The Accidental Molder

Peyton Owen came to plastics after decades in commercial real estate, but by empowering his employees through listening, he’s learning molding and success at D&M Plastics.

As 3 p.m. nears, Peyton Owen Jr.—Chip to all who know him—leaves the second-story conference room at D&M Plastics and heads down to the shop floor that it overlooks through a bank of windows. Every day at this time for the last seven years, the Burlington, Ill., custom injection molder (dmplastics.com) holds its all-hands “huddle” meeting, where employees share progress towards goals, new “lean” ideas to improve productivity, and safety insights from the plant and/or home, among other topics.

Marti Tremonti, D&M’s chief operating officer asks the assembled group if they have any “questions, comments or gratitudes.” After a pause, Owen, D&M’s owner, says with a laugh that he’s grateful the Chicago Bears won the day before. On the wall above the meeting, hangs a 4 × 6 ft banner with the company’s Team Charter. Below that sits a clock with “Safety First” printed on its face in red lettering.

D&M has held daily “huddle” meetings for more than 7 years, sharing company performance with its workers and asking them for “lean” and safety insights.

The meeting starts with D&M’s shipping and receiving supervisor updating the group on key metrics and goals—month-to-date sales, on-time shipments, etc.—with each data point greeted by claps. Next Tremonti asks the employees for any safety concerns from work or home, and the group brainstorms a solution for a colleague dealing with a hornet’s nest at his house.

Next up, the staff is asked to share any lean ideas they might have. Five are generated on topics ranging from dyeing materials to labeling parts, and all are written on a dry-erase board in blue marker. Below these new lean ideas are ones from the previous shift written in red. A picture is taken of the newest thoughts, which will be entered into a database and tracked to completion.

“We’re constantly asking our customers, ‘What’s your biggest problem, and let’s see if we can help you solve it.’”

Since the meetings began, D&M employees have brainstormed more than 12,000 ideas. Owen and Tremonti are the first to admit that most are not earth-shattering, some are fairly pedestrian, a few are real pearls and others are “retreads,” rehashing previous insights. In many ways, the output of the meetings isn’t the point. The “goal” is the meetings themselves and what they symbolize.

Tremonti says the huddles keep the “flow of communication open,” communication that is a key element of D&M’s success. In addition, even with “retread” ideas, new employees can can sometimes shed a different light on old observations. When workers engage with their jobs in a critical fashion every day, knowing they’ll have an outlet for any insights, the way they approach tasks changes. “We don’t dissuade team members from coming up with anything,” Tremonti says. “Whatever they throw out there, we’re receptive to it and make sure we write it down.”

“Listen, every shift doesn’t come up with five ideas every single day,” Owen says. “Sometimes it’s one, sometimes it’s three, and sometimes it’s six or seven. Some of them are kind of rehashes from the past, but we say, ‘There are no stupid ideas; there are no dumb ideas.’ We’ll write down anything people come up with, and yeah, some of them are repeated, but that’s OK.”

Owen remembers the perseverance that was required to maintain the meetings in their early days. “We did have to stick with it,” Owen explains. “After about two months, one of the guys said, ‘I think that’s it; I think that’s all the ideas we’ve got,’ and I said, ‘Well I don’t think so. Somehow I think there’s going to be more ideas.’”

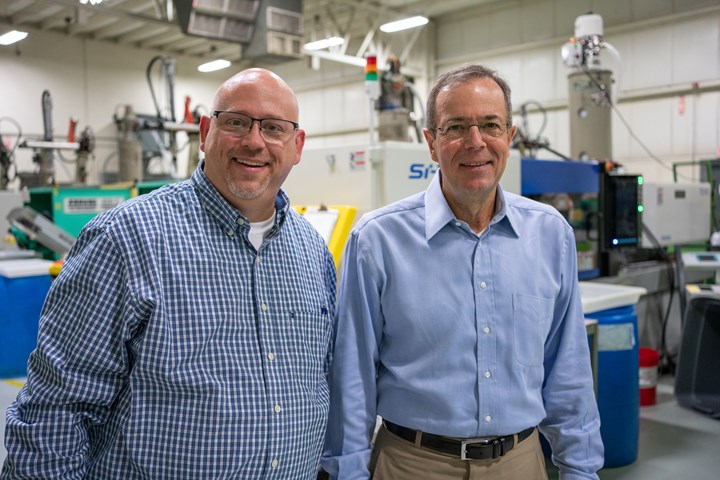

Peyton “Chip” Owen (left) and Marti Tremonti say daily “huddle” meetings keep open lines of communication with staff.

A company can’t continuously improve if it’s not constantly thinking about how it could do things better, and over those seven years, the meetings have generated ideas that dramatically improved D&M’s operations. Owen recalls when D&M’s head of maintenance put forward upgrading the plant’s aging, power-hungry halide lighting. The maintenance lead pursued the project; the local utility eventually chipped in; and the $30,000 investment paid for itself in less than a year. “That was all him—he did the whole thing,” Owen says. “That was a huge win, and we’ve benefited from it ever since.”

A New Career

Burlington, Ill., and D&M Plastics are a long way from New York City and commercial real estate. Owen came to custom molding after 30 years in the high-finance real-estate world, including nearly 20 years at Jones Lang LaSalle, before leaving to Equity Office Properties (EOP) in 2003, where he became its COO. When Blackstone acquired EOP in 2007 for $39 billion, Owen stayed on for a short time as its CEO before moving to New York and working for a private-equity real-estate firm. The Great Recession struck and after helping that firm clear its debts, Owen was ready for a change, although he didn’t know exactly what kind yet.

“I made the decision that I didn’t really want to work for anyone else,” Owen says, “and so I started looking for something to buy. I didn’t know I was going to buy a plastic injection molding company. I knew I didn’t want to buy a software company, and I knew I didn’t want to own a restaurant. I wanted to own a manufacturing company.”

High-volume, high-cavitation, geometrically complex stuff is our bread and butter, what we’re really good at.

Long versed in valuating and buying properties, Owen soon discovered that purchasing a business, particularly a manufacturer, was a different kind of deal altogether. He kicked the tires on everything from saw mills to a company that makes machines for forming, filling and sealing cartons. “I very quickly figured out that it’s very hard to buy small businesses. There’s a ready market for buildings and for real-estate assets, but it’s just really hard to buy a small company.”

When he first stumbled upon D&M in early 2012, Owen was impressed enough to make an offer. D&M’s previous owner initially rebuffed Owen, but when he came back in December of that year with essentially the same bid, the owner relented and sold. Owen closed in May 2013 and became a proud, if very green, injection molder.

Owen came to D&M Plastics as a plastics and injection molding newbie after spending three decades in commercial real estate.

“When I got here I didn’t know anything about injection molding,” Owen says. “I knew about running businesses, but I didn’t really know anything about the molding world.” To straighten that learning curve, Owen convinced the former COO to stay on. Roughly a year and a half ago, that gentleman left, and Owen hired Tremonti, who came with nearly three decades of automotive molding experience, including the last 17 years with Tier One supplier Magna.

More recently, Owen has also filled positions of head of engineering and of manufacturing, after two retirements. “There’s been a bit of turnover in the last year but we’re working our way through it,” Owen says. “Somebody once told me, ‘Every day is a new adventure when it comes to manufacturing.’”

Five Decades for D&M

The year 2022 is a momentous one for D&M as it will mark its 50th anniversary. The ISO 9001 and ISO 13485 company moved into its 56,000-ft2 facility, custom-built with underfloor utilities, in 1993. It currently runs 27 injection machines from 40 to 400 tons, with just shy of 40 employees. When Plastics Technology visited, a new 150-ton all-electric Toyo press was being installed—the second press added since the end of 2020. There’s space for 32 presses total. The company serves the medical, electronics, automotive, defense and industrial markets, offering assembly, in-mold labeling, overmolding, and insert molding.

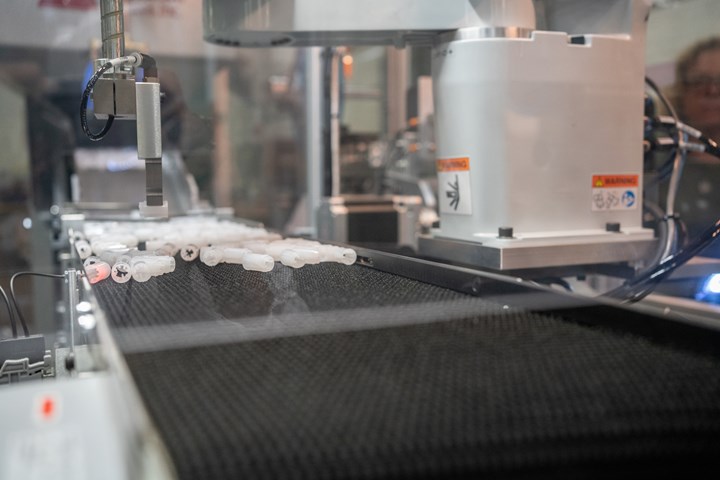

D&M focuses on molding high-volume, high-cavitation, geometrically complex parts from engineering resins.

The tool room focuses on maintaining the company’s 213 active tools, each of which are broken down and cleaned after a run, and D&M has shifted to all-domestic sourcing for molds, lining up three American moldmakers and is still vetting an additional two shops.

D&M currently runs three shifts, five days per week, plus Saturdays as needed. The average part molded at D&M weighs less than 25 g, with some parts as small as a half a gram. Most are molded in engineering resins from high cavitation tools with up to 96 cavities. “High volume, high cavitation, geometrically complex stuff is our bread and butter,” Owen says, “what we’re really good at.”

D&M has a complete tool room, and it breaks down tools after a run for cleaning and maintenance.

‘What’s Your Biggest Problem’

A key factor contributing to D&M’s success is its proactive approach to its customers’ needs. “We’re constantly asking our customers, ‘What’s your biggest problem, and let’s see if we can help you solve it,’” Owen says. One customer was ready to abandon a troublesome mold that it was running in-house. “We said, ‘Send us the mold, and we’ll see if we can fix it.’ And we did. That’s how we got most of their business.”

D&M proactively reaches out to customers to help them solve their problems—such a query was the impetus to add this automated labeling cell.

Two additions to D&M’s plant floor exemplify that problem-solving strategy. One customer had struggled with manually labeling in-house a product that was molded by D&M. D&M went to an automation specialist and commissioned a flexible cell to automate labeling and bring it under D&M’s roof. That cell now supports two customers and has dramatically reduced scrap that the first customer formerly experienced. D&M also added automated pad printing for another client that was sending that work out to be done manually. This investment has boosted the customer’s on-time delivery and can grow with the customer as the business expands.

D&M added pad printing capabilities to help a customer that had been manually printing parts in-house with unsatisfactory results.

Safety & Quality Inextricably Linked

D&M Plastics has had just one lost-time accident in 2500 days and counting. After Owen took over, a streak of 656 days was interrupted only to start a newer, longer run of 1874 days when Plastics Technology visited in late September.

“The company has always had a focus on quality, and you can’t have quality without safety or vice versa,” Owen says. Safety at the facility and even in the workers’ outside lives is discussed daily in the company huddles, and that repetition is key, according to Owen. “It’s just people knowing that if there is a safety issue, they need to tell somebody, and we’re going to do something about it.”

Further enforcing that ethos, D&M gives rewards for every 120 days without a lost-time accident or injury. Last time around, workers chose a roadside safety kit as their prize. “We try to get them as actively involved as possible in every aspect of our safety program,” Tremonti says.

Every D&M daily “huddle” devotes time to safety—at home and at work—an emphasis that has helped the company to have just one lost-time accident in more than 2500 days.

Shared Goals, Unified Vision

Among the goals D&M tracks and shares with its workers is to increase revenues 25% annually through 2025. “We’ll come close this year,” Owen says. “Right now, we’re up about 23% over last year, and interestingly, we were up slightly in 2020 over the year before.”

Owen isn’t alone in tracking D&M’s progress; all of his employees are as well, which is how he wants it. “Our employees ought to know what we’re doing every month,” Owen says. “They pretty much know how much we have to do in order to break even. I want them to be aware of that. What they do every day has an impact on our success. So every time we ship parts out the door, that’s when we make money.” D&M also provides profit sharing, which is paid out on a quarterly basis to all employees who work at least 390 hr during the quarter.

I’ve always had this view that in order for America to be strong, it has to make things, and I wanted to be a part of that.

D&M’s shop floor is a long way from the board rooms where Owen spent his first professional life. While he jokes that he’s “basically the finance guy” at D&M, he’s constantly improving on what has been a lifetime goal. “I wanted to own a manufacturing company,” Owen says, noting that he graduated from college with an engineering degree. “I’ve always had this view that in order for America to be strong, it has to make things, and I wanted to be a part of that.”

Tremonti and Owen say an open and inclusive company culture is helping D&M attract and keep skilled employees as it continues to expand.

Related Content

New CRM Streamlines Quoting for Automotive Molder

Eliminating the need to contact each supplier for every individual quote, a new CRM for automotive supplier Axiom Group tracks past quotes as well as industry history to generate fast, reliable RFQs and more.

Read MoreIndustrial Resin Recycling Diversifies by Looking Beyond Automotive

Recycler equips for new business in medical, housewares and carpeting.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreCarbon Fiber Reinforced Nylon 12 for Injection Molding

CRP Technology’s new composite is 100% recycled from Windform XT 2.0 IMG industrial 3D printing material.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More