Primex Plastics: The name evokes a long history of innovation and tradition in sheet extrusion. That’s understandable. The company was founded in 1965 with the goal of becoming the leader in the custom sheet extrusion industry. It started in Englewood, N.J., with three extruders. Today, it runs 125 extrusion lines in six plants in the U.S. and Great Britain. Extruders ranging in size from 4.5 to 8 in. produce sheet at widths from 54 to 180 in. and in thicknesses from 0.006 to 0.5 in. Company-wide, it carries a raw-material inventory of 70 million lb. Headquartered in Richmond, Ind., the company produces about 500 million lb of sheet per year, employs 1250 people, and has annual sales of about $500 million. Primex is part of ICC Industries, a New York-based holding company that owns various firms in plastics, chemicals and pharmaceuticals.

These are big numbers; and make no mistake, Primex Plastics Corp. is a big company. In manufacturing and other industries, the perception many have is that bigger companies tend to be slow moving and inflexible, whereas smaller firms are more inclined to be nimble and customer concentric. But under the leadership of long-time president Michael J. Cramer, Primex has maintained its entrepreneurial spirit despite its robust size. “Our decision-making process is guided by what’s good long-term, not necessarily what’s best for the next quarter,” Cramer says.

We’ll continue to invest to bring more innovative materials, capabilities, and high-quality products to the market.

Tim Schultz, Primex’s v.p. of sales and marketing, puts it this way: “I consider us a large national manufacturer that operates as a regional company. We’re quicker to react than most companies our size to the different needs of the customers we serve. We are large enough to handle any customer’s requirements, yet small enough to handle their needs. That happens to be our company’s motto, but it’s more than just words. It really guides what we try to do every day.”

Primex Plastics is about more than just sheet. It has recently undergone a rebranding effort to more clearly establish itself as a vertically integrated, “one company” business that links sheet extrusion with color-concentrate manufacturing on one end and fabrication on the other, says Schultz. In 1988, ICC bought the O’Neil Color plant in Garfield, N.J. Five years later, it bought a second color-concentrate plant in Jasper, Tenn. It has since renamed that operation Primex Color, Compounding & Additives. In 1987, ICC purchased plastics fabricator Woodruff Corp., now known as Primex Design & Fabrication.

“We’re customer-centric across all divisions,” says Cramer. “We’ll continue to make investments that allow us to bring more innovative materials, capabilities, and high-quality products to the market as we pursue the perfect solution to meet customer needs.”

The firm’s businesses in sheet, color and fabrication are supported by The John J. Farber Technology and Innovation Center, located in Richmond and named after the chairman of ICC. This world-class, A2LA accredited and ISO 9001 certified lab and innovation and development hub features state-of-the-art analytical equipment such as DSC, FTIR, TGA, QUV/xenon-arc weatherometer, and an array of testing platforms for physical properties and color analysis. At the center, Primex works with customers and prospects to identify and develop materials for their exacting applications.

The development facility is also furnished with processing equipment to produce tapes, color chips, molded test bars, sheet, and thermoformed parts so that Primex can analyze and quantify processing characteristics, perform complete physical testing, analyze color accuracy, and allow customers to see their materials in a finished state.

EYE FOR COLOR

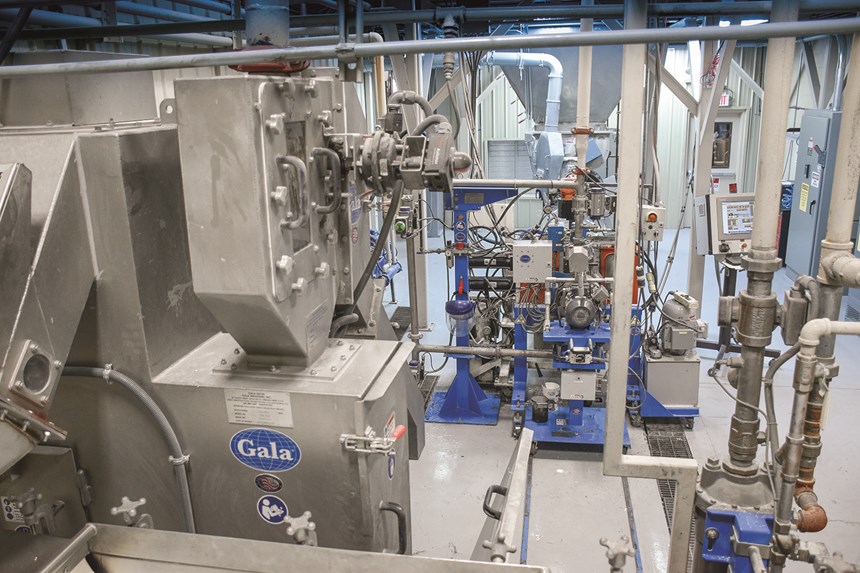

Primex Color, Compounding & Additives supports Primex’s sheet extrusion business—the sheet operation was a major customer of O’Neil Color—along with a variety of other customers. The Garfield operation has eight lines—seven twin-screw lines ranging from 27 to 64 mm, along with a 5-in. single-screw line—and focuses on highly customized orders in lots from 30,000 to 40,000 lb, says Robert Hillyer, general manager. The facility in Jasper, on the other hand, handles more generic compounds and utilizes larger production lines that focus on polyester color and performance additive packages.

Specialty compounds include the Faralloy product line providing flame suppression, UV stability, impact resistance, flexibility, and other performance enhancements to PP, PE and PS products. FaraColor color concentrates and polymer colorants provide special effects such as pearlescent, phosphorescent, granite/marble and metallics. Stock white and dry dispersions are also produced. Products are supplied to markets such as automotive, packaging, building/construction, medical, and sporting goods. “We’re not married to a particular industry,” says Hillyer. “We have our eggs in a lot of different baskets.”

We are a company that’s extremely diverse in terms of the markets we serve. It’s a key part of our business strategy not to be overwhelmingly tied to one market or another.

Production lines at the Garfield operation are gravity fed by mixers housed on a mezzanine. With more than 6000 different formulations on hand, the Garfield plant has condition sheets for every product it runs, giving operators easy access to preset processing recipes. Four small injection presses are used to produce color chips for color matching and quality control. The facility also has a two-roll mill, two lab-scale sheet lines, and a lab-scale rotomolding machine, as Garfield supplies dry color for this process. The lab is also equipped with the full range of testing equipment, including spectrophotometers, melt indexers, moisture analyzers, light boxes, and more. Hillyer reports that Garfield’s business was up 29% in 2017 from the year before, and that the first quarter of 2018 is also tracking well.

SHEET FOR A VARIETY OF APPLICATIONS

Primex runs sheet in a wide range of materials, with each plant having coextrusion capacity. Most of the sheet Primex extrudes is sold through distributors and directly to thermoformers as either rollstock or cut sheet. It also has established a return program with customers that results in recycling more than 150 million lb/yr of post-industrial scrap, mostly thermoforming skeletal trim.

Primex works with customers to select the right material and blend so that the sheet is fine-tuned to the application and it has the proper “sag” during the thermoforming operation, assuring even material distribution and wall thickness.

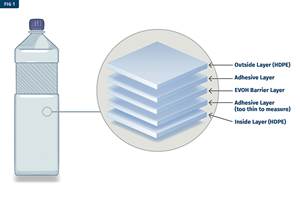

Applications for Primex’s PE products are far flung. One of its HDPE product lines, for example, is aimed at trays, food packaging, small dunnage, or any other parts that require low-temperature impact. It also works well for small lawn-tractor parts and many other small tool components. Primex offers a line of LDPE sheet for packaging applications such as pharmaceuticals, dried fruits, and meats. It is also being used for dunnage in the computer industry, as well as for drum liners. An HMW-HDPE sheet line targets feeders, pallets, truck-bed liners, portable toilets, and totes, among others.

Primex recently introduced a new swirl-patterned HMW-HDPE product that can be color coordinated to meet customers’ requirements. Thickness of the sheet ranges from 0.100 to 0.350 in., and widths are up to 90 in. The swirl pattern can be designed to fit a variety of uses that are product-specific for each customer’s needs. The three-layer structure consists of an HMW-HDPE substrate with a three-color swirl cap of HMW-HDPE that can be on one or both sides of the sheet. Applications so far have consisted of playground equipment, camouflage deer blinds, canoes, and other sporting equipment.

Primex also runs a wide range of ABS sheet for tub/shower surrounds, pickup truck caps, boat accessories, automotive trim parts and computer housings. Primex runs copolymer PP sheet for food and medical packaging, as well as orthopedic and prosthetic applications. Talcor calcium carbonate-filled grades are used in microwavable food packaging. The company runs PETG for food trays, cosmetic packaging, thermoformed clamshells and blister packaging.

We are large enough to handle any customer’s requirements, yet small enough to handle their needs.

Primex is also reportedly North America’s largest producer of custom PS sheet. It is produced in up to five layers for applications that include thermoforming, fabricating, printing (silk-screen, flexographic, lithographic and register grade), high gloss, chemical resistance, moisture barrier, marbleized, pearlescent, and two-color sheet. For food and medical-device packaging, Primex supplies PS sheet extruded from 100% virgin resins.

The company also offers biobased sheet products. An agricultural-based material is used to produce Biograph.ics sheet that is said to offer higher heat resistance and greater impact strength than sheet processed from other biobased materials. What’s more, this sheet has demonstrated superior ink receptivity over petroleum-based products for graphics.

Primex’s Absolve product line is a compostable sheet for applications that currently use PS, PP, and PE. Absolve incorporates special polymer technology to facilitate degradation of litter and commercial or household compost, as well as in landfill disposal. It is available in sheet or roll for printing or forming.

Says Schultz, “We are a company that’s extremely diverse in terms of the markets we service. It’s a key part of our business strategy not to be overwhelmingly tied to one market or another.”

Throughout its operation—including its largest sheet facility in Richmond, which is equipped with 40 lines—extrusion lines are organized by polymer family. All are equipped with gravimetric blending and on- and offline gauge control. Primex buys flat dies from established suppliers and fine-tunes them to the specific application. States Schultz, “We have enough capacity to fill even specialty orders quickly. We run lines around the clock. Our turnarounds are tight. Our order minimums are 1000 lb for wide sheet made from specialty materials, and our lead times there are two to three weeks.”

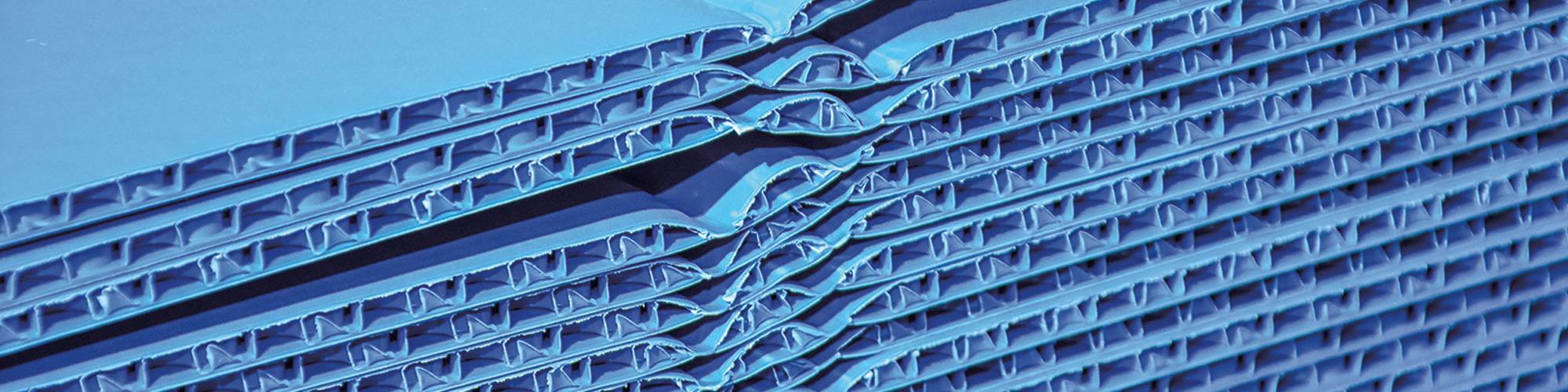

Primex Plastics’ most unusual PP sheet is called Bubble-X, a three-layer, lightweight, rigid coextruded board made by a proprietary process. It has a thermoformed honeycomb core and two solid, skin layers with smooth, matte, or embossed finishes. These skin layers are corona-treated to improve printing performance.

Primex can laminate decorative or specialty films to the board. Bubble-X is used to fabricate sleeve packs, which when combined with a matching pallet and cover, are lightweight alternatives to corrugated paperboard and molded containers, including internal dunnage.

FABRICATION SPECIALISTS

Primex Design & Fabrication takes its sister companies’ corrugated and solid sheets and turns them into packaging solutions. Housed a short drive from the Richmond sheet extrusion plant, this business unit makes products like corrugated returnable bins, totes, trays and point-of sale signage; protective packaging; customized work-in-progress packaging; and corrugated signs. It’s heavily focused on protective packaging with an emphasis on Tier 1and 2 automotive suppliers, and recently hired a product manager for this area.

Primex Design & Fabrication has multiple die cutters, routers and presses that can handle virtually any size sheet application in virtually any material thickness. There are also sonic welders and heat sealers; printers for spot colors and four-color processes; automated wire-forming machines for tote and dunnage reinforcement; foam cutters; and laminating, gluing, sewing, and kitting operations.

States Doug Borgsdorf, business-unit director for Primex Design & Fabrication and Primex Color, Compounding & Additives, “By vertically integrating, we have created a ‘one company’ philosophy to bring customers the best quality and pricing available in the industry. We are part of the entire supply chain, so customers never have to worry about delivery, consistency or material that meets their exacting specifications.”

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreFlexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

Read MoreMeasuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More