Switching Hydraulic Oil Saves Energy & Machine Downtime

Test at leading molder shows a high-viscosity, zinc-free oil improves pump efficiency and runs longer, cleaner, and quieter.

Injection molders and other plastics processors may think of hydraulic oil (when they think of it at all) as a necessary evil rather than a resource for improving their manufacturing efficiency. Perhaps they should think again. Experience at one prominent molder indicates that a premium shear-stable, high-viscosity index (VI) hydraulic oil can be well worth the additional cost in energy savings and reduced downtime for oil changes and valve maintenance. And it can make machines run quieter, to boot.

A NEW WAY TO SAVE ENERGY

Mobil DTE 10 Excel is a family of premium hydraulic oils that has been used for over 10 years in high-load applications such as large foundry presses and off-highway vehicles. However, 2017 marked its debut as a certified source of energy savings, having been tested at eight U.S. injection molders and one metalworking machine shop).

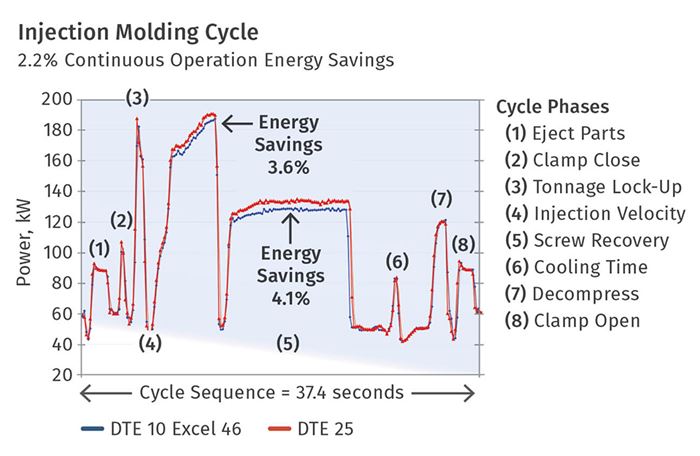

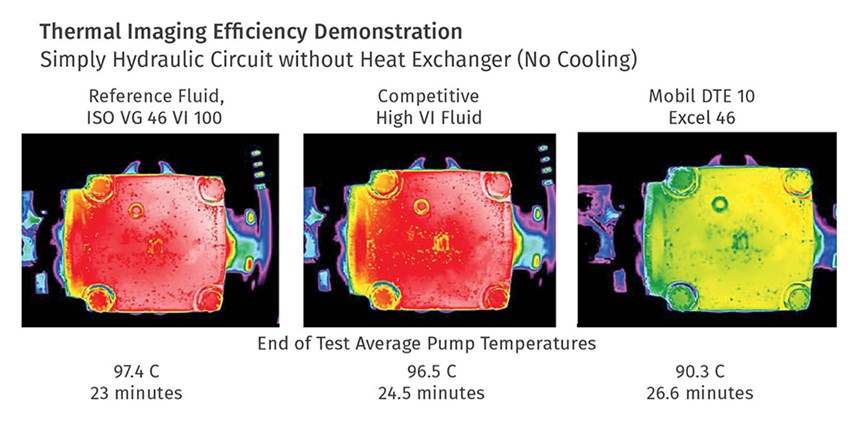

According to Michelle Ruiz, field engineer for ExxonMobil Fuels & Lubricants, Spring, Tex., Mobil DTE 10 Excel is a zinc-free, highly refined mineral oil with a low traction coefficient and shear-stable, high VI that allows it to run cooler and more efficiently than standard hydraulic fluids. It is formulated to provide both reduced internal friction among the oil molecules and less variation in viscosity with temperature. In other words, it flows easier at lower temperatures, such as at machine startup, and “thins out” less at elevated temperatures, as when the oil warms up during continued press operation. She adds, “It is designed for a balance of mechanical efficiency—maximum pump rotations from energy input—and volumetric efficiency—maximum fluid transferred from energy input—which tend to counteract each other but can be balanced by reducing internal leakage. That translates into up to 6% greater pump efficiency, in controlled bench testing with a typical vane pump, than with ExxonMobil’s Mobil DTE 20 series oils.

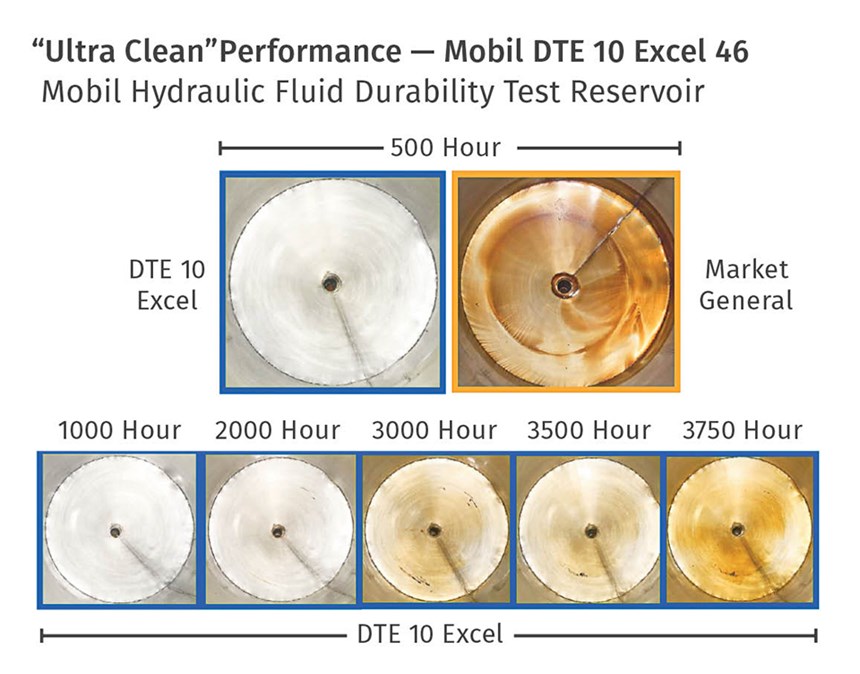

Ruiz notes that Mobil DTE 10 Excel is also designed for long oil- and filter-change intervals, to keep systems running clean up to three times longer than conventional mineral-based oils.

TESTING AT MOLDERS

EVCO Plastics, DeForest, Wis., is a $150 million custom injection molder with over 1200 employees and 170 machines at nine plants in the U.S., Mexico, and China. It has pursued energy-saving projects such as more efficient LED lighting and a new air-handling system. The company has even considered solar panels. As explained by Bernie Degenhardt, automation and maintenance manager, discussions with EVCO president Dale Evans raised the question of why the firm couldn't look for savings at the most basic level of its operations, such as the hydraulic oil that powers most of its machines.

Engineers from EVCO and ExxonMobil worked together on controlled testing at EVCO’s Innovation Center at DeForest. “It was an ideal situation for controlled testing,” says Ruiz. “The molding test area is environmentally controlled and, most important, the machine’s power factor is isolated from other electrical equipment.”

The week-long test involved a 1996 Van Dorn injection press with a 300-ton toggle clamp. Polypropylene parts were molded on a 1-min cycle. The test demonstrated a 3.2% reduction in electricity demand on that machine. Also participating in the test were engineers from Focus on Energy, a program of Wisconsin electrical utilities that provides businesses in the state with information, resources, and financial incentives to implement energy-saving projects. EVCO has worked with Focus on Energy on previous projects such as its upgrades of lighting and air-handling systems. As a result of the test at EVCO, Mobil DTE 10 Excel is believed to be the first hydraulic oil to qualify as an energy-efficient technology under a statewide incentive program.

Questions about injection molding? Visit the Injection Molding Zone.

Another result of the test is that EVCO plans to use the more efficient hydraulic oil in additional machines. “We’re taking it in stages,” says Degenhardt, starting with six new tiebarless, servo-hydraulic Engel victory presses of 55 to 130 tons that will be going into a newly expanded medical molding plant in DeForest. Degenhardt is also eager to test the oil in a larger press with a more complex hydraulic system, where the energy savings could be greater. “I really want to get it into the 2000-ton press, which wasn't available for the earlier test.” If that trial is also successful, Degenhardt foresees a gradual program of introducing Mobil DTE 10 Excel in more and more of EVCO’s machines, starting with the largest tonnage models.

QUICK PAYBACK

One obvious reason why plastics molders haven’t adopted this more efficient hydraulic oil sooner is that it costs up to twice as much as standard oils. Part of that additional cost can be defrayed by programs such as Wisconsin’s Focus on Energy, which, in Ruiz’s experience, has paid 26% to 27% of the incremental cost for energy-saving technologies.

Three times longer between oil changes and greatly reduced varnish deposits on valves help pay for a premium hydraulic fluid.

According to Ruiz, prior experience at another injection molder and a metalworking plant showed payback in 18 to 24 months from energy savings alone. Both Ruiz and Degenhardt agree that molders have to look at much more than energy savings to justify switching to a premium hydraulic oil. “Varnish buildup on valves is a big problem,” notes Degenhardt. Not only does that require downtime to remove and clean or replace dirty valves, but a much more concerning factor is that while varnish is accumulating on the valves, the machine’s performance is gradually drifting, affecting quality and cycle time.

Degenhardt also credits the substantial advantage of up to three times longer periods between oil and filter changes promised by Mobil DTE 10 Excel. That again saves costs of downtime and disposal of waste oil. Ruiz says typical hydraulic oils used in molding machines contain zinc as an anti-wear additive.

But zinc is responsible for sludge and varnish accumulation as the oil ages in use. Mobil DTE 10 Excel is zinc-free. And there’s one other, quite unexpected, benefit from changing to the new oil: “When I entered the lab, I couldn't hear the machine. I had to ask, ‘Is this thing running?’ It was so quiet.” Ruiz explains that Mobil DTE 10 Excel contains air-release additives that prevent micro-cavitation, which accounts for noise in operating hydraulic systems.

Trend to More Efficient Hydraulic Oils

ExxonMobil’s Ruiz says there has been an industry-wide trend toward improving the energy efficiency of hydraulic oils. Other evidence of that trend that has appeared in Plastics Technology includes these articles:

“New Hydraulic Fluid Trims Energy Consumption,” a case history of custom injection molder Niigon Technologies, which saved 13.6% in energy use with Tellus EE, a new synthetic oil from Shell Lubricants, Houston.

“Oil Additive Helps Hydraulic Presses Save Energy,” about a new Dynavis oil additive from Evonik, Parsippany, N.J., that improves the viscosity index of hydraulic oils. It has been licensed to a number of oil suppliers and has been tested in Engel and Boy machines, yielding energy savings of 6% to 10%.

Related Content

Molder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreSecondary Injection Unit Provides Primary Benefits for Molder

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Read MoreCustom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More