in the hopper can reduce the flow of material into the extruder. Depending on the product being processed, this can result in inconsistent pellets or may cause die freeze.

Improper extruder temperature settings can cause surging in the extruder, causing pellets sizes to vary. This can also lead to a melt temperature that is too high, which may not necessarily cause inconsistent pellet sizes, but can cause pellet deformity.

FINES AND TAILS ON THE PELLETS

This problem can be attributed to a number of factors; however, it is typically caused by die and/or blade wear. If the die-plate cutting face becomes grooved, it is not possible for even a new and sharp blade to cut the polymer cleanly. At the point of the cut, a small amount of the material is pulled through that groove, resulting in a tail on the pellet. The same thing can be said of a blade that is grooved and operating on a new die face. This highlights the importance of choosing the correct—and compatible—materials of construction for the die face and blades. Using a blade that is too hard may give you a little longer blade life in the short term but can accelerate wear on the die face.

Other possible causes for tails are excessive melt temperature, die alignment out of tolerance, mechanical wear issues on pelletizer bearings resulting in excessive shaft run-out, or process water that is too hot.

It must also be emphasized that without maintaining proper polymer velocity through the die-plate extrusion holes, an exaggerated flow gradient exists within the die hole, causing a sleeving effect. This creates an undesirable polymer shoulder against which the blade will struggle for a clean cut.

As the pellet goes through a centrifugal dryer, the tail breaks off, resulting in fines. This can cause problems in material-handling systems as well high residual moisture on the pellets. Fines can stick to the dryer screens, reducing the open area and air flow through the screens.

Fines are not the only possible cause for higher than desired residual moisture content on the finished pellet. Other causes include melt fracture (or “shark skinning”), a pellet that is porous due to high loadings of filler or fibrous material, irregular pellet shape, as well as operating or environmental parameters.

Melt fracture produces a very rough surface on the pellets, providing numerous places to trap water as the pellet travels through the centrifugal dryer. This rough surface presents itself on the side wall of the pellet and generally not on the cut ends. One way to minimize melt fracture is to cut the pellet a little thinner, thereby reducing the sidewall area. Keep in mind this does increase the total surface area. Another way to minimize melt fracture is to reduce the velocity through the die holes, in addition to polishing or extrude-honing the dies.

High levels of mineral filler can produce a porous pellet that can be very difficult to dry. This porosity allows water into the voids, which can be very difficult to remove by centrifugal action alone. Fiber fillers such as glass or wood act like a wick to draw moisture into the pellet, making it almost impossible to dry mechanically, so post-drying may be required.

Since centrifugal dryers operate on three basic principles—residual heat in the pellet, centrifugal action, and countercurrent ambient air flow—proper operating parameters must be established. For example, if the process-water temperature is too low, the resulting pellet temperature will be too low to flash off sufficient surface moisture. On the other hand, if the water temperature is too high, tails may be generated. Countercurrent air flow through the dryer is very important to reduce surface moisture levels. It should be checked and adjusted to the manufacture’s specifications.

Environmental conditions can play a significant role in the reduction of pellet surface moisture. For a process line located in a very humid area and processing a melt-fractured or porous pellets, one would expect very low pellet-moisture levels will be difficult to obtain. Also, if running a product that is very sticky and requires very cold water, and the pellet is exiting the dryer at a temperature below the current dewpoint, then even though the pellet may be dry as it exits the dryer, condensate will form, resulting in higher moisture content when it is packaged.

These are some of the common issues that are faced by operators of underwater pelletizing systems. Proper understanding of cause and effect can in most cases eliminate these problems. If you find yourself faced with some of these problems, contact your underwater pelletizer manufacturer to help improve your process.

Related Content

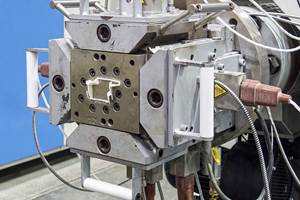

Auto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

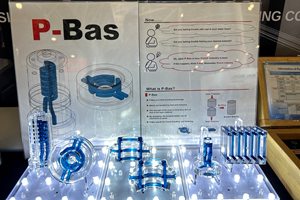

Read MoreBonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreNovel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.

Read MoreIs Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More