Super-Compact Auxiliary Injection And Intrusion Units

Unusually compact secondary injectors outfit standard presses for multicomponent and sandwich molding.

Vector Injection is still a new name to most U.S. molders, though the firm was started five years ago in Acton, Ont., by a veteran of another Ontario firm, Mold Hotrunner Solutions (MHS), which builds hot runners and micromolding systems. “Melt delivery is the core of our business,” says Vector Injection president Evan Goodwin. “We use a combination of injection, extrusion, automation and robot integration to develop custom part manufacturing solutions.”

He describes his company’s business as comprising three main activities. The largest, in terms of revenue, is building custom injection molding machines, totally from scratch, and embodying some rather unusual designs. One system, for example, was built to mold auto exterior components. It mounts automation on a press and a robot arm to mold with multiple injection units on a single mold, applying 10 tons of force per injection location.

A second business line is working with moldmakers to incorporate servo motions for slides, cores, and other components. “We fill a gap between moldmakers and automation specialists,” Goodwin explains.

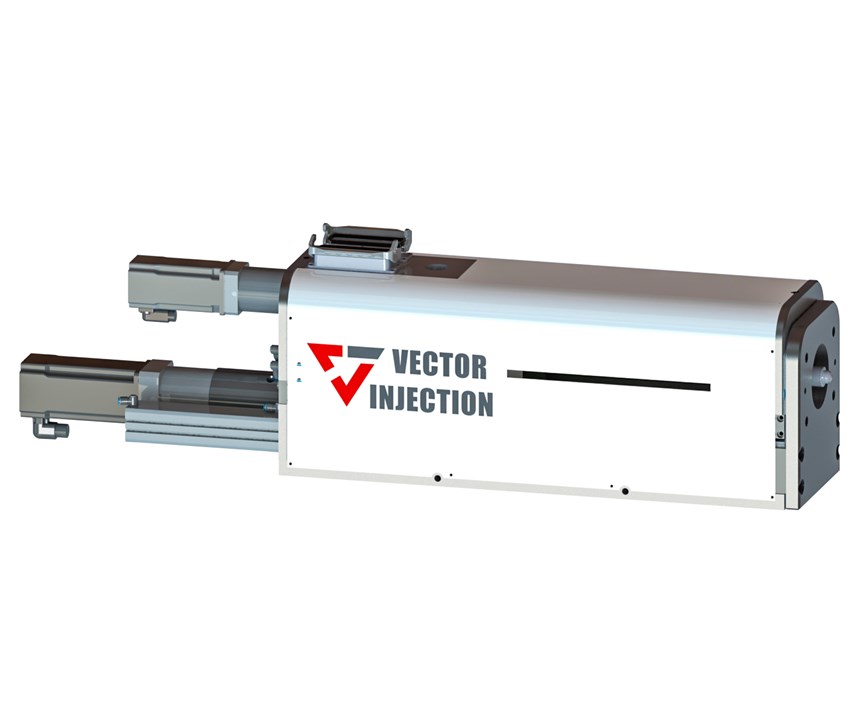

The business line of interest to the widest molding audience is Vector Injection’s range of secondary injection units, which add multicomponent capability to any conventional press. Goodwin says these are 30% shorter and 50% lighter and have 30% smaller footprint than his closest competitor, enabling these mold-mounted units to fit within the molding machine guarding. No additional support or stand is needed. For example, a small unit is less than 6 in. wide and mid-sized unit is only 6.5 in. wide, “So it can be mounted very close to the platen without adding extra height to the clamp plate,” Goodwin notes. When mounted on a mold parallel to the parting line, only 3 in. of mold height is required to reach the melt-path inlet. The unit is designed so the screw can retract fully into the injector housing, making it easy to mount the unit on a mold that is already hung in the press. The fully retracted screw is also said to allow for easy mechanical screw cleaning, making for very efficient color changes.

The X-Caliber units are electric servo driven and can be mounted vertically or horizontally on the mold, either parallel or perpendicular to the parting line. They come in three sizes, each with a choice of seven sizes of reciprocating screw, for shots from 1 g to 300 g (0.65 lb). Maximum injection rates are from 20 to 280 cc/sec. Pressure capabilities are up to 40,000 psi. Standard features include a mechanical shutoff nozzle, 8-in. nozzle pull-back, and controller with 15-in. touchscreen and eight-zone valve-gate control. Goodwin points out that the shutoff nozzle eliminates the variability of check rings and allows overlap between plasticating and mold opening for faster cycles.

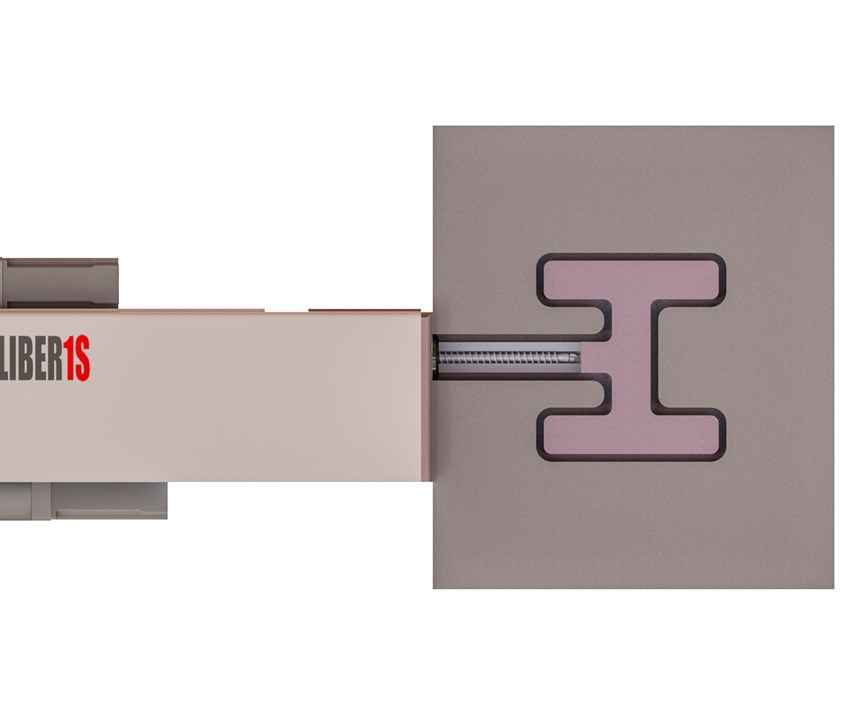

Vector Injection (vectorinjection.com) has a patent pending on a “split barrel” design in which the front two-thirds of the barrel (typically 25:1 L/D) is permanently fixed to the hot-runner manifold near the centerline of the mold. This reduction in flow length reduces the pressure drop, shear and residence time the material experiences through the hot-runner system, Goodwin explains.

SINGLE- OR TWO-STAGE INJECTION

X-Caliber units come in reciprocating single-screw and two-stage versions. The two-stage units have a stationary extruder to plasticate the melt and a second, reciprocating screw for injection. During plastication, a PID loop controls the injection screw position to maintain consistent backpressure. A mechanical shutoff valve blocks flow between the extrusion and injection barrels. Goodwin notes that he uses an injection screw instead of a simple plunger to counteract the inevitable small amount of leakage back over the front of the injector. Further, this arrangement retains the first-in/first-out advantage of a reciprocating screw, which is lost with a conventional plunger.

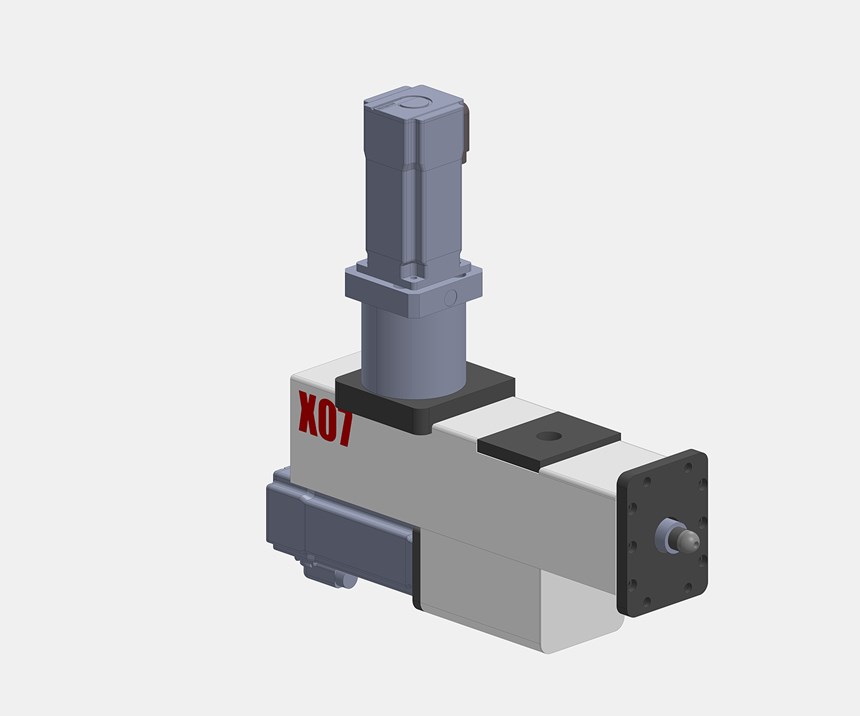

Vector Injection also offers the X-07 micro-injection unit, a two-stage model that uses a 12- or 14-mm plasticating screw, which can accommodate standard-size pellets, and an injection screw of 0.04 to 0.08 mm diam. Shot sizes can be as small as 0.05 to 0.5 g. Maximum shot size is 6 cc and maximum injection speed is 25 cc/sec. Pressure capability is up to 35,000 psi.

INTRUSION MOLDING UNITS

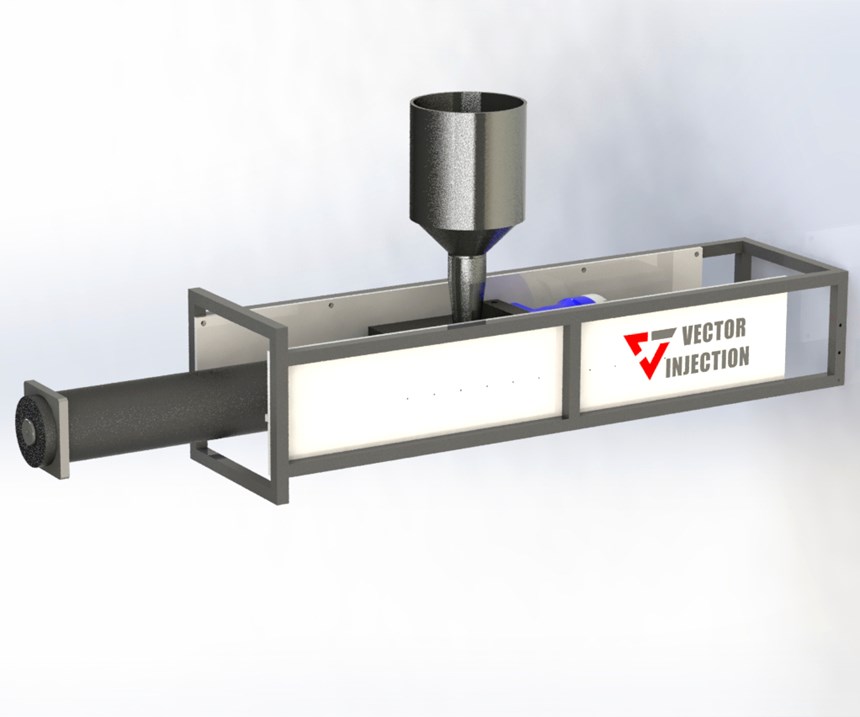

For special cases requiring larger shot capacities than a standard machine can deliver, Vector Injection also offers add-on intrusion units—mold-mounted, servo-driven extruders. One, called the Intruder, is a very lightweight, 22-mm, 20:1 unit with pressure control that can convert any injection machine for co-injection or sandwich molding with a thick core between two skins.

A much larger unit is called the BFE. Still developmental, this unit has a large screw of 10:1 L/D; it can deliver a 35-oz shot but is less than 10 ft long. A typical injection unit of similar capacity would be more than twice as long. The BFE was designed to increase the injection capacity of medium-to-large injection machine and to facilitate skin-core co-injection of big parts, perhaps with recycled resin in the core. Like the smaller unit, it is mounted onto the side of the mold.

Related Content

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More