THERMOFORMING AT NPE: Machines Get Faster, More Flexible & Precise

NPE PREVIEW

They’re more energy-efficient, as well.

In thermoforming, a scant few suppliers revealed what they will be bringing to NPE2015 in time for this article. Among those who did, the emphasis was on high-speed packaging lines for thin-gauge sheet. There was one bit of news in machines for non-packaging sheet, as well as a new product for post-forming.

Kiefel will display its Speedformer KMD 90 pressure former at a North American show for the first time. Some 70 processors got a glimpse of the machine last September during Kiefel’s open house in Livonia, Mich. One such line is operating the U.S., two more have been ordered, and numerous other projects are in the discussion stage, Kiefel states.

Kiefel says the new machine “opens up a new dimension” in thermoformed packaging by virtue of its fast cycling—up to 40 dry cycles/min—and larger forming area—34 x 36 in. It can handle sheet widths to 36.4 in. and accommodate a wide range of materials, including PS, OPS, PP, PE, PVC, PET, PLA, and CPET.

New features of the KMD 90 include high-output ceramic heaters designed to enable the sheet to quickly and efficiently absorb energy. This results in increased cycle speeds, even with a smaller oven footprint. The servo-driven forming station offers a third-motion plug drive for either the upper, lower, or both platens. With more than 44 tons of clamping pressure, the forming station can generate up to 75 psi of pressure to ensure part quality.

Tool loading on the KMD 90 is accomplished via a unique elevator that can accommodate most quick-change tool packages. A combination of “kiss cut” technology, servo-position control, and patented torsion rods is said to provide precise accuracy. This latter feature also reportedly promotes increased knife life and reduced setup time while improving part quality by eliminating creation of particulates during cutting. High cutting force at the trim station permits a large knife area to be used.

A servo-driven down stacker places finished products in predetermined stack heights on a conveyor belt below the sheet level. The conveyor is installed in the index direction to reduce overall floor space, while providing a safe and ergonomic packing area to reduce operator fatigue.

A Siemens Simotion control system with a touchscreen interface is said to make the machine easier to set up and operate. The intuitive interface allows for quick navigation from screen to screen. If an operator needs help to configure a product recipe, Kiefel’s Computer Aided Teaching program is said to be able to “fill in the blanks.” The program will automatically configure the machine settings just by requiring the operator to answer a few basic questions.

At NPE2015 this month, Illig will demonstrate the IC-RDKP 72 automatic forming machine, which is equipped with separate forming and punching stations. At the show, the machine will produce a hinged food package made of APET rollstock.

The machine has a maximum forming area of about 30 x 21 in. The line will be equipped with a hole-punch press positioned between the forming station and the steel-rule punch press. Its purpose is to apply vent openings to packages. The line runs at up to 50 cycles/min with a six-up mold.

Illig’s new IC (Intelligent Control) concept will also be shown. This controller is designed to let the operator maximize the efficient operation of the entire line. Using the “accelerated mold change” IC module, for example, saves mold-change time while ensuring reliability. The operator receives targeted information on the screen for all tasks required in conjunction with a mold change, along the whole thermoforming line. This helps prevent errors right from machine startup.

At its booth, Illig will also be discussing IML decoration of thermoformed packaging as well as high-volume thermoforming of coffee capsules.

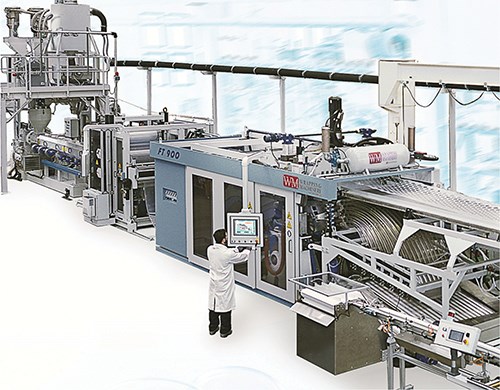

During NPE, WM Wrapping Machine Co. will show the largest of its Tilting Machine Series, the FT 900. The lower platen tilts on this punch-and-die thermoforming machine, which has a tooling area of 34.6 x 20.4 in. and generates 82.5 tons of clamping force.

The machine will produce 2.9-in.-diam. PP yogurt cups on a 54-cavity mold. In this demonstration, WP will be running sheet of ExxonMobil’s PP6262 grade, which the machine builder says contributes to fast setup times and energy efficiency by providing fast crystallization rates and easy mold release.

Based in Switzerland, WM last year opened a 40,000 ft² technical center in Elkhorn, Wis.

For thick-sheet industrial applications, Geiss will show its model T10 vacuum forming machine that now offers servo-driven axes as standard features. This means the top and bottom platen, clamp frame, top and bottom heater banks, and sheet-loader movements are all driven by energy-efficient servo motors.

Geiss says this results in a machine with 60% faster movements, higher energy efficiency, and a smaller footprint than its T9 predecessor. Moreover, the T10 is equipped with a new higher-efficiency cooling system that reportedly improves cooling time by 30%. This machine was shown in prototype form at Fakuma 2014 last fall in Germany.

NEWS IN ROUTERS

For post-forming operations, Diversified Machine Systems (DMS) will be showing a 5-axis CNC router at the show. The machine is equipped with numerous new features that are said to enhance safety. These include air-pressurized bellows, tool-changer doors to protect the outside of the work envelope, cool-air guns for keeping contaminants away from runner blocks, and fully enclosed machining for safety and dust containment.

Fagor 8065 CNC Control is available as a standard offering on most of DMS’s 5-axis CNC routers. It features a Tool Inspection mode that allows the operator to pause the program being executed, explore aspects of the machine without losing position, and resume at the point-of-program interruption. This feature reportedly anticipates any conditions that an operator may run into during the execution of a program and provides a solution.

Related Content

Winners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreSheet Extrusion, Thermoforming Tips for PLA/aPHA Blends

Biopolymers like PLA and PHA are able to meet sustainability goals while also delivering the performance attributes needed in rigid food packaging. Here’s what testing has shown.

Read MoreOrigin Materials Unveils CapFormer for Producing PET Caps

Factory acceptance test completed at commercial scale.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More